Textile wastewater treatment method based on Fe3O4/CNTs composite dispersed electrode

A technology for textile wastewater and treatment method, which is applied in the textile industry wastewater treatment, water/sludge/sewage treatment, water/sewage treatment and other directions, can solve the problems of the electrode efficiency to be improved, the separation of refractory products, and the energy consumption to be reduced. , to achieve the effect of high reuse times, large processing capacity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

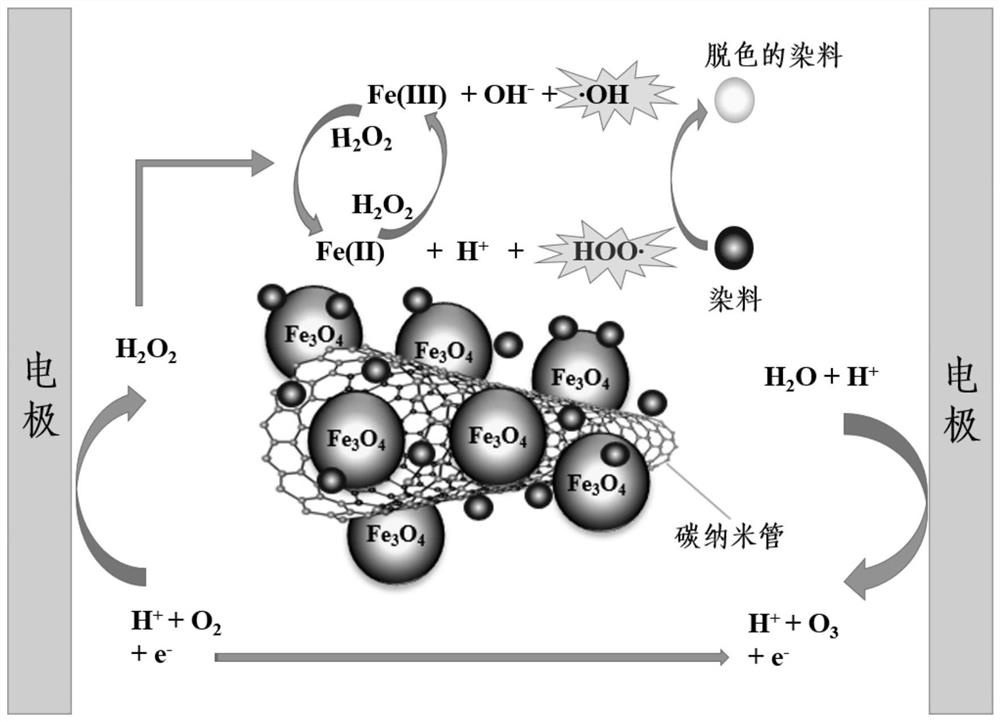

Method used

Image

Examples

Embodiment 1

[0060] The preparation method of ferric oxide / multi-walled carbon nanotube composite material comprises the steps:

[0061] (1) Weigh 100mg of multi-walled carbon nanotubes and add them to 30mL ethylene glycol, 10mL polyethylene glycol and 1.35gFeCl 3 ·6H 2 In the mixed solution of O composition, add the sodium acetate of 3.6g again, put into the supersonic cleaner 1h;

[0062] (2) Seal the mixed solution treated in step (1) in a stainless steel reaction kettle with a Teflon lining, and put it into a 200° C. electric constant temperature blast oven for 12 hours. After cooling to room temperature, wash it repeatedly with ethanol and water, then filter it with a vacuum pump, and dry it in an oven at 60°C to obtain the Fe3O4 / multi-walled carbon nanotube composite material Fe 3 o 4 / NWCNT.

