An air flotation machine for down production wastewater treatment

A technology for the production of wastewater and air flotation machines, which is applied in flotation water/sewage treatment, separation methods, filtration and separation, etc., can solve the problems that impurities cannot be completely floated, the collection of floating impurities is troublesome, and precipitation is easily generated, and the structure is achieved. Simple, thorough and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

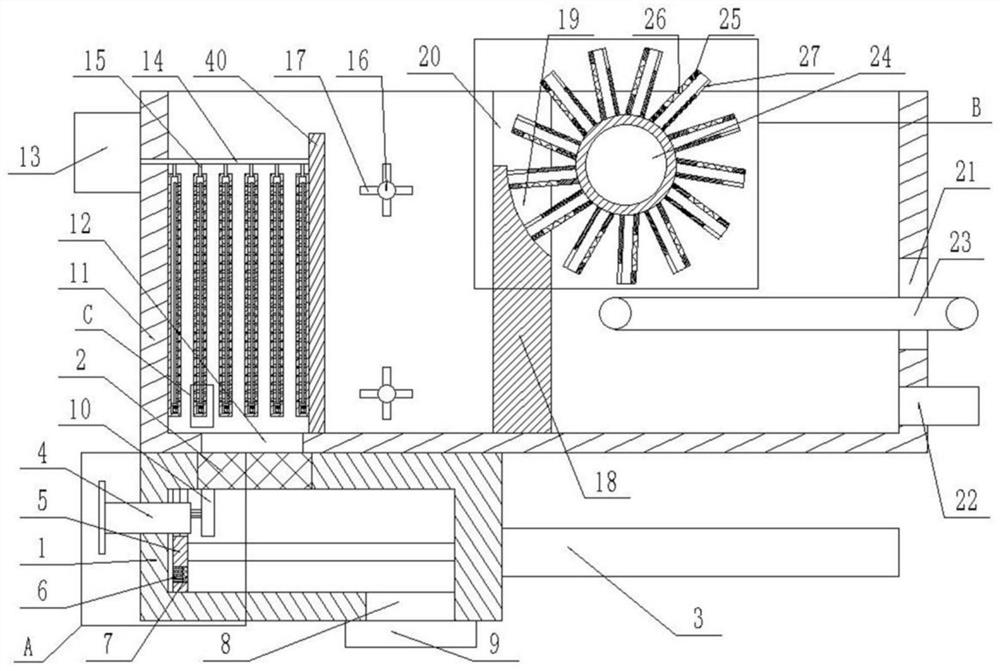

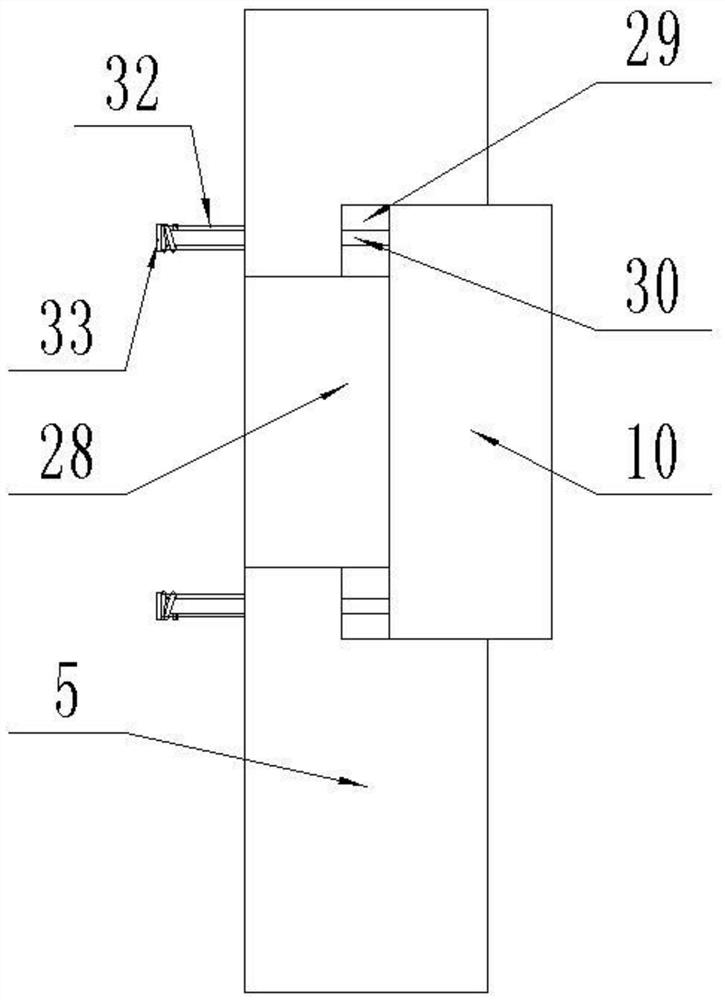

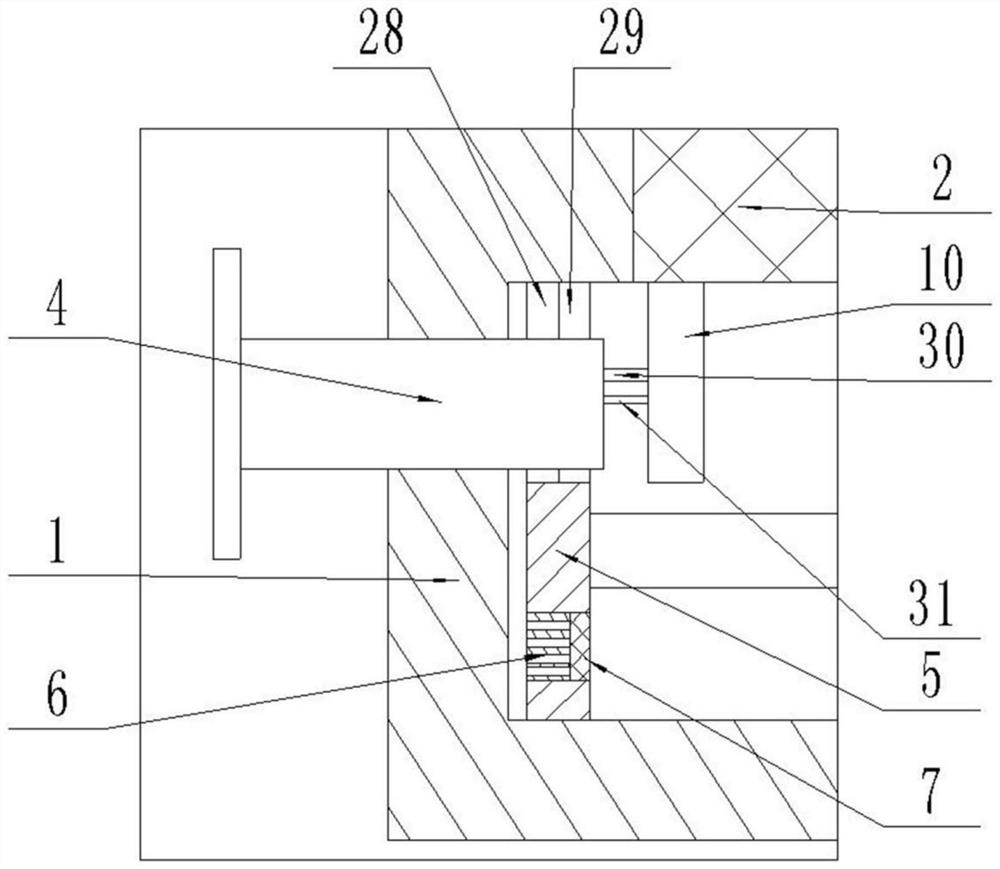

[0025] Such as Figure 1-5 As shown, an air flotation machine for down production wastewater treatment includes an air flotation treatment box 11, the lower end of the air flotation treatment box 11 is fixed with a liquid inlet box 1 communicating with it, and a solid matter extrusion discharge device is arranged in the liquid inlet box 1 , the air flotation treatment box 11 is provided with an aeration device, the air flotation treatment box 11 on the right side of the aeration device is provided with a static cavity, and a toggle device is arranged in the static cavity, and the air flotation treatment on the right side of the static cavity The box 11 is provided with a device for picking up floating objects.

[0026] The liquid inlet box 1 is fixed on the lower end of the air flotation treatment box 11, and the right side of the lower end of the liquid inlet box 1 is provided with a discharge port 8, and the lower end of the liquid inlet box 1 is detachably fixed with a seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com