Treatment equipment for chemical fiber textile wastewater

A technology for textile wastewater and treatment equipment, which is applied in the textile industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. The effect of increasing the amount of air bubbles, realizing the reaction contact, and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

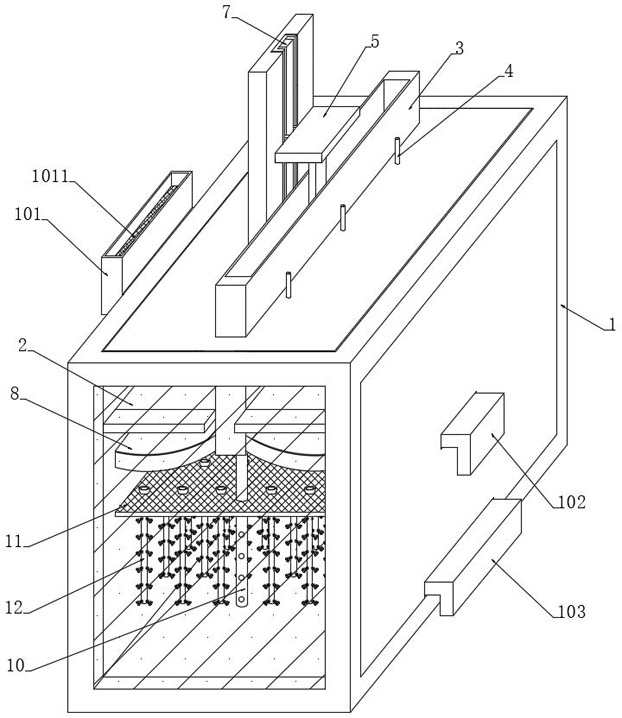

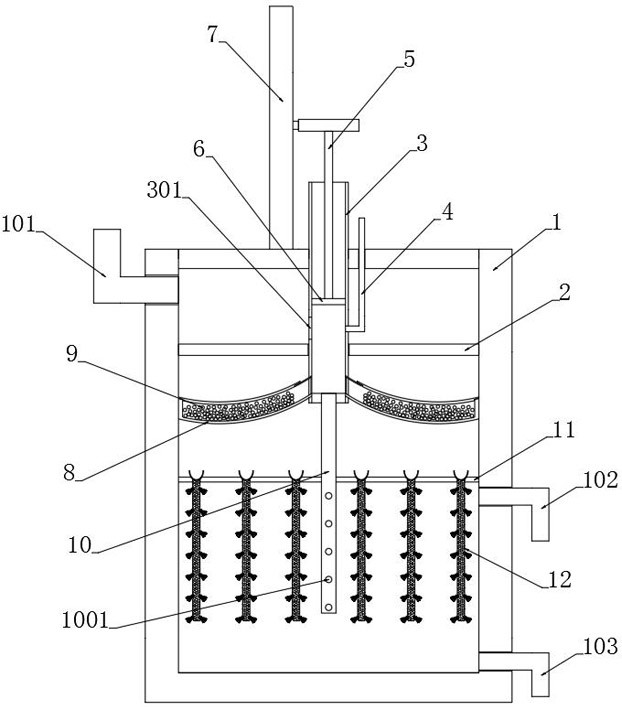

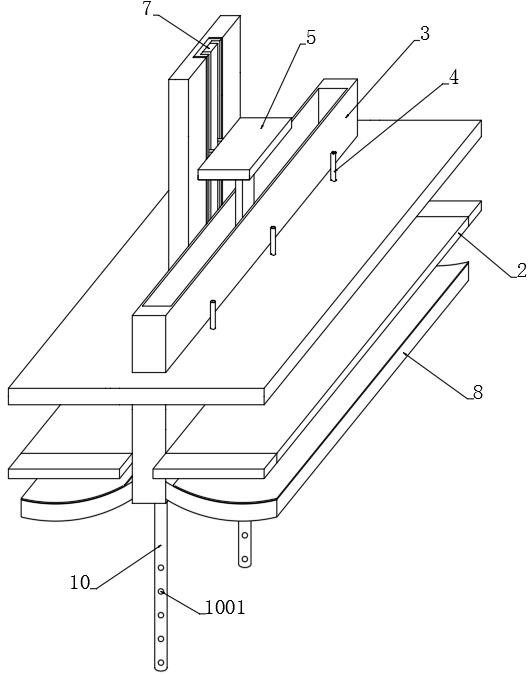

[0040] see Figure 1-4 , a treatment equipment for chemical fiber textile wastewater, including a treatment pool 1 with a cover plate, the interior of the treatment pool 1 near the top is fixedly connected with a partition plate 2, and the partition plate 2 separates the interior of the treatment pool 1 into an upper feed chamber and the lower treatment chamber, the outer wall of the upper feeding chamber is provided with a water inlet channel 101, and a filter screen 1011 is embedded in the water inlet channel 101, and the waste water to be treated is introduced through the water inlet channel 101 and filtered by the filter screen 1011 for preliminary filtration to filter out larger fiber impurities in the wastewater. The outer walls of the upper and lower ends of the lower treatment chamber are respectively provided with a drainage channel 102 and a sewage channel 103. The clear liquid and sediment are discharged, and the specific positions of the two are set and installed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com