An environmentally friendly Tencel solvent purification treatment device with a self-cleaning plate heat exchanger

A plate heat exchanger, purification treatment technology, applied in the direction of heat exchanger types, clean heat transfer devices, indirect heat exchangers, etc., can solve the inconvenience of waste heat recovery and reuse of textile wastewater, reduce the heat conversion efficiency of plate heat exchangers, Increase the wall thickness of the plate heat exchanger to achieve the effects of avoiding scale accumulation, buffering the flow speed, and improving heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

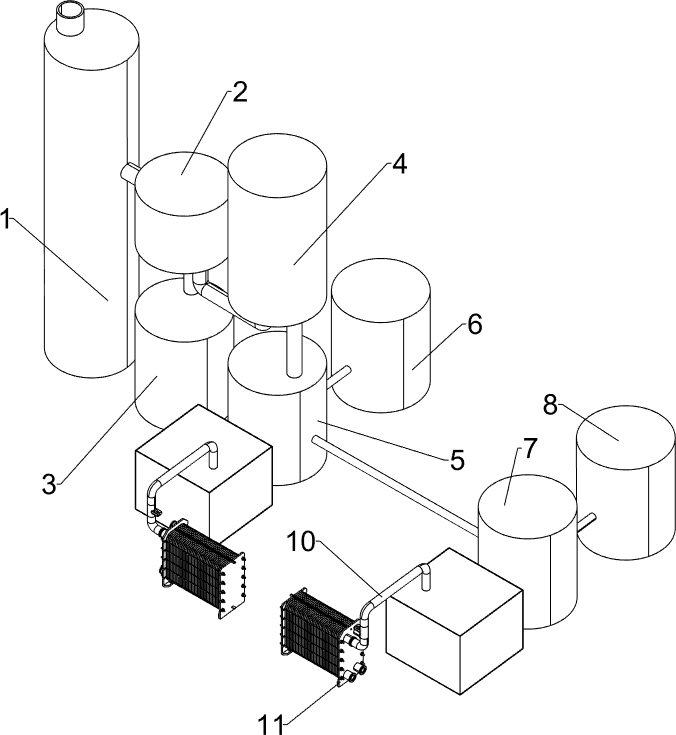

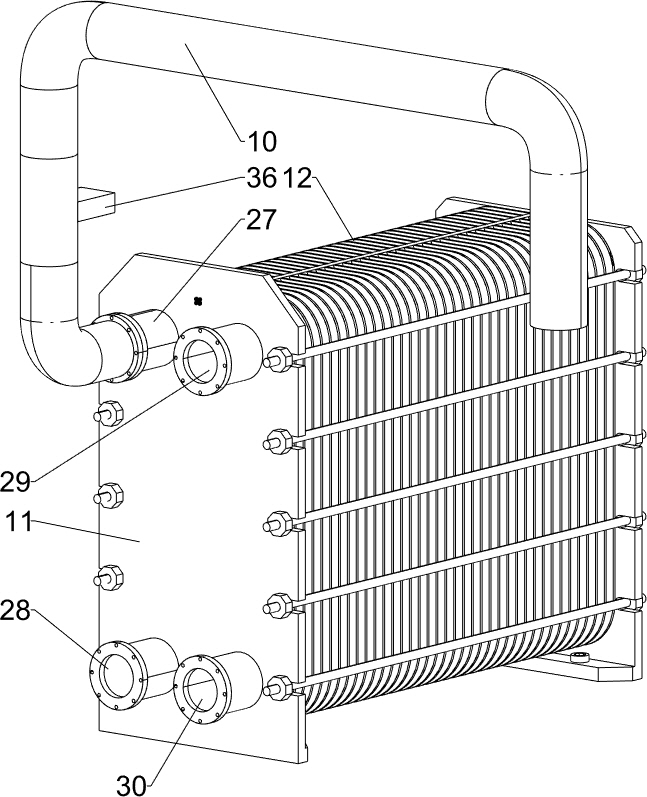

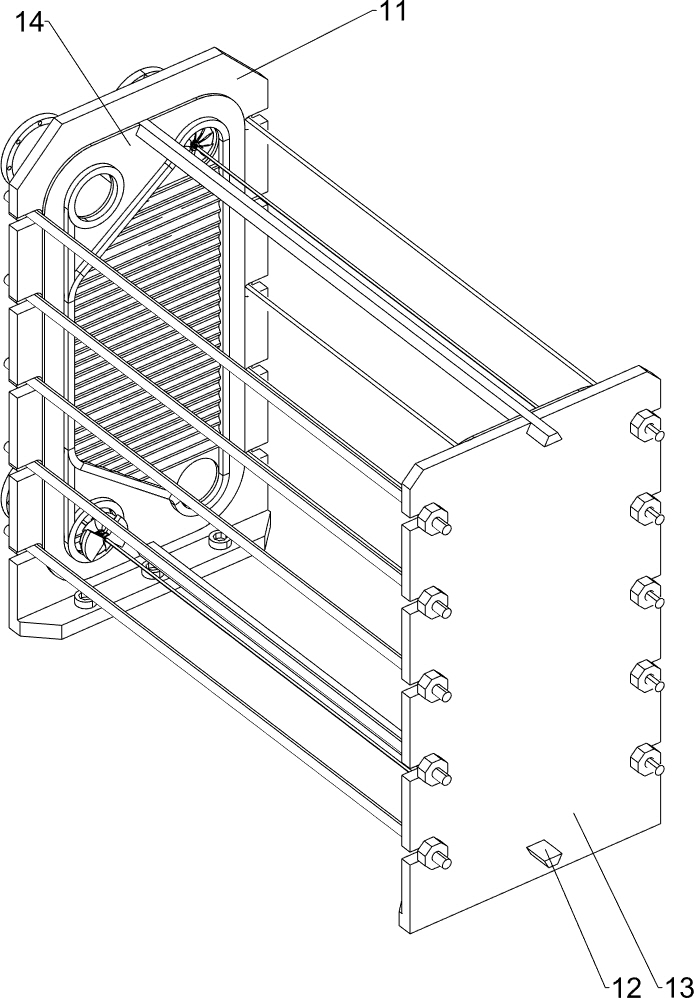

[0031] An environmentally friendly Tencel solvent purification treatment device with a self-cleaning plate heat exchanger, such as Figure 1-8As shown, it includes storage tank 1, multi-stage bed filter 2, storage tank 3, storage tank 4, double-chamber anion exchanger 5, anion bed regeneration system 6, single-chamber cation exchanger 7, cation bed regeneration system 8. The conveying pipeline 10 and the heat exchange mechanism, the right side of the storage tank 1 is provided with a multi-stage bed filter 2, the multi-stage bed filter 2 is a pumice multi-stage bed filter, and the multi-stage bed filter 2 and the material storage tank are 1 is communicated through a pipeline, a pump body is provided on the pipeline between the multi-stage bed filter 2 and the storage tank 1, a storage tank 3 is arranged below the multi-stage bed filter 2, and the storage tank 3 is connected to the multi-stage bed filter 2. Connected through pipelines, the right side of the multi-stage bed filt...

Embodiment 2

[0037] On the basis of Example 1, as Figure 9 As shown, it also includes a shunt frame 31, a rotating shaft 32 and a buffer impeller 33, and a shunt frame 31 is installed in the sewage water inlet pipe 27 and the heat exchange water inlet pipe 29, and the shunt frame 31 is used for textile waste water and cold water. A rotating shaft 32 is rotatably installed between the mounting plate 13 and the two shunt racks 31 respectively. The rotating shaft 32 on the front side is located in the through holes of the first mounting plate 11, the second mounting plate 13 and the front upper part of the partition plate 18. The rotating shaft 32 is located in the through holes in the rear lower part of the first mounting plate 11, the second mounting plate 13 and the partition plate 18. The rotating shaft 32 is equipped with a buffer impeller 33, which is used to slow down the flow rate of textile waste water and cold water, and realize the entry into the partition plate 18. The flow veloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com