Patents

Literature

50results about How to "Realize continuous discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

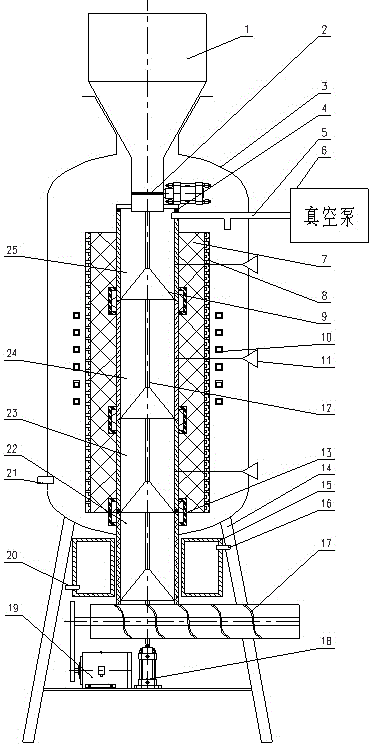

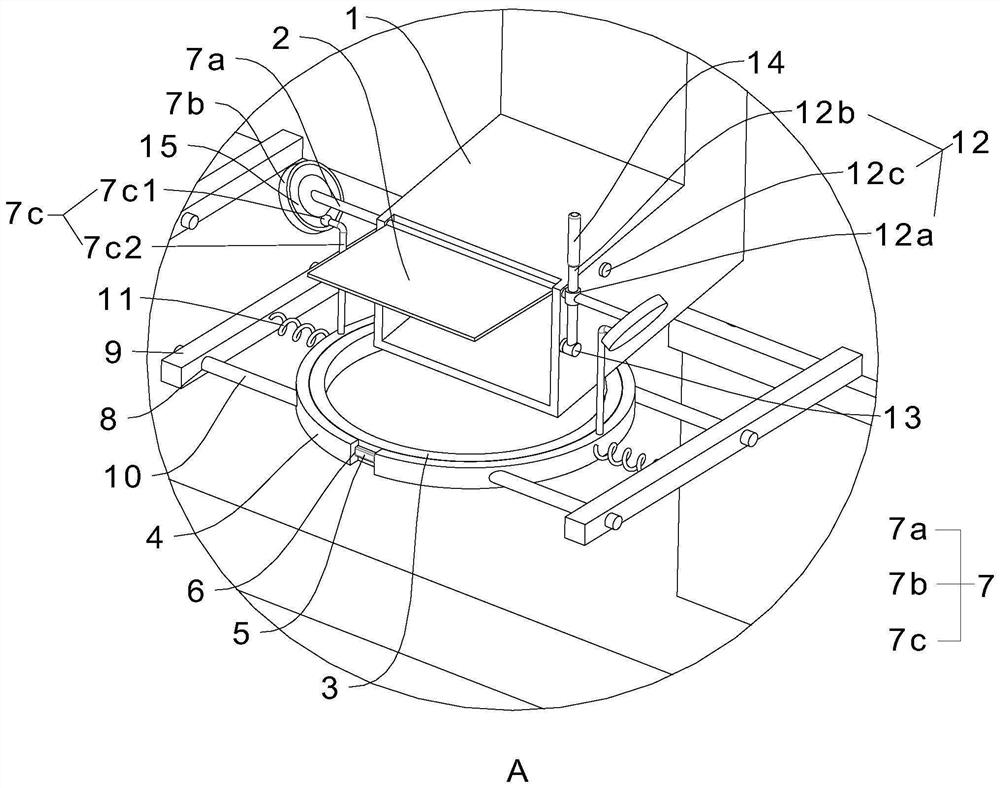

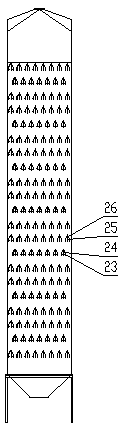

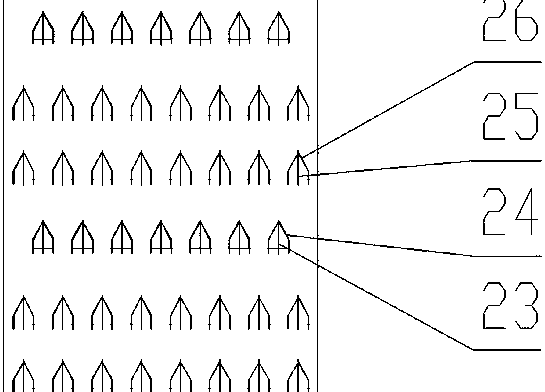

Vertical continuous induction type high-temperature graphitization furnace

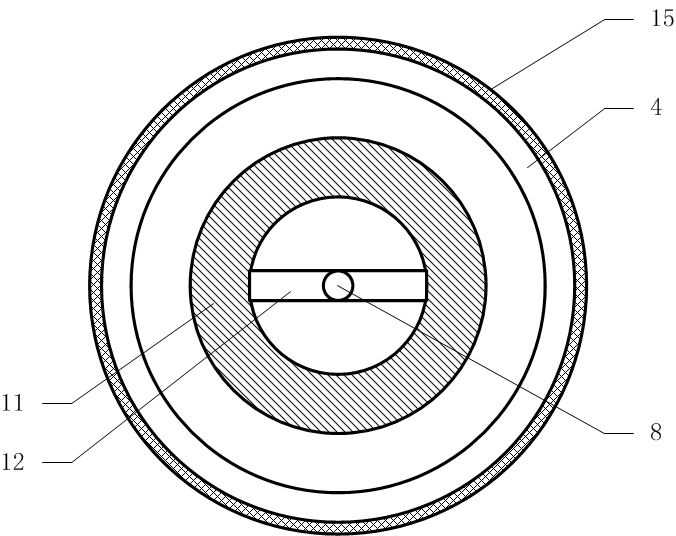

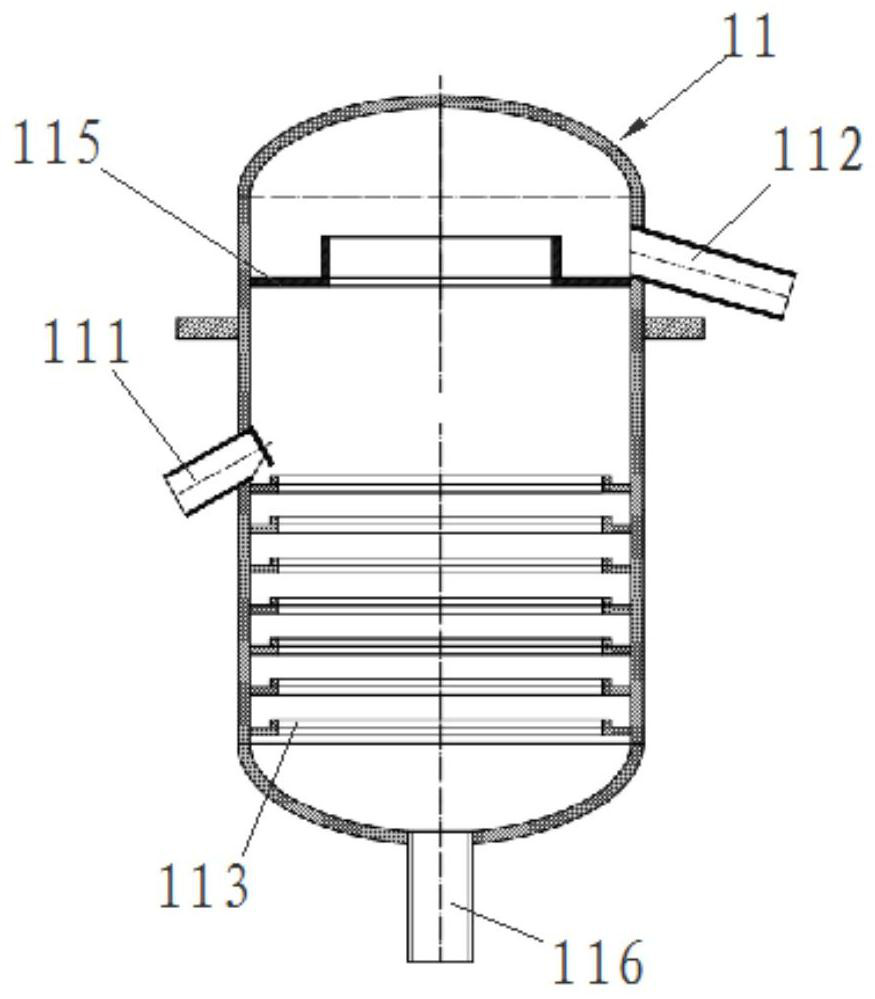

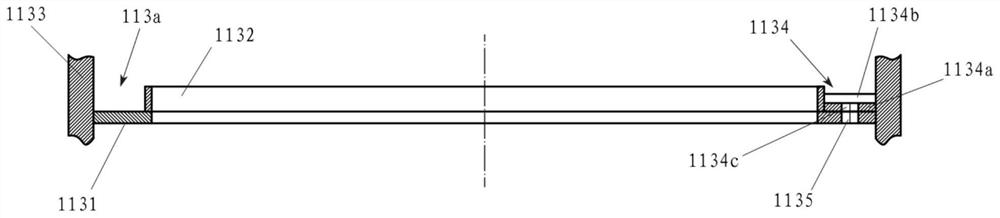

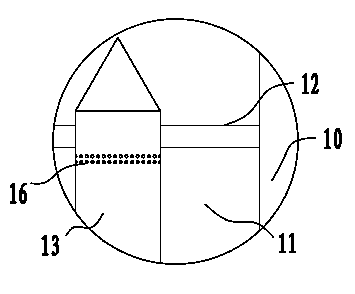

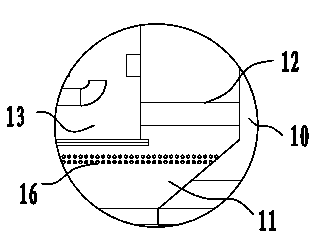

The invention discloses a vertical continuous induction type high-temperature graphitization furnace. The graphitization furnace comprises a furnace body shell, a hopper positioned above the furnace body shell, and a discharging pipe positioned at the bottom of the furnace body shell, wherein the hearth inside the furnace body shell is divided into four areas from top to bottom, namely a preheating area, a heating area, a temperature reducing area and a cooling area; every two adjacent areas are communicated with each other or isolated from each other by a corresponding isolating material part having an opening and closing function; a discharging port of the hopper is connected with a feeding hole of the preheating area by a valve; a heat insulating layer is arranged in the peripheral direction of the outer wall of the hearth; a heater is arranged between the inner wall of the shell and the heat insulating layer segment outside the heating area; a cooling system is arranged outside the discharging pipe so that the cooling area is formed inside the discharging pipe. The graphitization furnace disclosed by the invention has the advantages of greatly increasing the yield and quality of a graphitized material, satisfying the technological requirements of thermal treatment of a cathode material of a power battery and improving the quality of the battery.

