Textile wastewater interception type pretreatment equipment

A textile wastewater and pretreatment technology, applied in textile industrial wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of large water quality changes, affecting work efficiency, organic pollution of wastewater, etc., and achieve ease of filtration Effects of pressure, increased volume, and increased retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

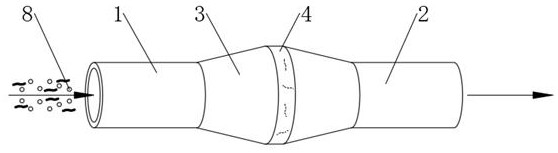

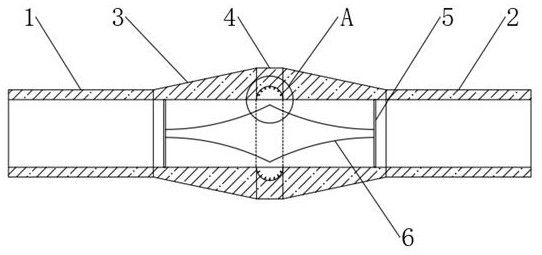

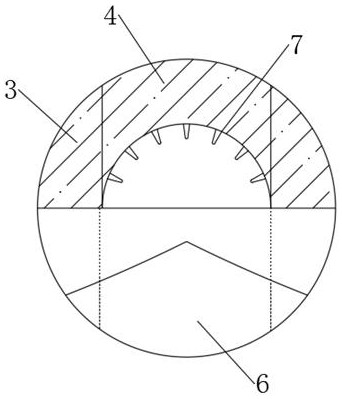

[0042] see Figure 1-3 , a kind of textile wastewater interception pretreatment equipment, including a water inlet pipe 1 and a water outlet pipe 2, the inlet pipe 1 and the water outlet pipe 2 are fixedly connected with a transition pipe 3 at one end close to each other, and a retention ring is fixedly connected between a pair of transition pipes 3 4. The inner end of the transition pipe 3 is fixedly connected with a filter screen 5, a pair of filter screens 5 is fixedly connected with a guide stem 6, and the inner end of the retaining ring 4 is provided with an annular retaining groove, which is fixedly connected with a plurality of uniform Distributed retaining magnetic columns 7, a plurality of free-moving magnetic-encapsulated balls 8 are arranged in the water inlet pipe 1.

[0043] The diameter of the guide stem 6 gradually increases along the position close to the retaining ring 4, and its cross-sectional edge lines are mutually symmetrical concave arcs, which can effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com