Wall-attached undulating textile effluent fiber intercepting and crushing device

A technology of textile wastewater and wall undulation type, which is applied in the direction of textile industrial wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problem of large water quality changes, large water volume, and difficulty in achieving high discharge by wastewater treatment facilities Standards and other issues, to achieve good results and reduce the effect of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

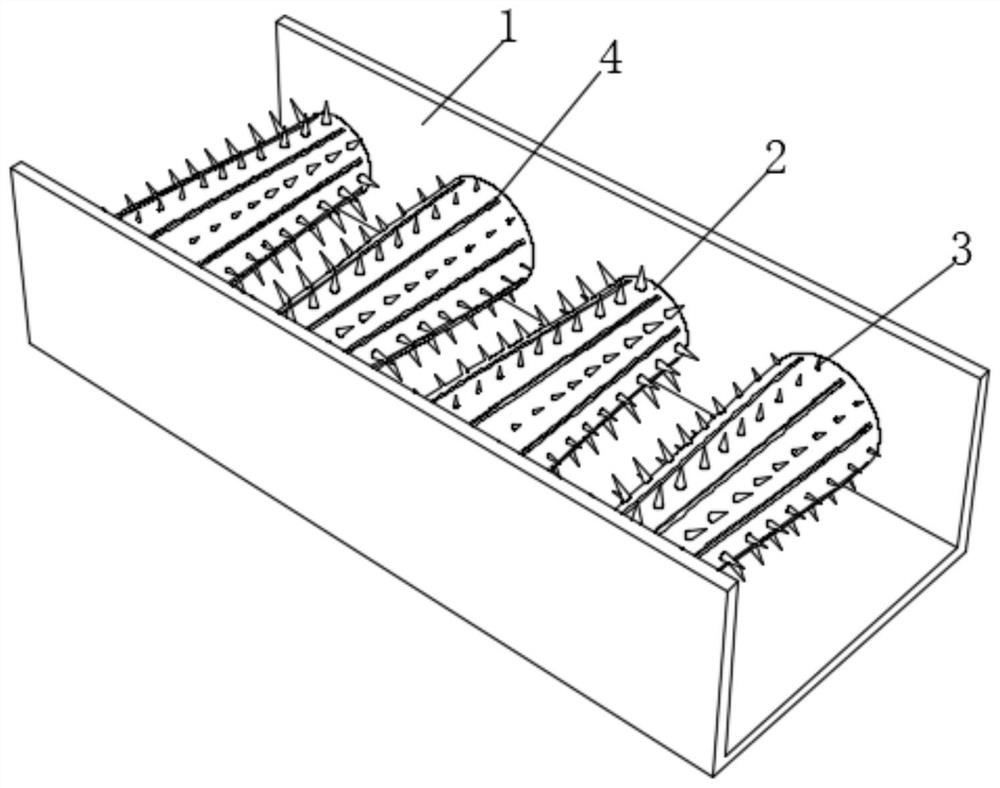

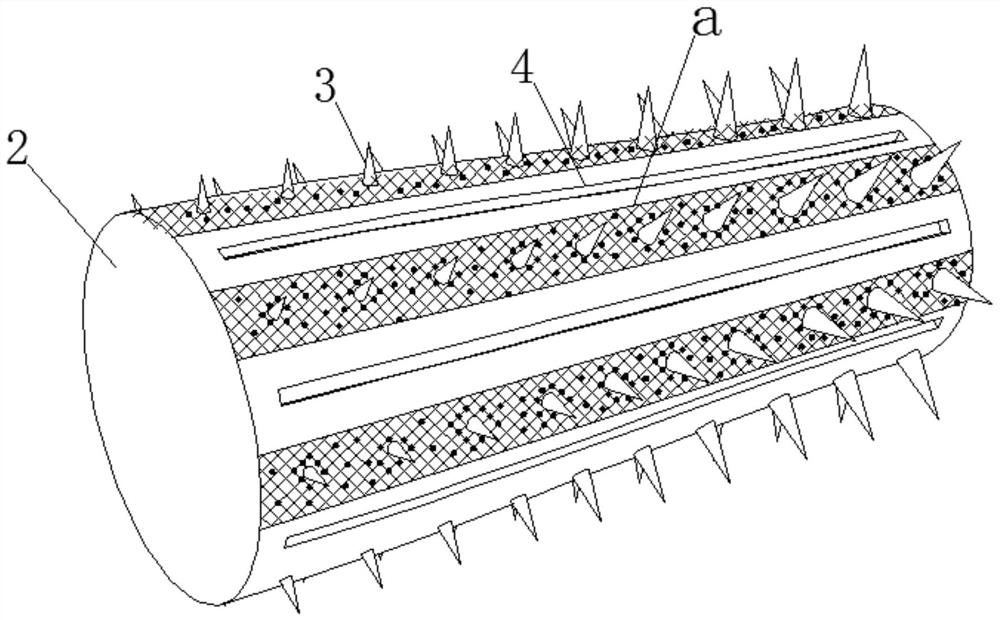

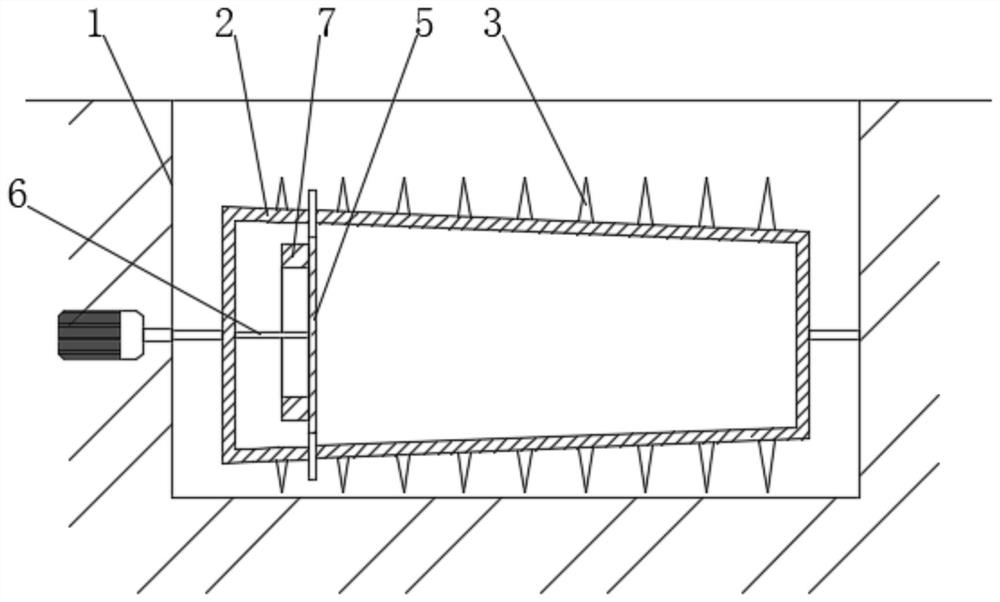

[0043] see Figure 1-2 , a in the figure represents a wall-adhesive loosening aid, which represents a wall-adhesive undulating textile wastewater fiber interception and crushing device, including a plurality of evenly distributed uneven crushing cylinders 2 installed in the cleaning tank 1, and a plurality of uneven crushing cylinders 2 The head and the tail are staggered with each other, and a plurality of uniformly distributed transverse crushing grooves 4 are excavated on the surface of the uneven crushing cylinder 2. A group of winding thorns 3 is arranged between each adjacent two transverse crushing grooves 4, and each group of winding thorns 3 The outer ends are equipped with wall-adhering loosening aids, and the peripheral edges of the wall-adhering loosening aids are fixedly connected with the uneven crushing cylinder 2;

[0044] The wall-adhering loose film includes an elastic diaphragm and multiple magnetic points embedded in the elastic diaphragm. When the undulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com