Hot laminating machine and hot laminating method

A laminating machine and heat laminating technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of manual participation, low operation efficiency, and leather products are easy to get dirty, so as to reduce the chance of contamination and improve The effect of the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a thermal bonding machine for processing decorative parts of electronic products, which has high processing efficiency, requires fewer workers, and reduces the probability of contamination of the first material or the second material. Exemplarily, the decorative part in this embodiment may be a leather layer, etc., which is not limited in this embodiment.

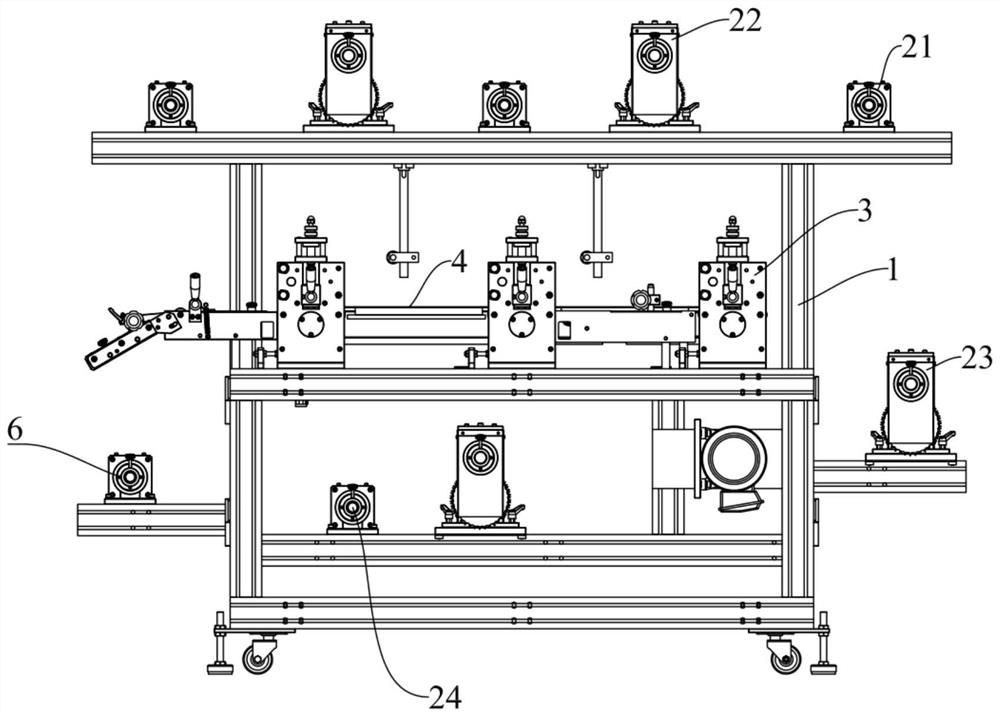

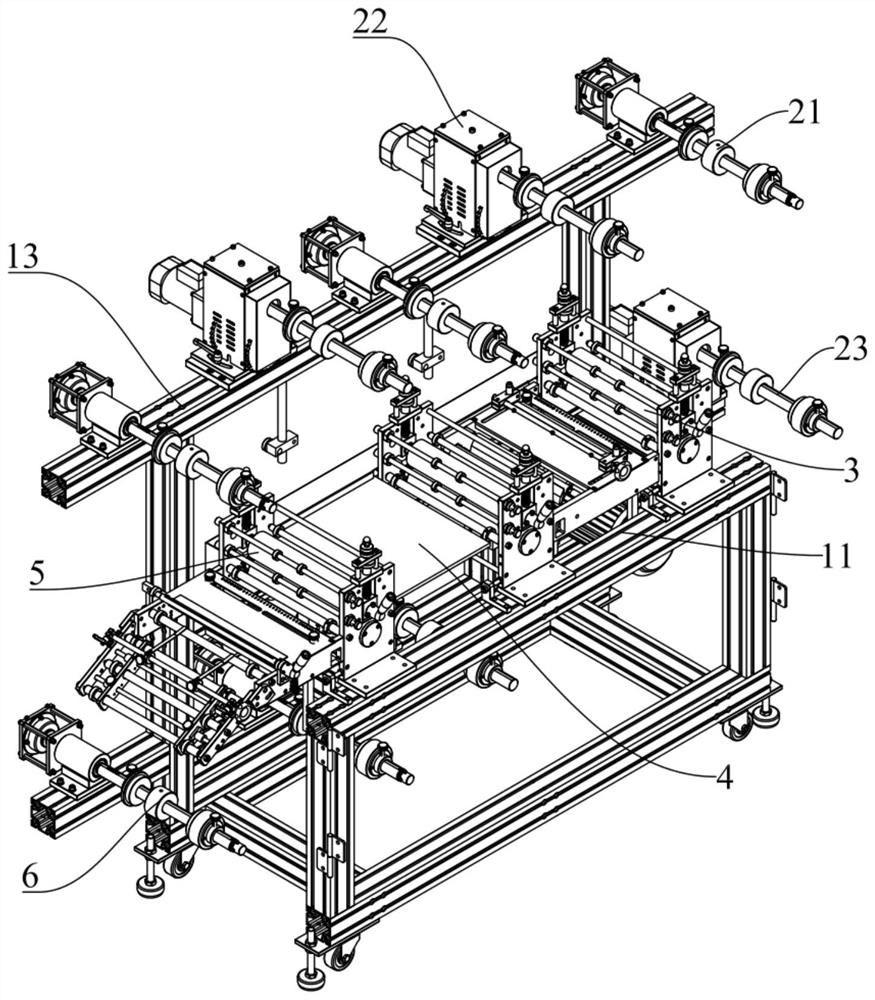

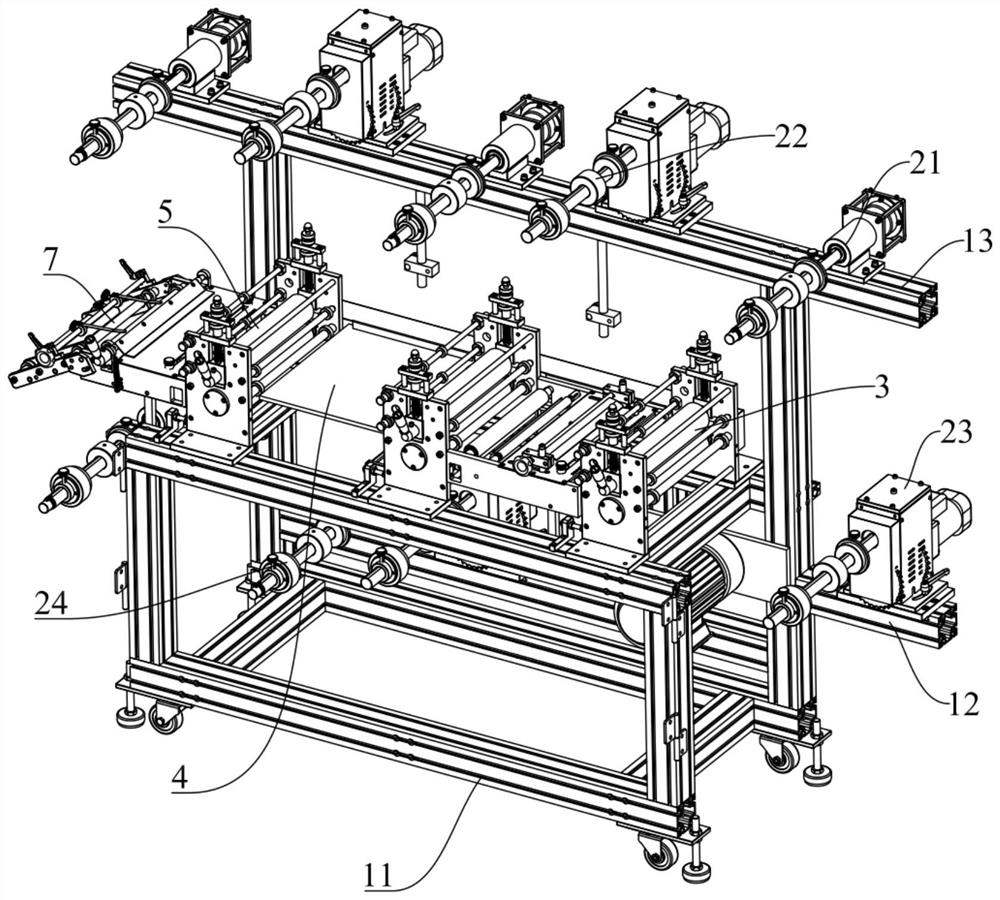

[0042] Such as figure 1 As shown, the heat laminating machine includes a support assembly 1, and a retractable and unwinding assembly, a flattening assembly 3 and a heating assembly 4 respectively arranged on the support assembly 1 .

[0043] Among them, see figure 1, The receiving and discharging assembly includes a first discharging member 21 , a first receiving member 22 and a second discharging member 23 respectively arranged on the support assembly 1 . The first discharging member 21 is used for discharging the first material, so that the first material can be discharged continuously. ...

Embodiment 2

[0059] This embodiment provides a thermal lamination method, which is applied to the thermal lamination machine in Embodiment 1, and has the advantages of high efficiency and fewer required workers.

[0060] Such as Figure 5 As shown, the heat bonding method includes the following steps:

[0061] S1. Hang the roll-shaped first material on the first discharge member, and the first protective film is attached to the first material.

[0062] In this embodiment, hanging the roll-shaped first material on the first discharge member 21 is specifically setting the roll-shaped first material on the first rotating shaft of the first discharge member 21 .

[0063] S2. Hang the rolled second material on the second discharging member.

[0064] In this embodiment, hanging the roll-shaped second material on the second discharge member 23 is specifically setting the roll-shaped second material on the third rotating shaft of the second discharge member 23 .

[0065]S3. Pull the first mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com