Owner:湖南烁科热工智能装备有限公司

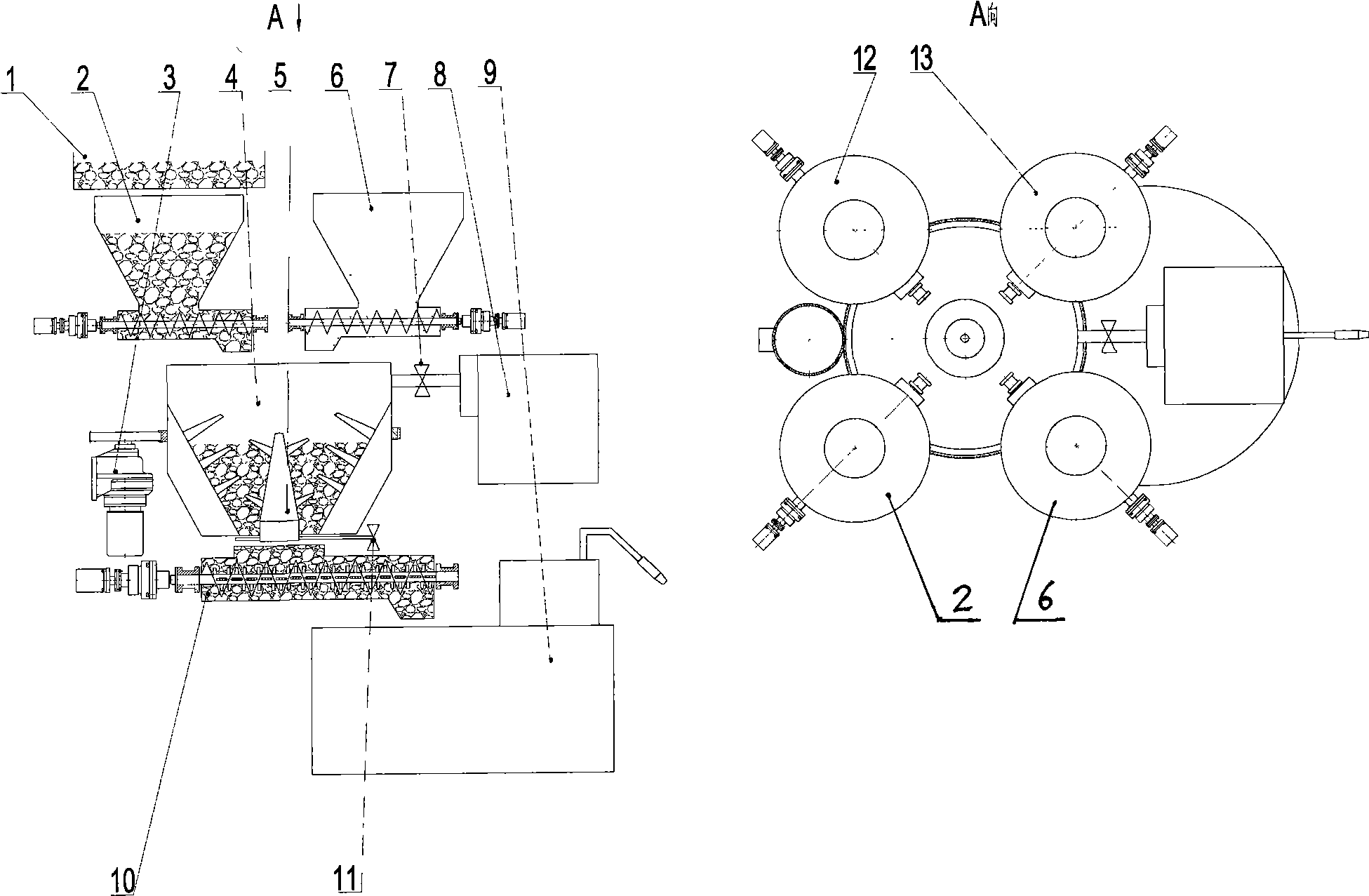

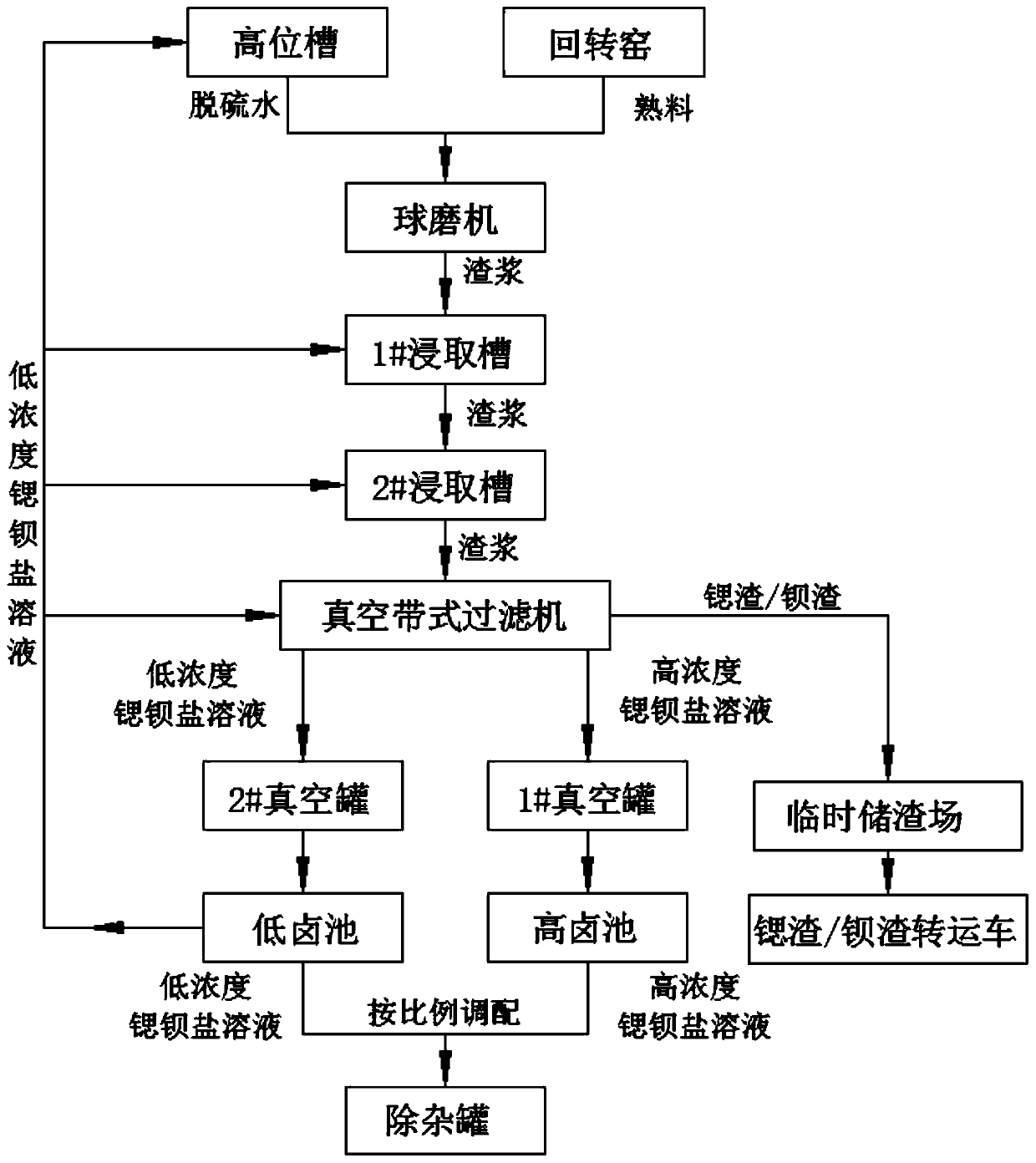

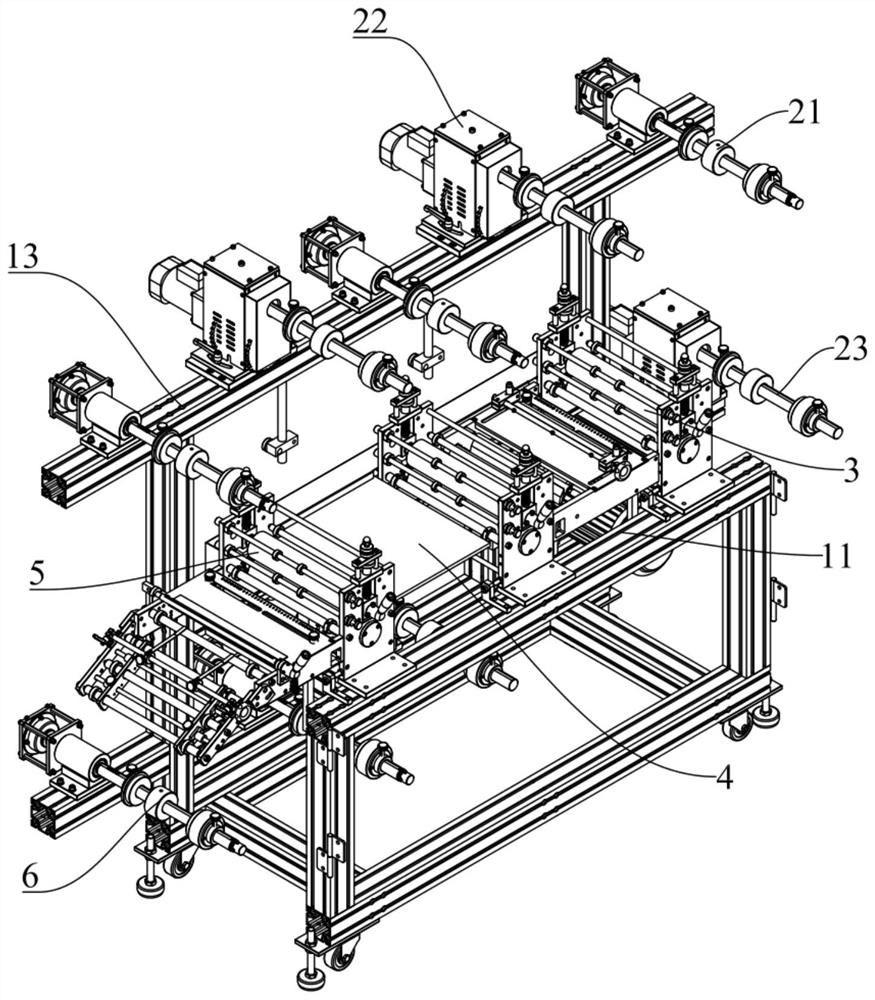

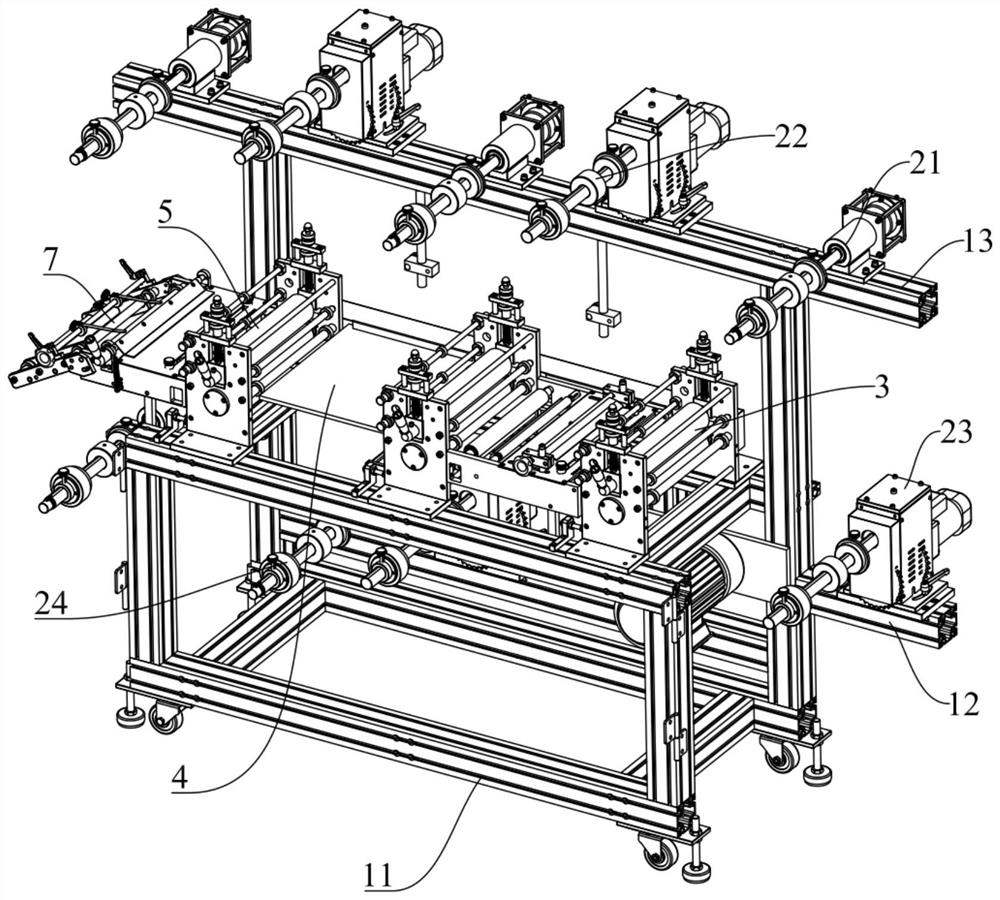

Concrete continuous stirring and conveying system device

InactiveCN101497218ARealize the mechanization of stirringFully automatedMixing operation control apparatusCement mixing apparatusSolid componentEngineering

The invention relates to a concrete continuous mixing and conveying system device, which comprises a stone screen (1), a stone measuring and conveying system (2), a concrete mixing cylinder driving motor (3), a concrete mixing cylinder (4), a concrete fixed mixer (5), a sand measuring and conveying system (6), a water feed regulating valve (7), a water tank and a pumping system (8), a concrete storage tank and a pumping system (9), a concrete secondary mixing and conveying system (10), a concrete discharge regulating valve (11), a cement measuring and conveying system (12), an additive measuring and conveying system (13), and the like; the feed mode of concrete solid components adopts a screw rod continuous pumping mode, and the concrete is fully and intensely mixed at one time after the concrete enters the concrete mixing cylinder (4) of which the inner wall is provided with compulsory mixing blades; and the mixed concrete is put into the concrete secondary mixing and conveying system (10) through the concrete discharge regulating valve (11) for the second mixing and then pumped into the concrete storage tank (9). The whole system can maintain the required concrete mixture ratio through control, can continuously mix and discharge the concrete, and has high production efficiency.

