Self-fading textile wastewater filtering device and using method thereof

A technology for textile wastewater and filtration equipment, which is applied in textile industrial wastewater treatment, water/sewage treatment equipment, filtration treatment, etc. It can solve the problems of affecting work efficiency, high chroma, and difficulty in cleaning wool fibers, etc., to reduce the difficulty of treatment , Improve the interception effect, improve the effect of the fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

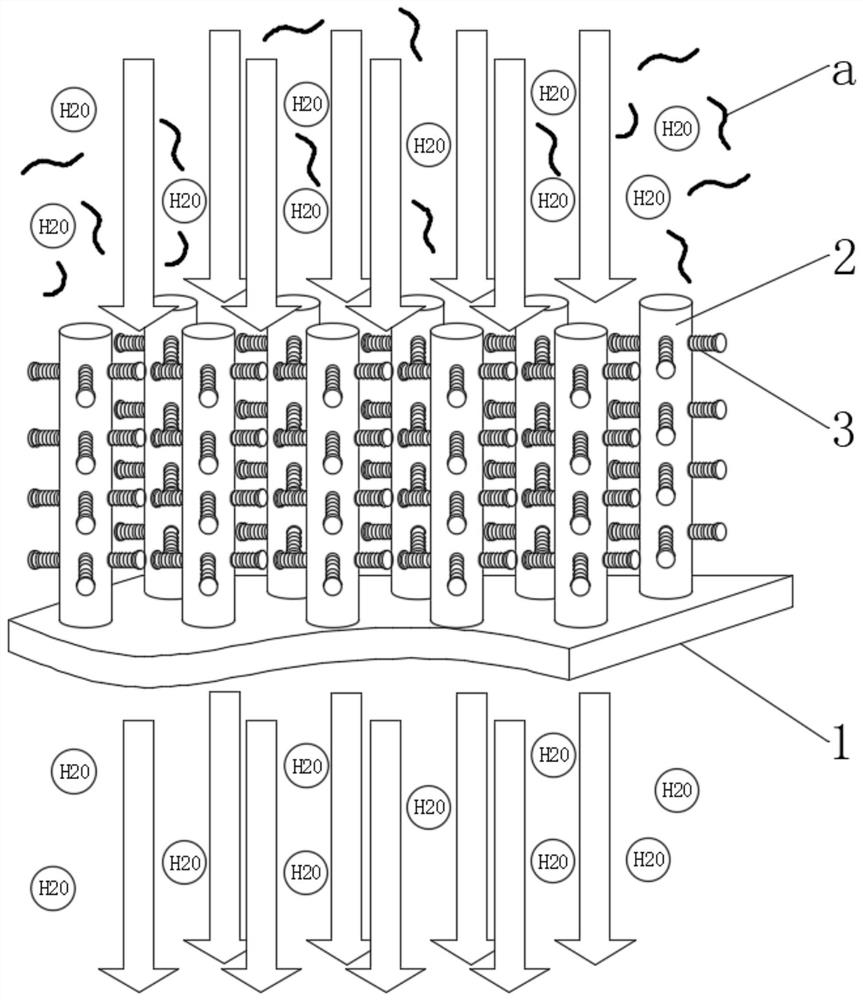

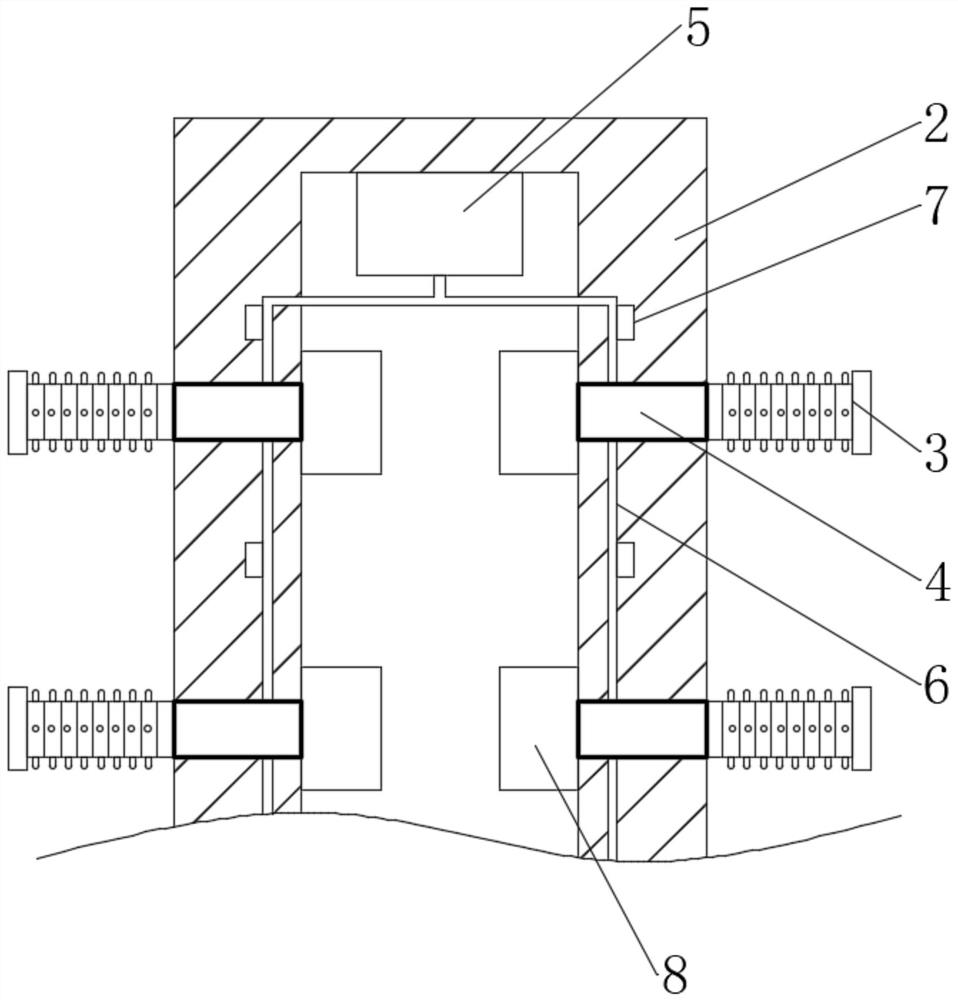

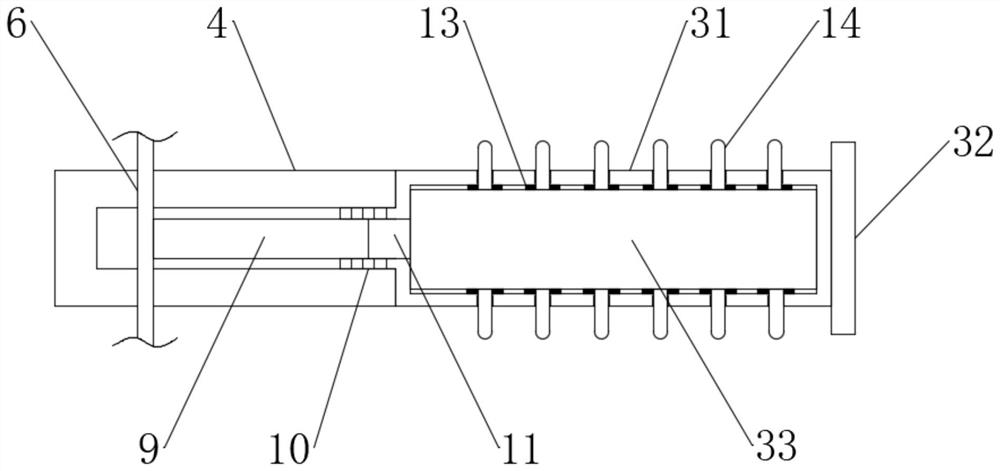

[0049] see Figure 1-2 , a self-fading type textile wastewater filter equipment, including a filter purification component 1, the upper end of the filter purification component 1 is fixedly connected with a plurality of evenly distributed pre-splitting columns 2, and the outer ends of the pre-splitting columns 2 are equipped with multiple rows of annular arrays. The telescopic intercepting column 3, the distance between a pair of pre-splitting columns 2 and the length ratio of the telescopic intercepting column 3 is 1:0.5-1, and the telescopic intercepting columns 3 on the adjacent pre-splitting columns 2 are arranged alternately, which can A tight spatial interception network is formed, which greatly improves the interception effect on wool fibers a in the textile wastewater. An electric control cavity is excavated at the inner end of the pre-dividing column 2, and a plurality of telescopic interception columns 3 are excavated on the side wall of the electronic control cavity....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com