Energy-saving washing system for textile cloth

A cloth and water washing technology, applied in the field of textile printing and dyeing, can solve the problems of large consumption of auxiliaries, water waste, environmental pollution, etc., and achieve the effects of reducing discharge, saving rinsing water, and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

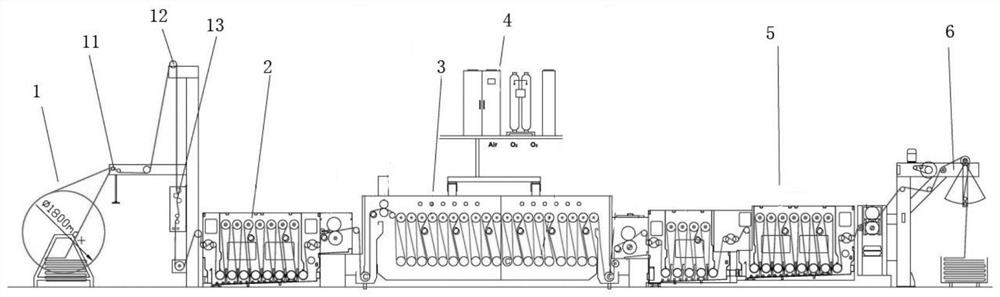

[0044] Such as figure 1As shown, the textile cloth energy-saving water washing system includes:

[0045] Cloth feeding device 1, through which the woven cloth enters the washing system;

[0046] The pre-washing device assembly 2 is connected to the cloth feeding device 1 to pull the textile cloth into the pre-washing device assembly 2 for pre-washing;

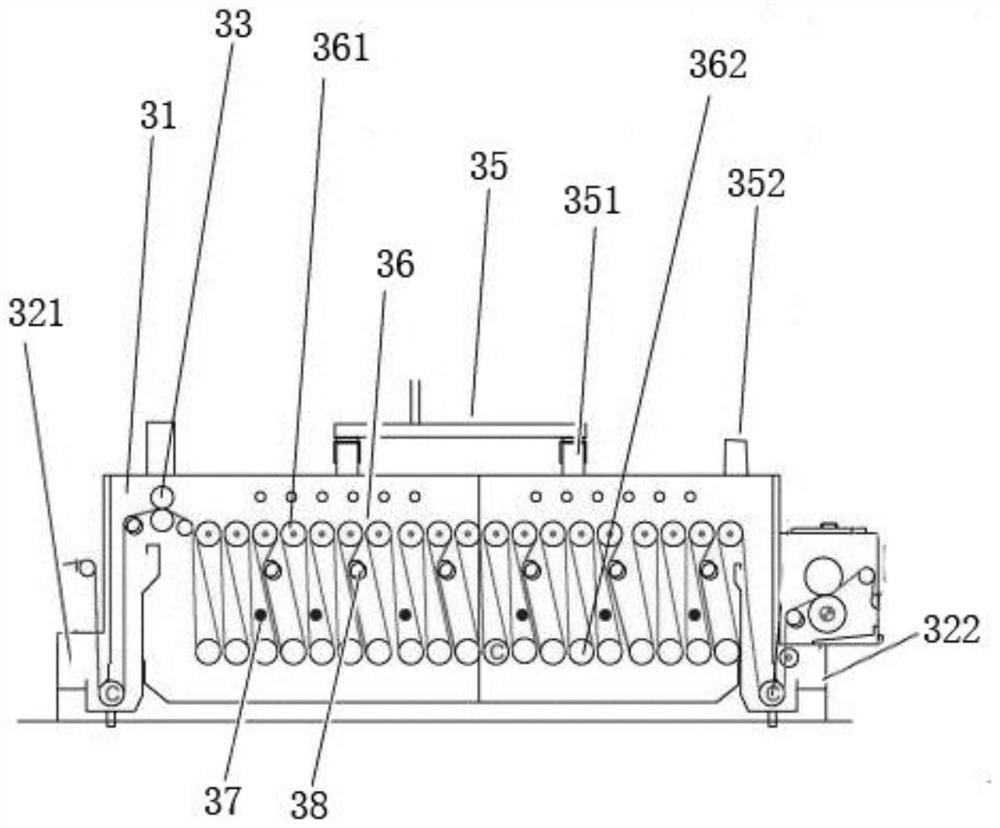

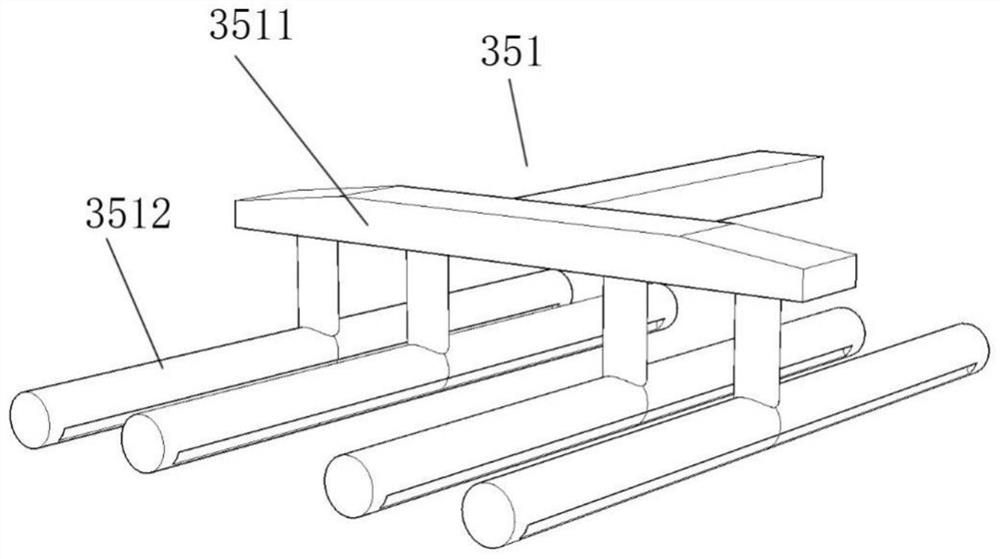

[0047] The ozone finishing assembly 3 is connected to the pre-washing device assembly 2 to pull the textile cloth from the pre-washing device assembly 2 into the ozone finishing assembly 3 for ozone finishing;

[0048] The ozone production device 4 is connected to the ozone finishing assembly 3 to supply ozone to the ozone finishing assembly 3;

[0049] The washing device assembly 5 is connected to the ozone finishing assembly 3 to draw the textile cloth from the ozone finishing assembly 3 into the washing device assembly 5 to wash the textile cloth;

[0050] The cloth outlet device 6 is connected to the washing device assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com