Owner:邓嘉鸣 +2

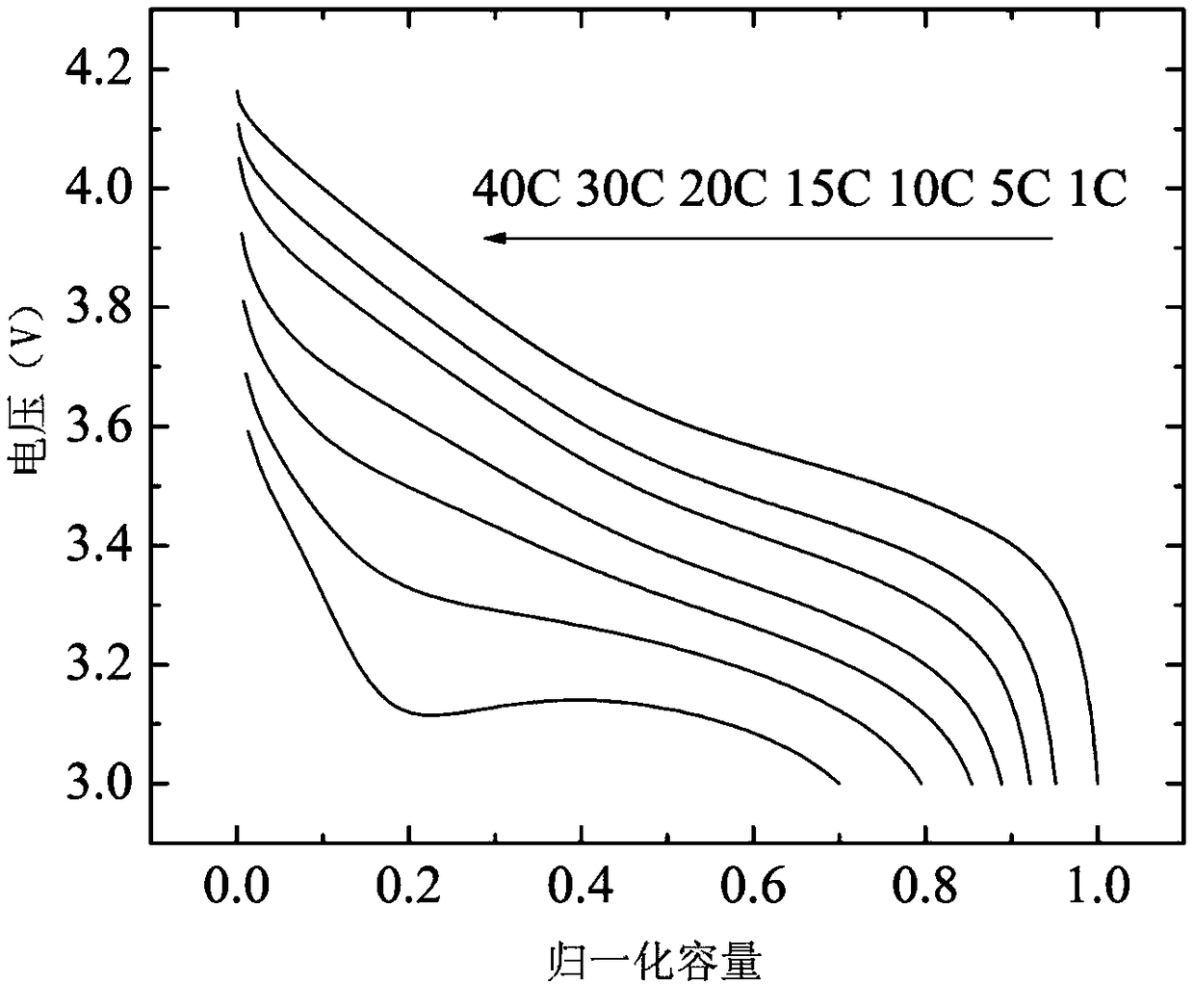

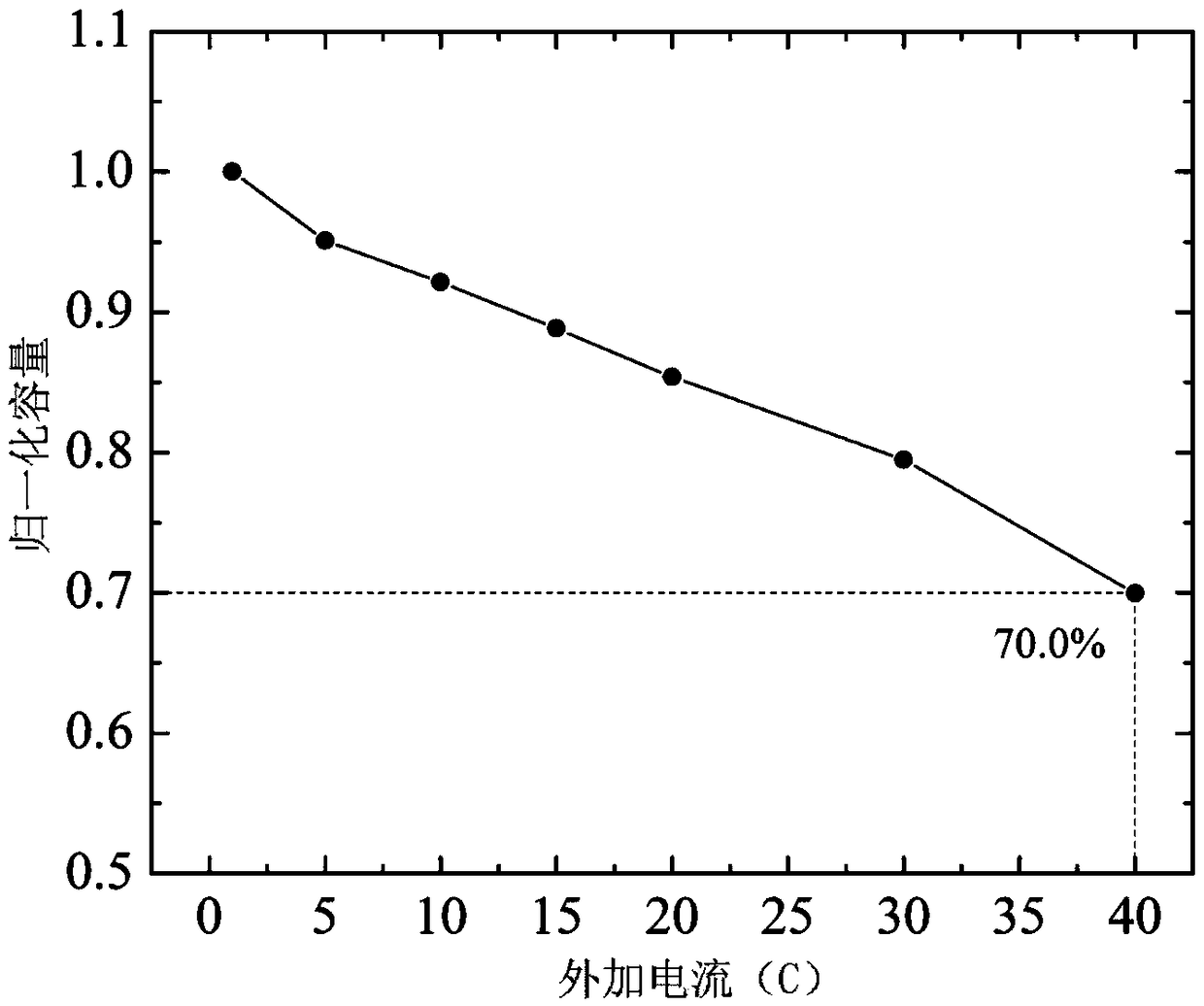

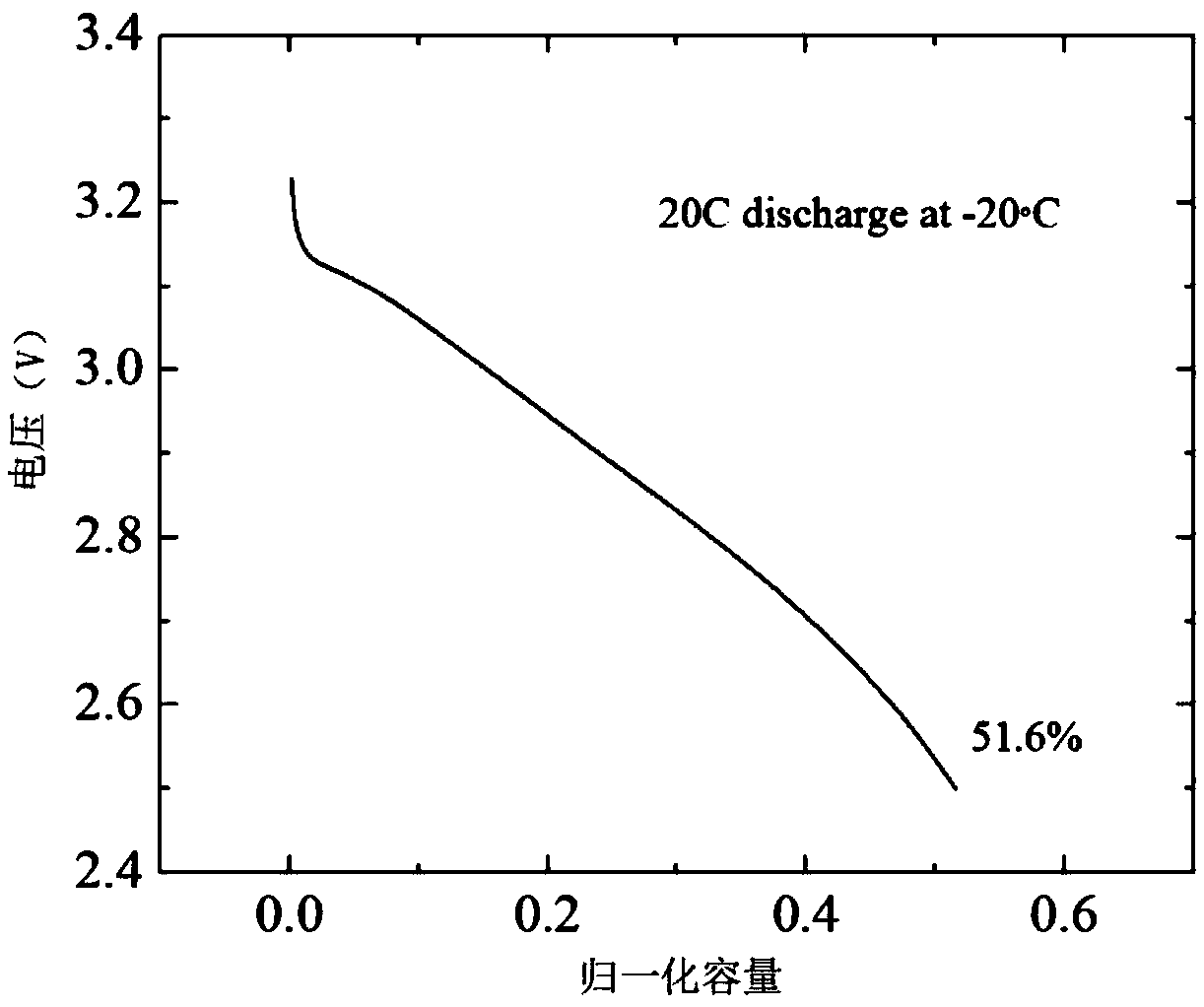

Prelithiation lithium ion start-stop power supply and preparation method thereof

InactiveCN108767242ASimple processLow costCell electrodesSecondary cells servicing/maintenanceLithiumStart stop

The invention discloses a prelithiation lithium ion start-stop power supply. The