Textile production wastewater treatment flocculation and cutting device

A technology for the production of waste water and turbulence devices, which is applied in the direction of grain treatment, filtration separation, separation methods, etc., can solve the problems of palliatives but not the root cause, the fiber is easy to leave from the gap, and the effect is not ideal, so as to achieve the effect of improving the degree of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

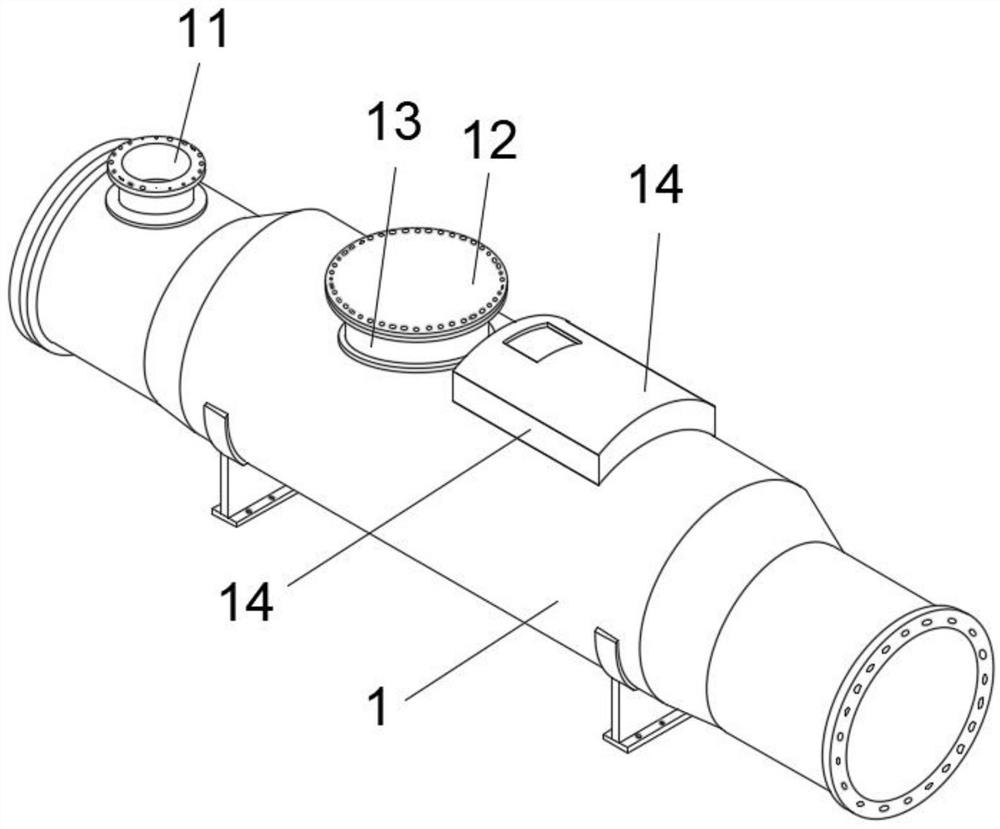

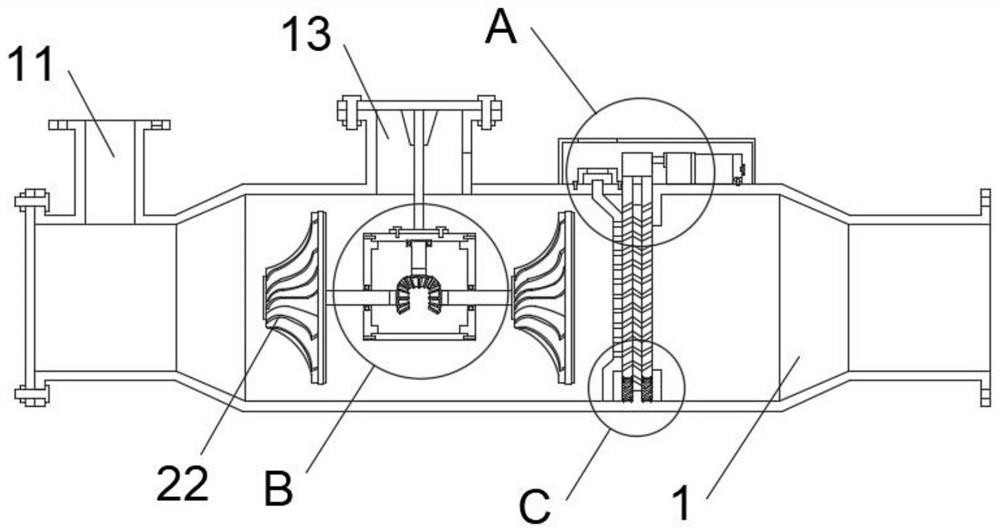

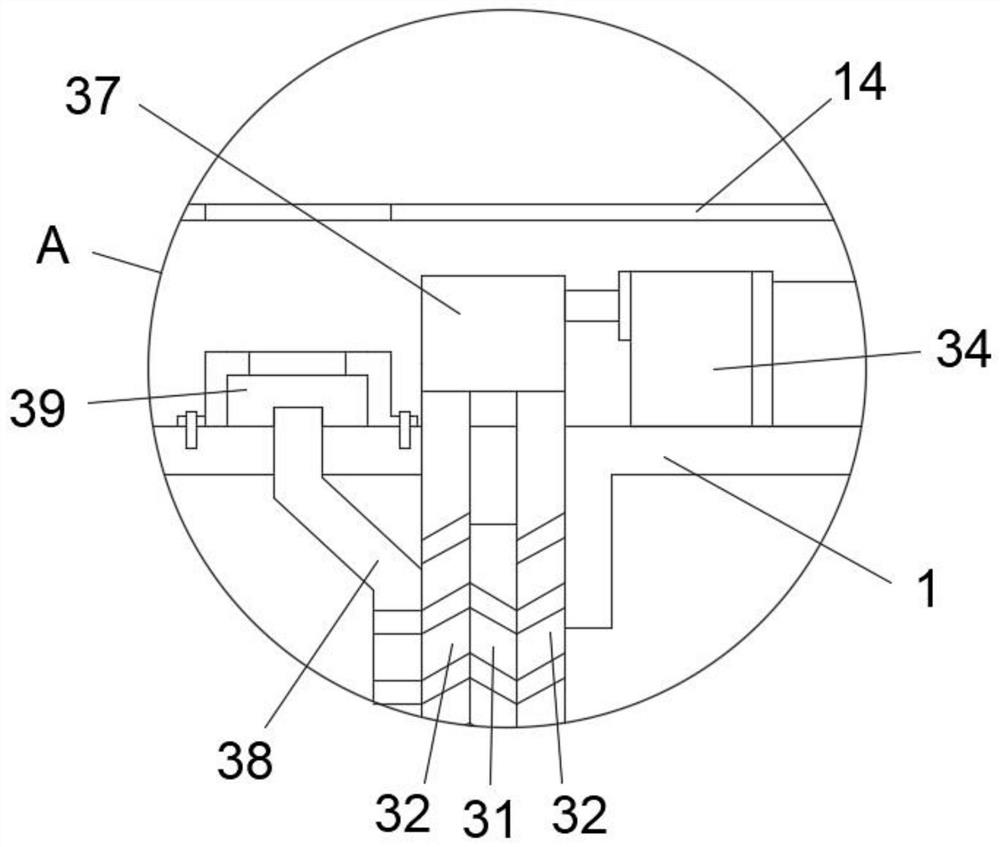

[0027] combine Figure 1-5 , a textile production wastewater treatment flocculation device, including a pipe body 1, a turbulence device and a flocculation device, the pipe body 1 is provided with a water inlet 11 on one side, and the middle part of the pipe body 1 is provided with a cover plate 12 Opening 13, the turbulence device includes an installation box 21 and fan blades 22, the installation box 21 is connected to the cover plate 12 through a connecting rod, the middle part of the installation box 21 is rotatably provided with a transmission gear 23, the installation box 21 Both sides are respectively rotatably provided with a driving gear 24 and a driven gear 25 meshing with the transmission gear 23, and the two fan blades 22 are respectively connected with the driving gear 24 and the transmission gear 23 in the same direction, and the two fan blades 22 Arranged along the length direction of the pipe body 1 and parallel to it, the flocculation cutting device includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com