Yarn dyeing and finishing wastewater treatment equipment and treatment process thereof

A technology for dyeing and finishing wastewater and treatment equipment, which is used in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. To achieve the effect that is conducive to continued processing, good effect and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

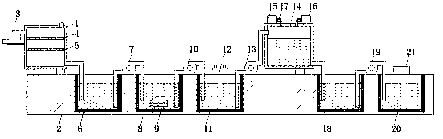

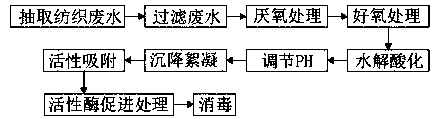

[0028] see Figure 1-2 , the present invention provides a technical solution: a kind of yarn dyeing and finishing wastewater treatment equipment, comprising a filter box 1, characterized in that: the bottom of the filter box 1 is provided with a ground 2, and the top of the ground 2 is fixedly connected with the filter box 1 to filter The left side of the box 1 is fixedly connected with the first sewage pump 3, and the water inlet of the first sewage pump 3 is connected with the waste water collection pool through the pipeline. The cavity is fixedly connected with a second filter screen 5, the second filter screen 5 is located at the bottom of the first filter screen 4, and the top of the ground 2 is sequentially provided with an anaerobic pool 6, an aerobic pool 8, a hydrolytic acidification pool 11, The flocculation tank 18 and the adsorption tank 20, the top of the ground 2 is fixedly connected with the adjustment box 14, the adjustment box 14 is located between the hydroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com