Floating type textile wastewater flocculent fiber recovery device

A textile wastewater and fiber recycling technology, which is applied in textile industrial wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve problems such as easy blockage, surrounding soil hazards, and increased difficulty in textile wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

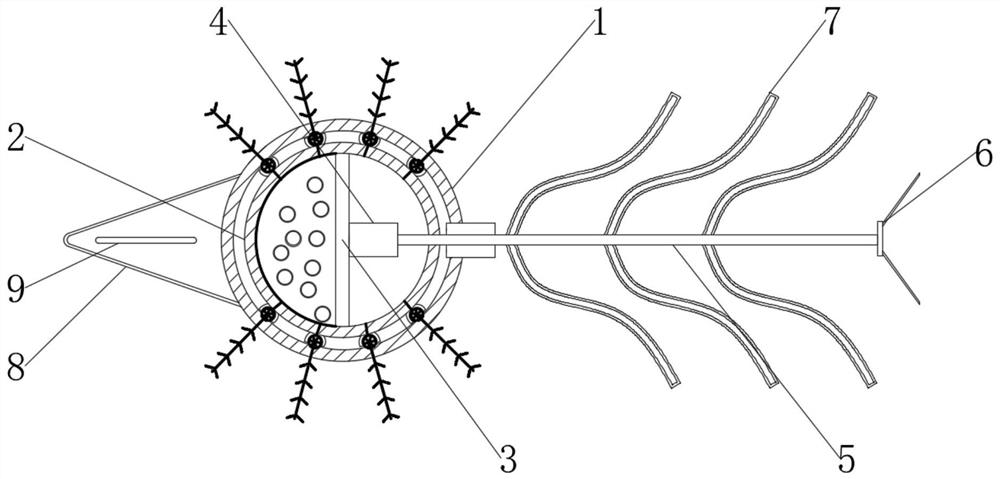

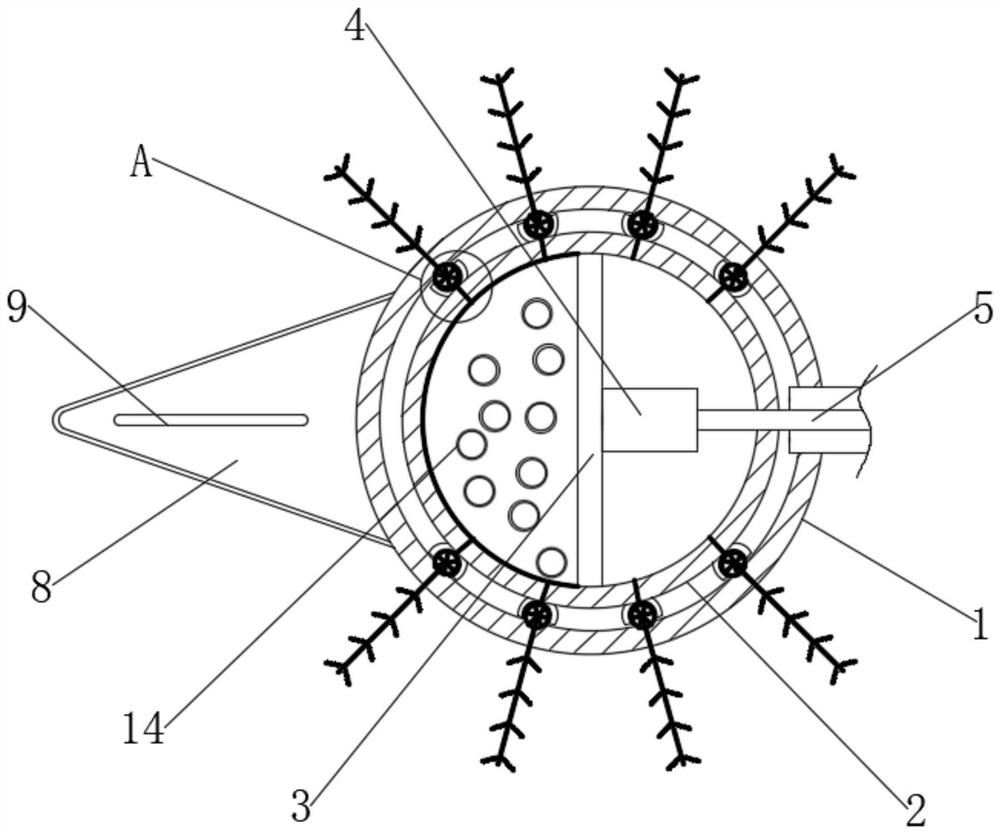

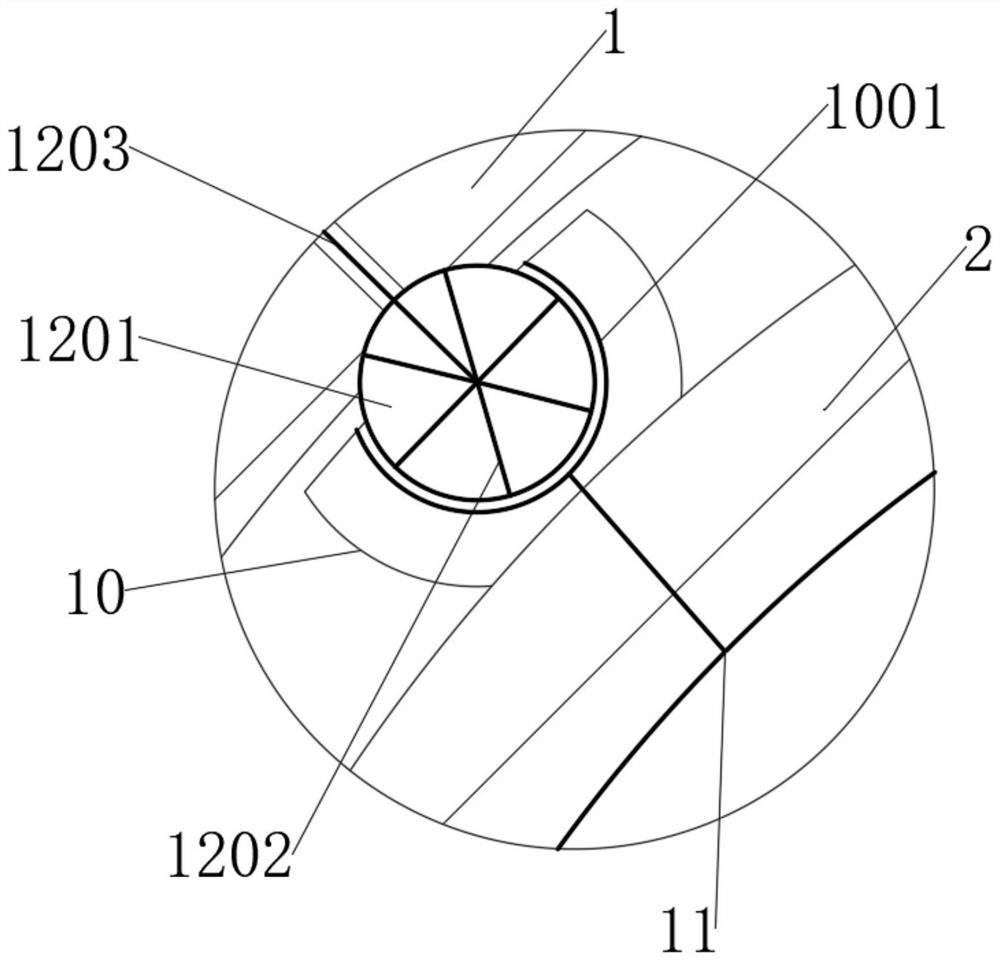

Embodiment 1

[0042] see Figure 1-2 , a floating textile wastewater floc fiber recovery device, comprising a wastewater treatment bin 15 and a plurality of hollow main balls 1, the plurality of hollow main balls 1 are placed in the waste water treatment bin 15, and a hollow rotating shaft is arranged in the hollow main ball 1 Ball 2, the center of the inner wall of the hollow rotating ball 2 is fixedly connected with a partition plate 3, the right end of the partition plate 3 is fixedly connected with a power distribution motor 4, and a small power supply is installed in the power distribution motor 4 to provide power, and the output end of the power distribution motor 4 is fixedly connected There is a rotating shaft 5 that runs through the hollow rotating ball 2, and the outer end of the rotating shaft 5 is fixedly connected with the hollow main body ball 1 through a fixing ring. Relative movement occurs, thereby generating relative friction. The right end of the rotating shaft 5 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com