Fluff fiber treatment method for pneumatic desorption type textile wastewater

A technology for textile wastewater and fiber treatment, which is applied in textile industrial wastewater treatment, adsorption water/sewage treatment, water treatment parameter control, etc. The problem of high concentration of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

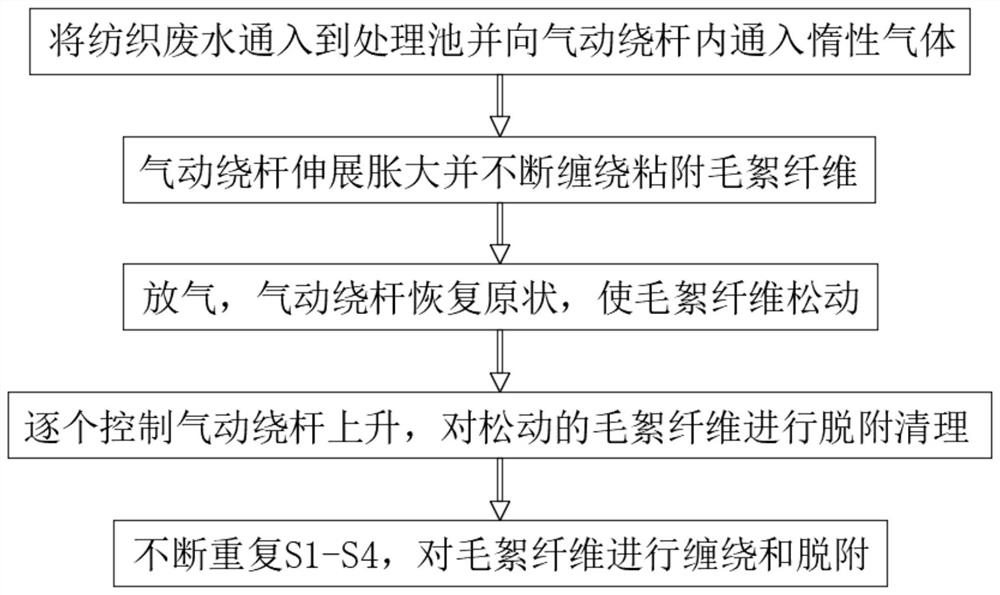

[0045] See figure 1 , A method for treating fluff fibers of pneumatic desorption textile wastewater, including the following steps:

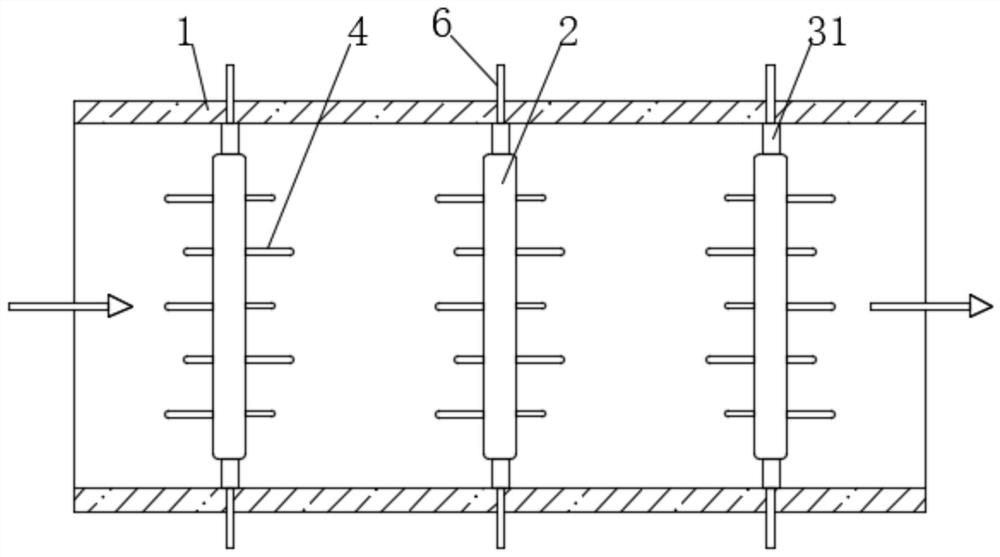

[0046] S1. First, pass the textile wastewater into the treatment tank 1, and at the same time pass inert gas into the pneumatic winding rod in the treatment tank 1;

[0047] S2. After the inside of the pneumatic winding rod is inflated, it gradually expands and swells. The textile waste water continuously passes through the pneumatic winding rod, and the wool fibers in the textile waste water are continuously wound and adhered by the stretched and expanded pneumatic winding rod;

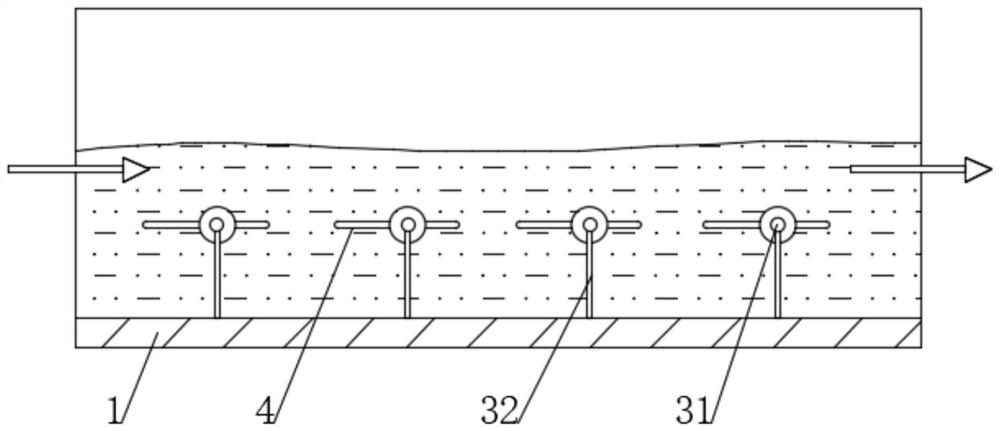

[0048] S3. When the woolen fiber with a lot of adhesion is wound on the pneumatic winding rod, the inert gas is released to make the pneumatic winding rod return to its original state. At this time, the wool fiber on the pneumatic winding rod surface becomes loose and is connected with the pneumatic winding rod. There is a large gap between;

[0049] S4. At this time, the pneu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com