Yield increasing device and method for heavy oil well

A technology for oil wells and feeding sections, which is applied to the components of pumping devices for elastic fluids, earthwork drilling, wellbore/well components, etc., and can solve problems such as high cost of use, seepage breakthrough, and small swept volume. Achieve the effects of improving flow performance, reducing crude oil fluidity, strengthening water control and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

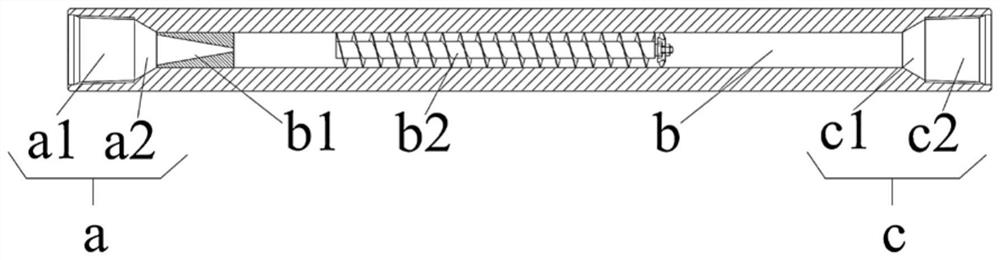

[0062] This embodiment provides a stimulation device for heavy oil wells, such as figure 1 As shown, the production increasing device includes a material inlet a, a channel b and a material outlet c arranged in sequence;

[0063] The channel b includes a transition section b1 and a helical section b2 arranged in sequence;

[0064] The transition section b1 is a first tapered structure, taking the material flow direction as a reference;

[0065] The spiral section b2 is a spiral chute structure;

[0066] The end point of the spiral chute structure is provided with an impeller, taking the material flow direction as a reference.

[0067] The lateral inclination angle of the spiral chute structure is 20°;

[0068] The pitch of the spiral chute structure is 24mm.

Embodiment 2

[0070] This embodiment provides a stimulation device for heavy oil wells, the stimulation device includes a material inlet a, a channel b, and a material outlet c arranged in sequence;

[0071] The material inlet a includes a first feed section a1 and a second feed section a2; the diameter of the first feed section a1 is 80mm; the length of the first feed section a1 is 88mm;

[0072] The second feed section a2 is a second tapered structure, with the material flow direction as a reference; the diameter of the large end of the second tapered structure is equal to the diameter of the first feed section a1; the second tapered structure The diameter of the small end of the structure is equal to the diameter of the large end of the first tapered structure; the length of the second feed section a2 is 30mm; the diameter of the small end of the second tapered structure is 40mm;

[0073] The passage b includes a transition section b1 and a helical section b2 arranged in sequence; the le...

Embodiment 3

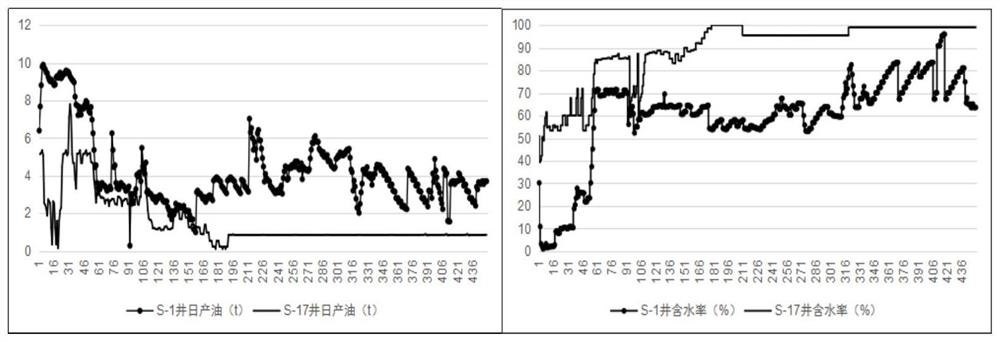

[0081] This embodiment provides a production stimulation method for heavy oil wells, which mainly consists of seven steps: wellbore hot washing, pre-construction preparation, injection process connection and pressure test, nitrogen and viscosity reducer injection, displacement injection, brine, and production.

[0082] (1) Hot washing of the operating wellbore: After backwashing, the wellbore string is lifted up to be the injection string.

[0083] (2) Construction preparation: Prepare corresponding construction equipment and materials.

[0084] (3) Injection process connection and pressure test: connect ground equipment and pipeline injection process and conduct pressure test, if the ground pressure test fails, rectification is required.

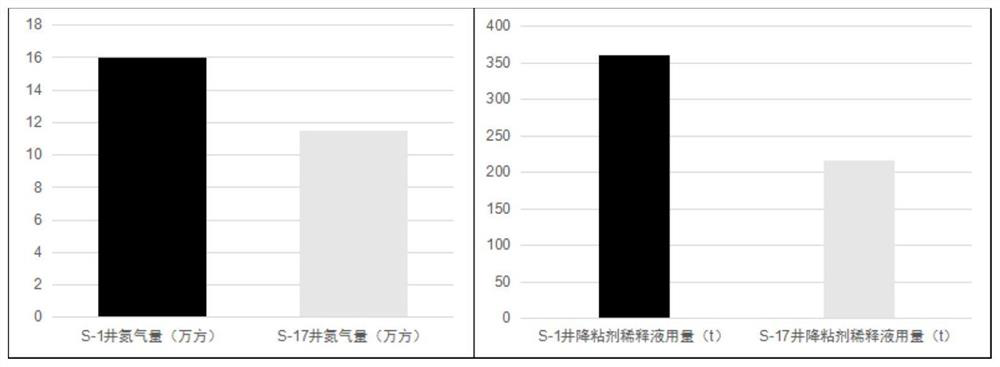

[0085] (4) Mixed injection of nitrogen and viscosity reducer: After the surface equipment and injection process pass the pressure test, start the nitrogen production nitrogen injection equipment to inject nitrogen, and the viscosity reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com