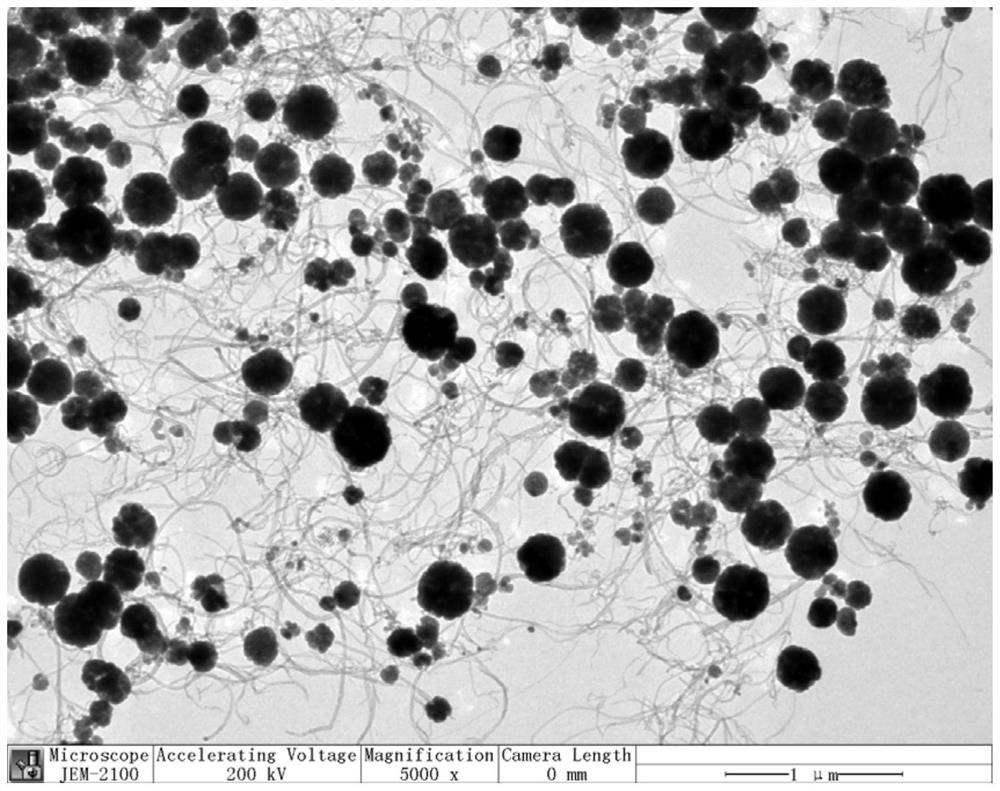

[0063] The transmission electron microscope image of the prepared Fe3O4 / multi-walled carbon nanotube composite material is as follows figure 1 shown, from figure 1 It can be seen that: m...

Embodiment 2

[0065] The preparation method of ferric oxide / multi-walled carbon nanotube composite material comprises the steps:

[0066] (1) Weigh 100mg of multi-walled carbon nanotubes and add to the mixture of 20mL ethylene glycol, 15mL polyethylene glycol and 1.5gFeCl 3 ·6H 2 In the mixed solution of O composition, add the sodium acetate of 3.0g again, put into the ultrasonic cleaning device ultrasonic treatment 2h;

[0067] (2) Seal the mixed solution treated in step (1) in a Teflon-lined stainless steel reaction kettle, and put it in an electric constant temperature blast oven at 220° C. for 16 hours. After cooling to room temperature, wash it repeatedly with ethanol and water, filter it with a vacuum pump, and dry it in an oven at 70°C to obtain the Fe3O4 / multi-walled carbon nanotube composite material.

Embodiment 3

[0069] A kind of textile wastewater treatment method based on the ferroferric oxide / multi-walled carbon nanotube composite dispersed electrode of embodiment 1, comprises the steps:

[0070] Get 60mL of disperse blue 2BLN solution whose mass concentration is 25mg / L, add 1g / L sodium fluoroborate (NaBF 4 ), form the electrolyte, adjust the pH of the solution to be 3, and the Fe of 75mg embodiment 1 3 o 4 / NWCNT was added into the electrolytic cell as a dispersed electrode, and a DC voltage of 17V was applied between the positive and negative plates, and the reaction was performed for 3h.

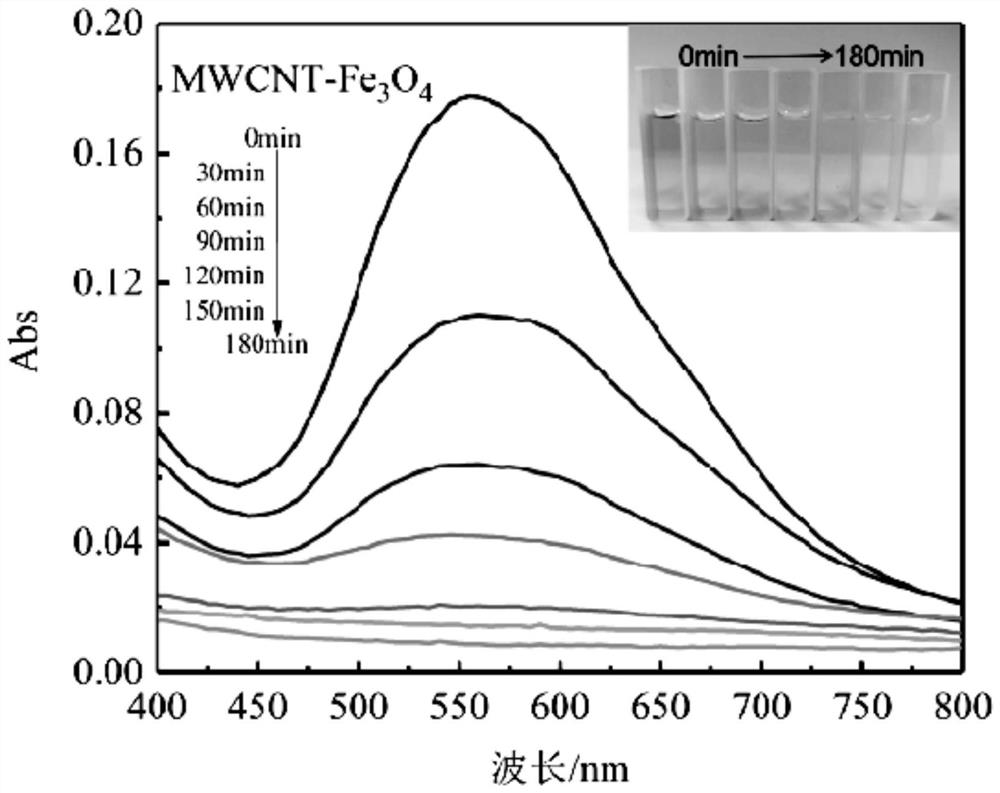

[0071] By testing, the final decolorization rate is 98.79% (see specifically image 3 ).

[0072] By strong magnet adsorption, pure water washing, filtration, to the Fe of embodiment 3 3 o 4 / NWCNT was recovered, and the recovery rate reached 98.1%, and then the decolorization process of Example 3 was repeated 10 times, and the decolorization rate reached 97.20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com