Textile wastewater recycling treatment system

A technology for recycling and textile waste water, which is applied in textile industry waste water treatment, flotation water/sewage treatment, light water/sewage treatment, etc. It can solve the problems that fibers are easy to block the filter device, difficult to discharge, and inconvenient to use. , to achieve the effect of scientific and reasonable structure, safe and convenient use, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

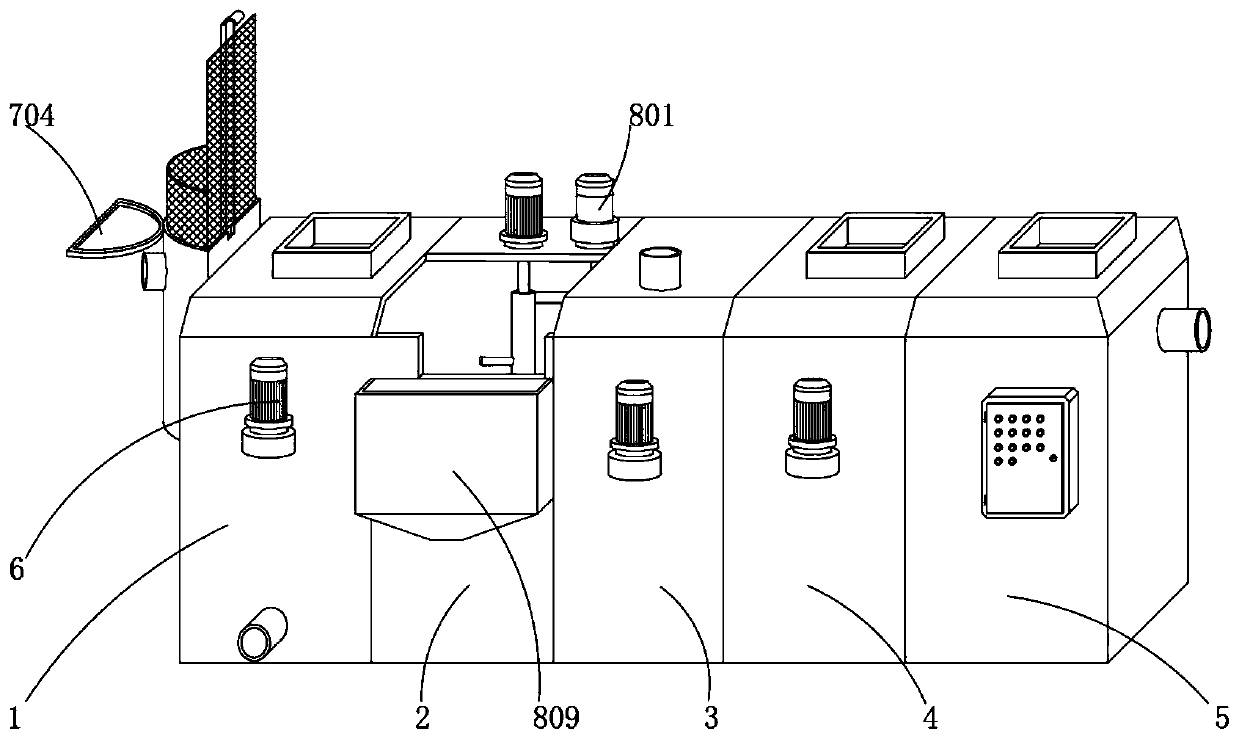

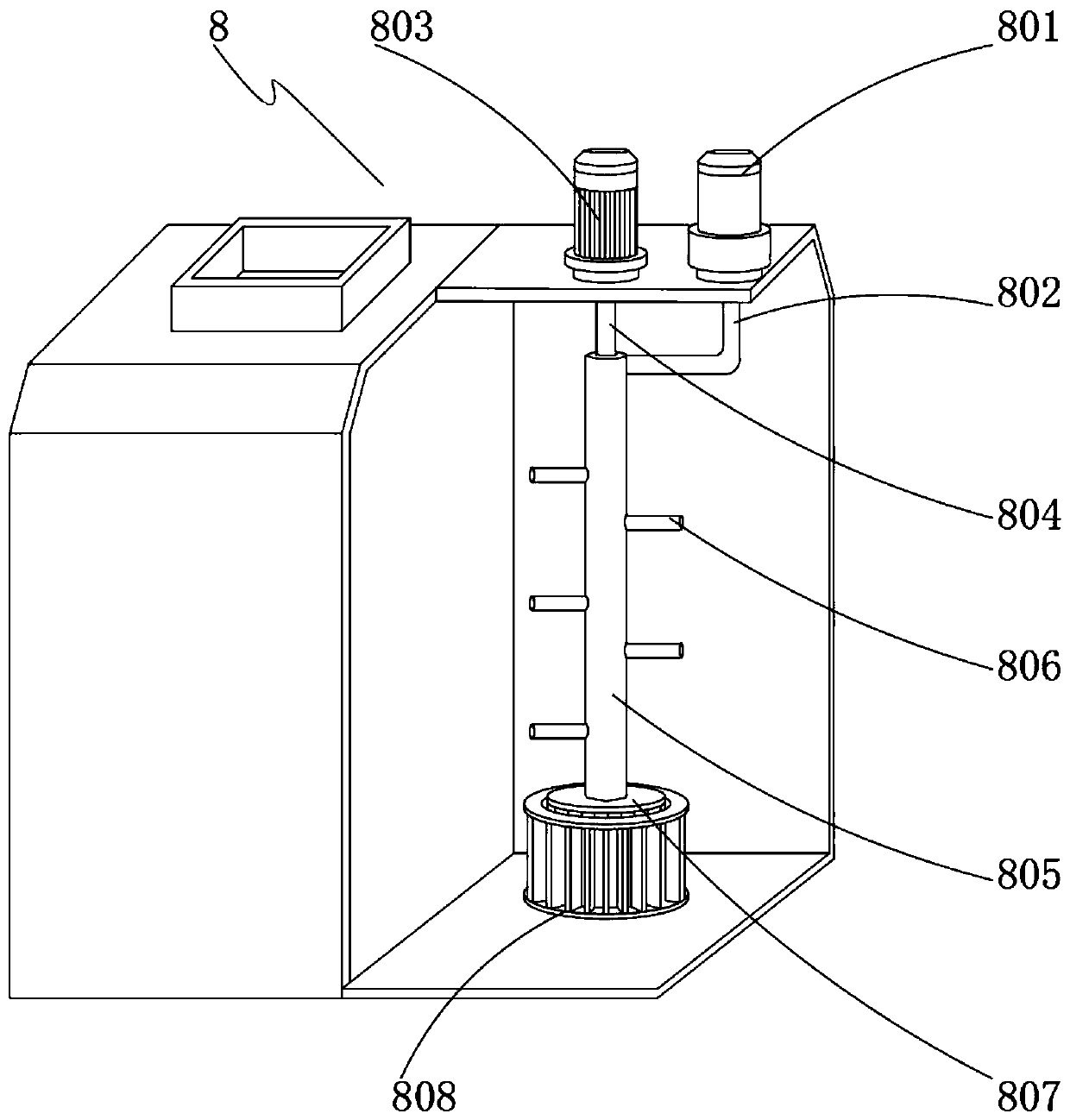

[0028] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, textile wastewater recycling treatment system, including a sedimentation tank 1, a floating removal tank 2 is fixedly installed on one side of the sedimentation tank 1, and an oxidation sterilization tank 3 is fixedly installed on one side of the floating removal tank 2 , one side of the oxidation sterilization box 3 is fixedly installed with a filter box 4, one side of the filter box 4 is fixedly installed with a clean water tank 5, the sedimentation tank 1, the float removal box 2, the oxidation sterilization box 3, the filter box 4 and the clean water tank 5 are respectively It is connected through the water pump 6, and the input end of the water pump 6 is electrically connected with the output end of the external power supply.

