Textile wastewater treatment mechanism based on microbial technology and using method thereof

A microbial technology and textile wastewater technology, applied in the field of textile wastewater treatment institutions based on microbial technology, can solve problems such as unfavorable biofilm renewal, reduced purification capacity, anaerobic film thickness, etc. The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

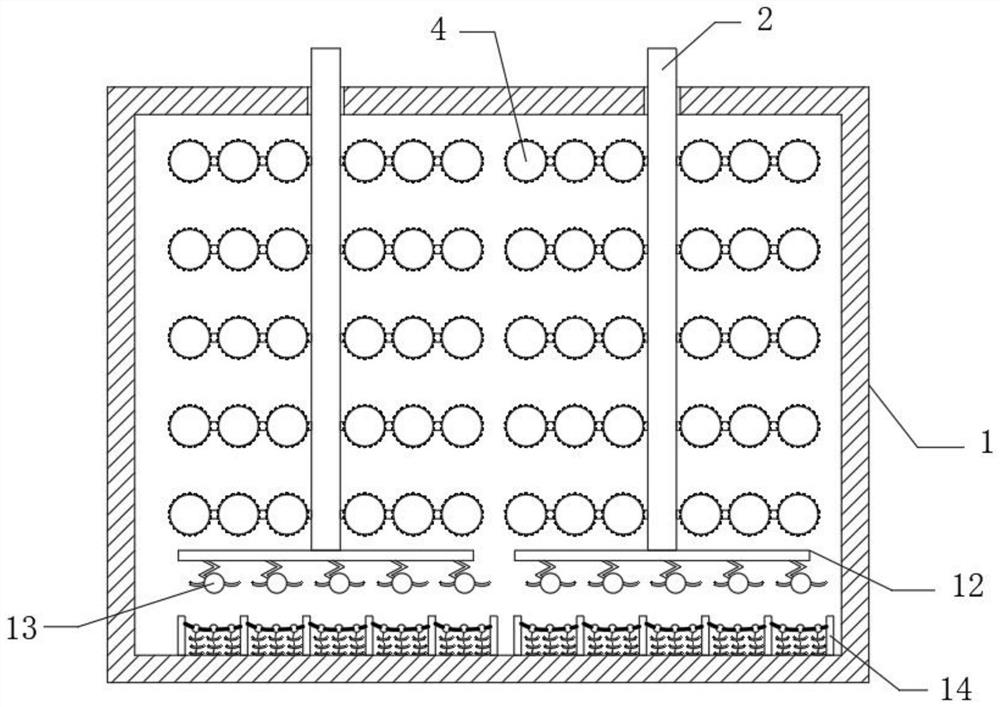

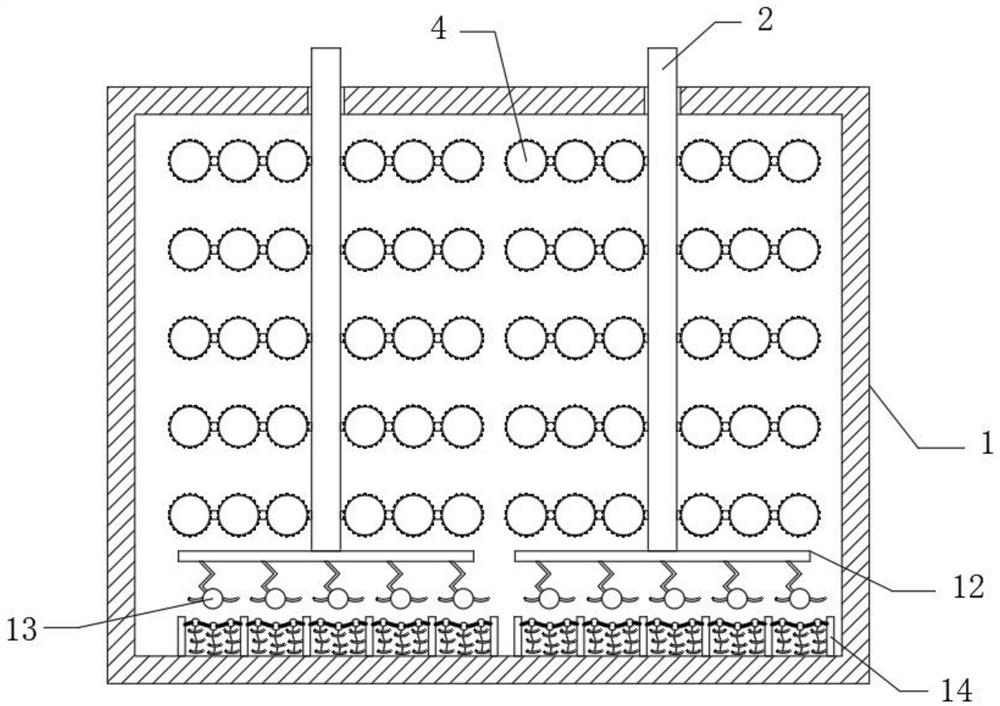

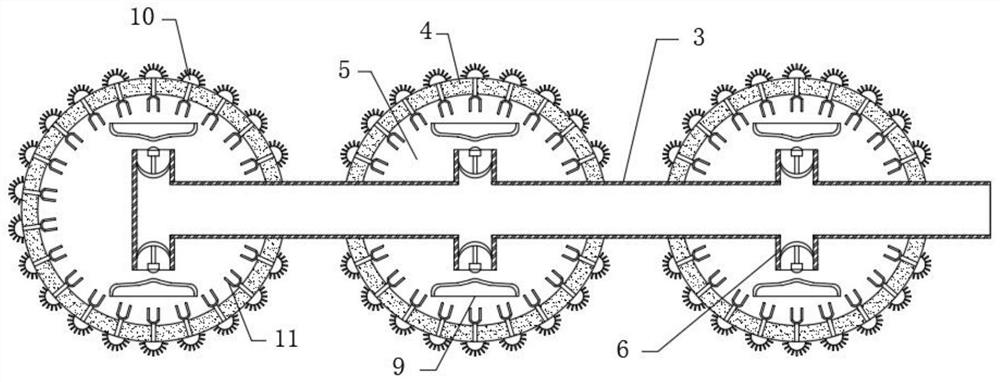

[0046]SeeFigure 1-8 , Textile wastewater treatment mechanism based on microbial technology, including tank 1, please refer toFigure 1-2 A plurality of rotating rods 2 are rotatably connected to the pool body 1, and the rotating rod 2 penetrates the upper end side wall of the pool body 1, the rotating rod 2 is a hollow rod body, and the side wall of the rotating rod 2 is connected with a plurality of vent pipes 3, Each vent tube 3 is connected with a plurality of biofilm loading balls 4 in series, and the inside of the biofilm loading sphere 4 is provided with a cavity 5, and the side walls of the ventilation tube 3 in each biofilm loading sphere 4 are connected with each other. The connecting pipe 6 communicates with the cavity 5, and the connecting pipe 6 is arranged perpendicular to the vent pipe 3 to facilitate the hammer 8 to hit the vibrating member 9 better. The inner walls of both ends of the connecting pipe 6 are fixedly connected with Elastodynamic membrane 7, seeImage 6 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com