Failure self-desorption type textile wastewater treatment device

A textile waste water and treatment device technology, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of filter material clogging, frequent clogging, and reduce the filtration efficiency of textile wastewater, etc., so as to improve the clogging the effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

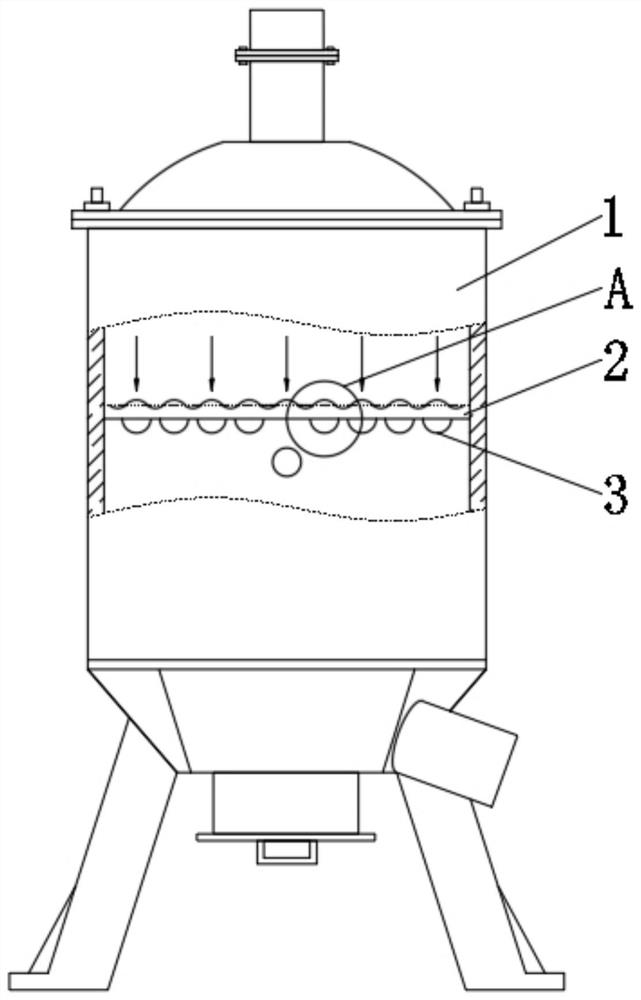

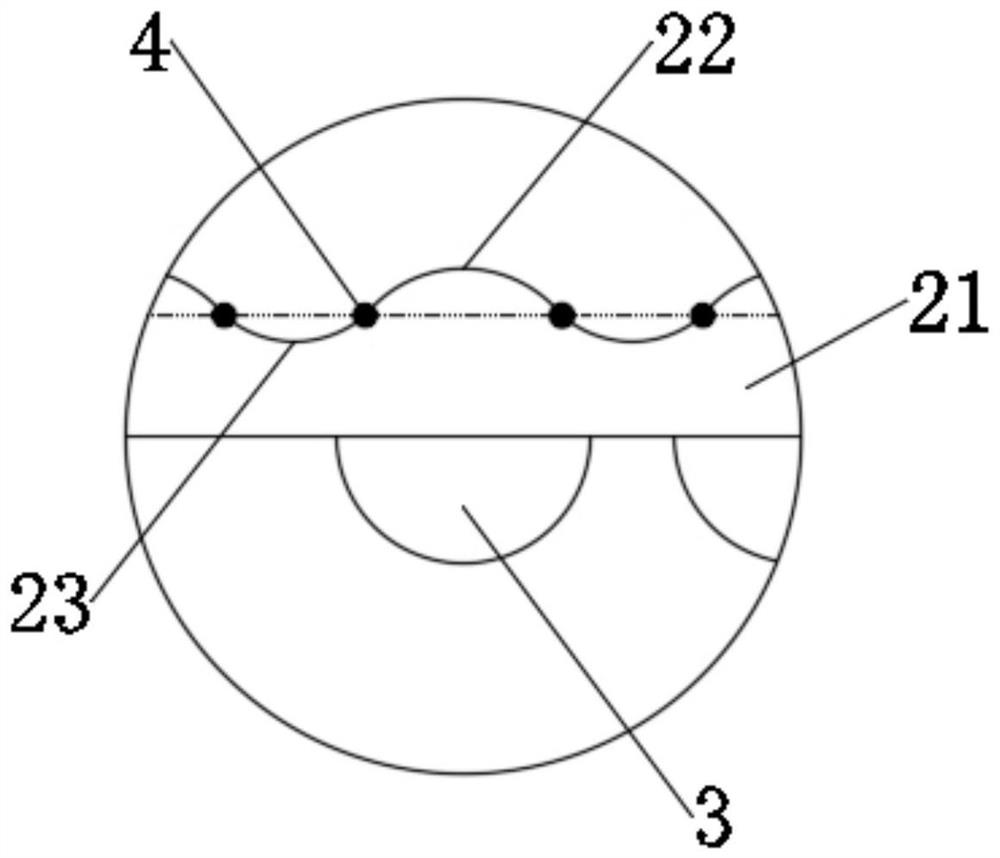

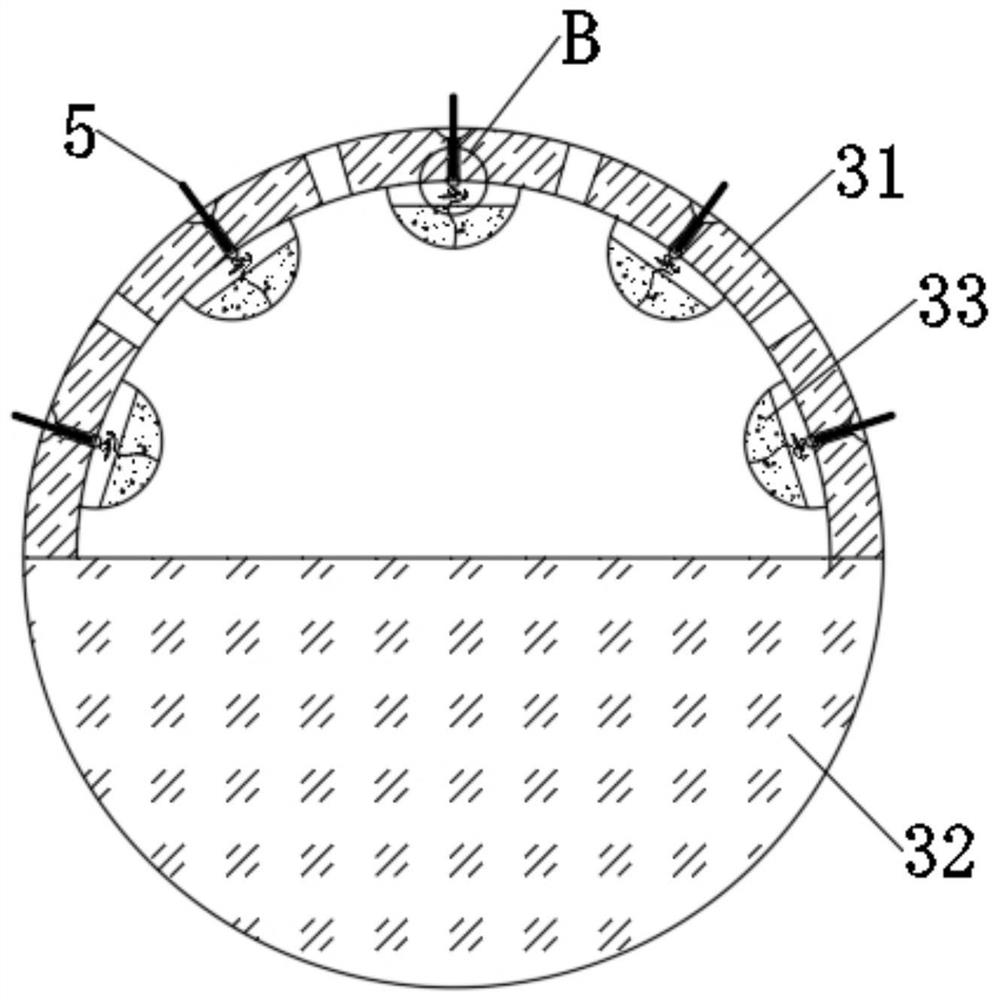

[0042] see Figure 1-2 , a failure self-desorption type textile wastewater treatment device, including a filter tower 1, the upper and lower ends of the filter tower 1 are respectively equipped with a water inlet pipe and a water outlet pipe, and a filter layer 2 is fixedly installed in the filter tower 1, and the filter layer 2 includes a fixed plate 21. A plurality of convex filter ends 22 and concave dirt collection ends 23, the convex filter ends 22 and concave dirt collection ends 23 are alternately arranged on the upper surface of the fixed plate 21, and the convex filter ends 22 and the concave dirt collection ends 23 are kept continuous, The connection between the fixed plate 21 and the convex filter end 22 is inlaid with a magnetic block 4. The lower end of the fixed plate 21 is provided with a plurality of plugging holes matching the convex filter end 22, and the plugging holes are located directly below the convex filter end 22. A matching dredging ball 3 is movably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com