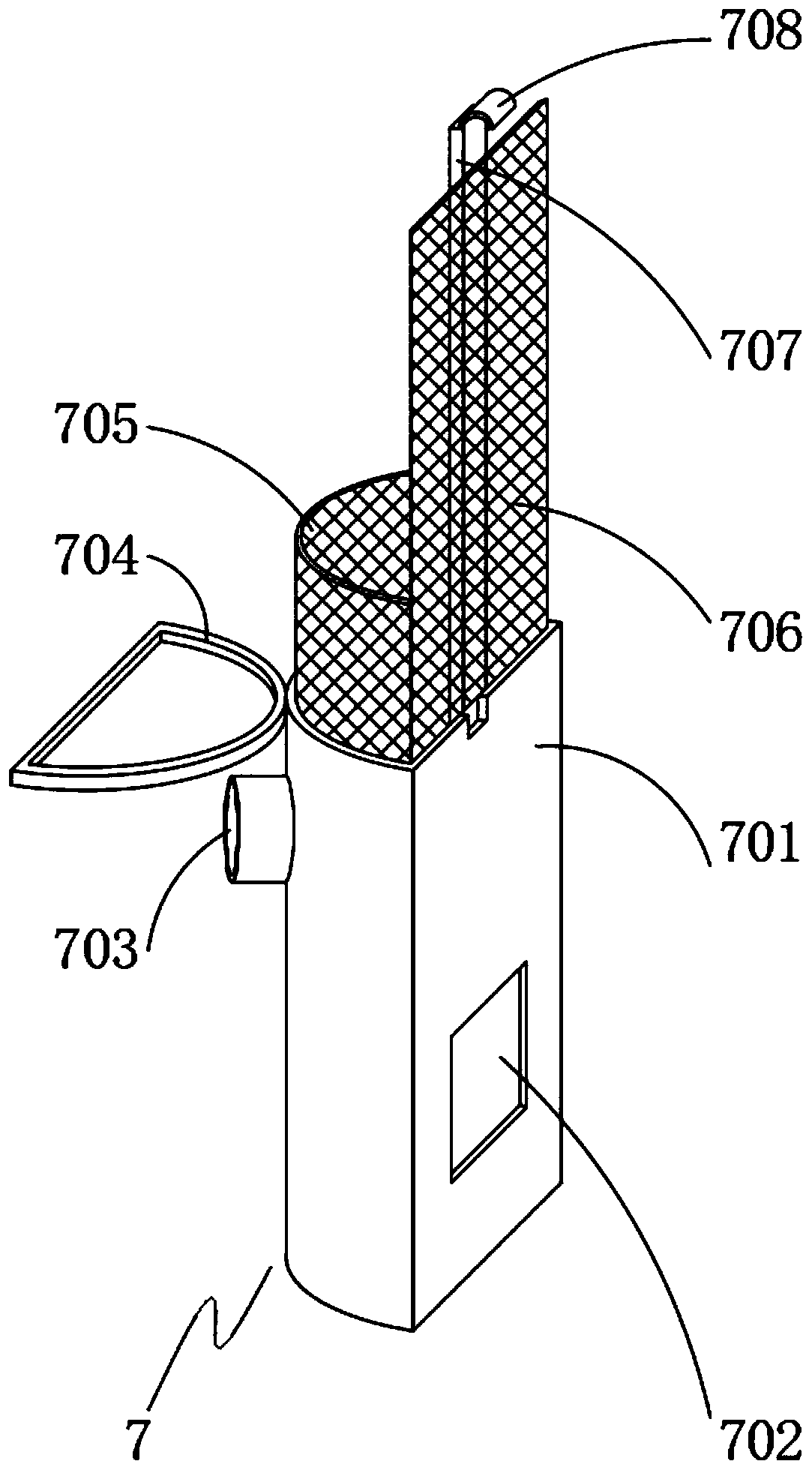

[0029] One side of the settling tank 1 is provided with a primary filter assembly 7, which includes a primary filter cartridge 701, a connection port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com