Textile wastewater treatment system<0}

A technology of textile wastewater and treatment system, which is applied in the direction of textile industrial wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., which can solve the problem of difficult discharge or reuse of wastewater, complex and cumbersome process flow, and unfavorable biological bacteria. The problem of seed growth and other problems can be solved, and the effect of good decolorization effect, stable system operation and high degree of automation can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

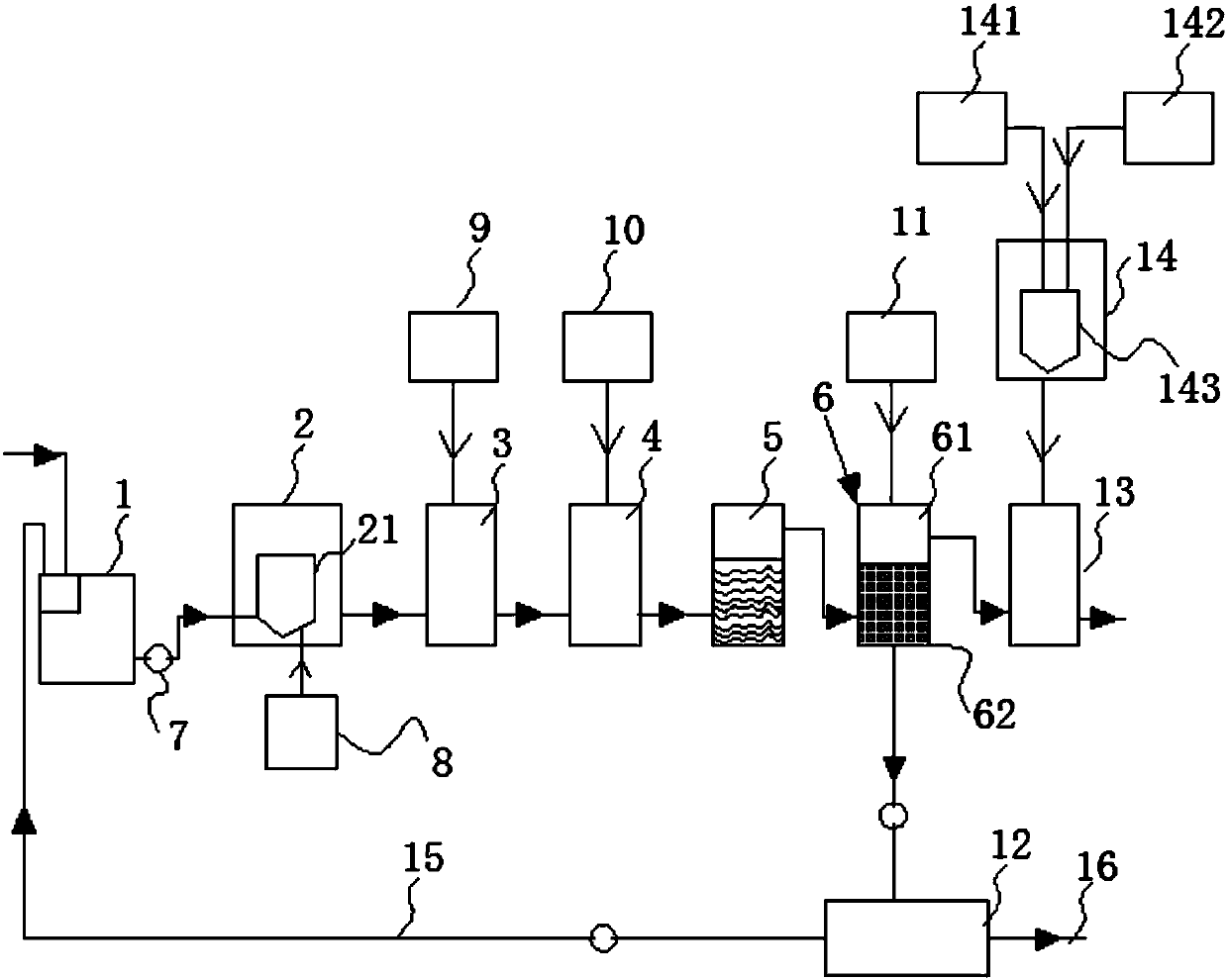

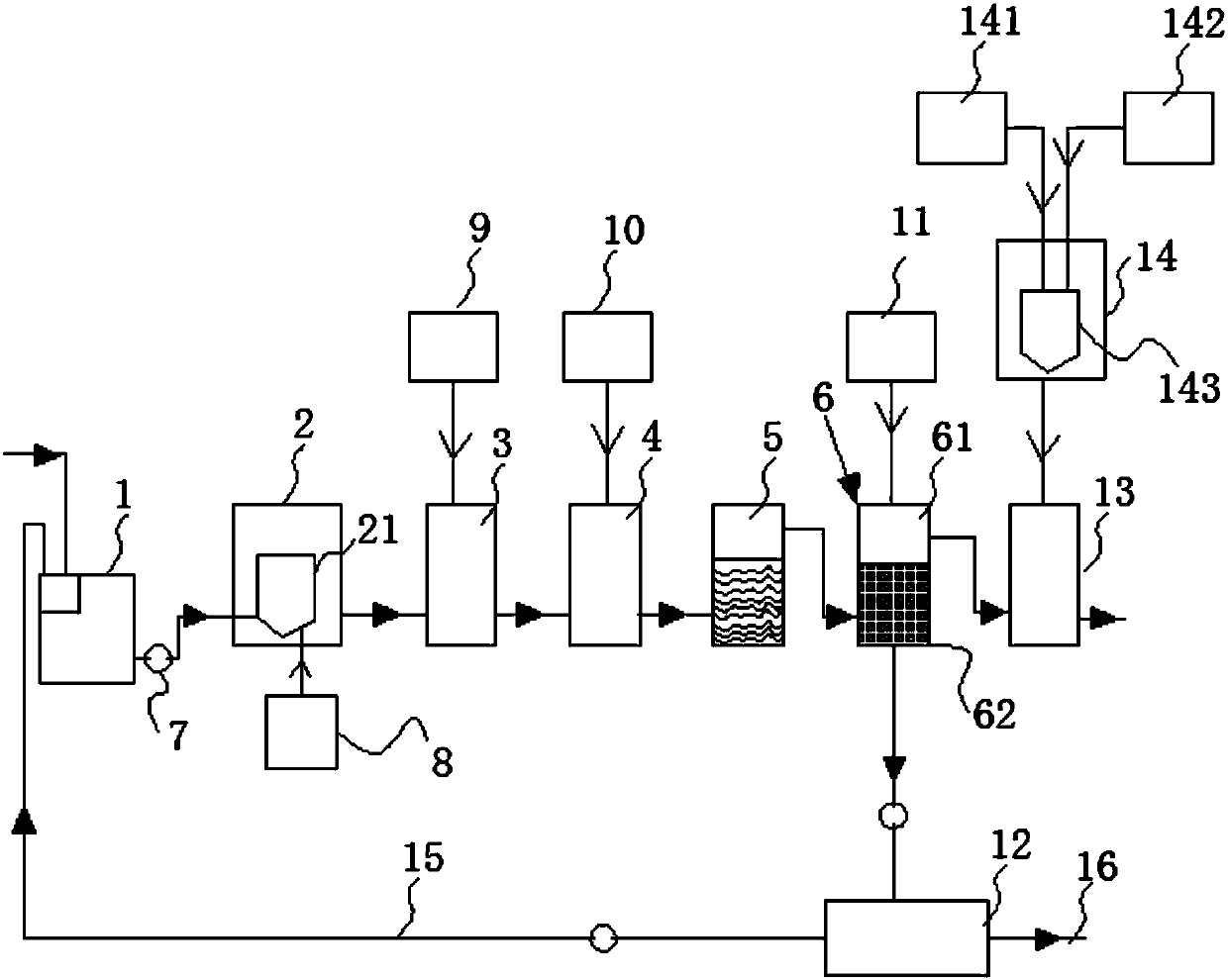

[0033] Embodiment: a kind of textile wastewater treatment system, such as figure 1 As shown, it includes a grid grease trap 1 that can collect textile wastewater, and a decolorization pretreatment tank 2, a conditioning tank 3, a hydrolysis acidification tank 4, a contact oxidation Pool 5 and reaction sedimentation tank 6;

[0034] A water pump 7 is provided on the wastewater pipeline 15 between the grid grease trap 1 and the decolorization pretreatment pool 2, and a central reaction barrel 21 is arranged in the decolorization pretreatment pool 2, and the decolorization pretreatment pool 2 The periphery is provided with a decolorizing agent feeding device 8, and both the decolorizing agent and waste water enter from the bottom of the central reaction tank;

[0035] The periphery of the regulating pool 3 is provided with an acid-base feeding device 9, and the acid-base feeding device 9 communicates with the regulating pool 3, and the periphery of the hydrolytic acidification p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com