power supply comprises a positive electrode and a negative electrode. The positive electrode is mainly made of a LiNixCoyMnzO2 / Li5FeO4 composite material, wherein x+y+z=1. A preparation method of the prelithiation lithium ion start-stop power supply is also provided. The preparation includes the steps of preparing theLiNixCoyMnzO2 / Li5FeO4 composite material, preparing the positive electrode and the negative electrode of the power supply and assembling the positive electrode and the negative electrode into the lithium ion start-stop power supply. The start-stop power supply obtained by the preparation method has good specific energy, specific power, charge and discharge cycles and low temperature performance,and is suitable for industrial production.

Owner:洲际高能科技(北京)有限公司

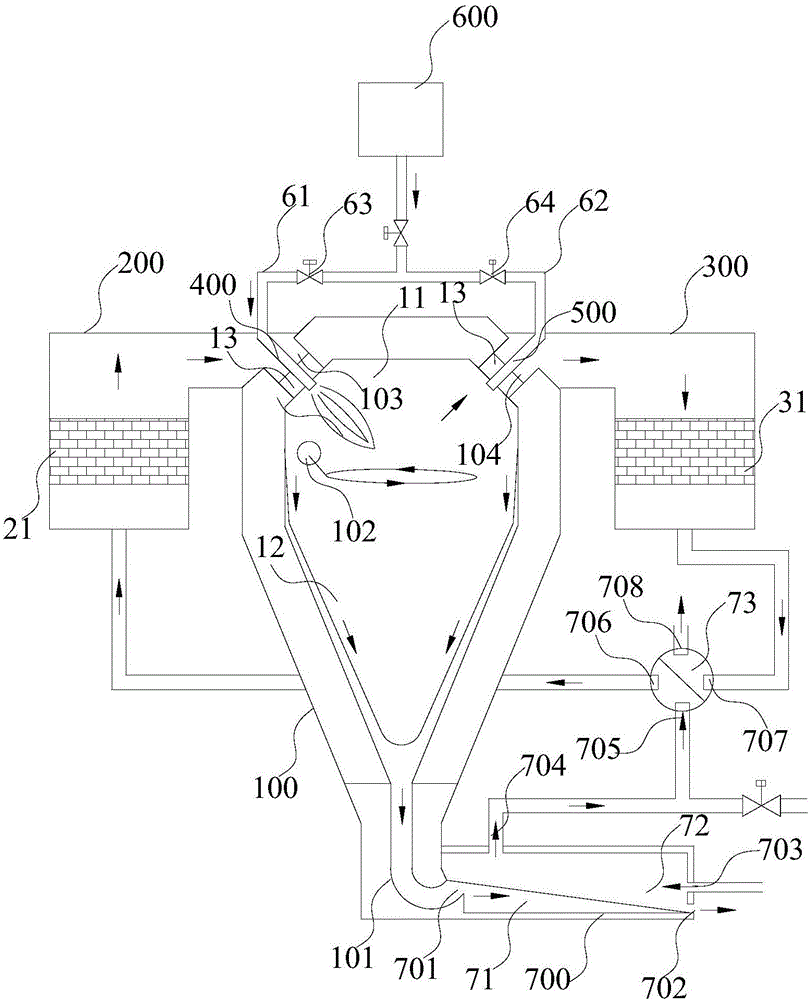

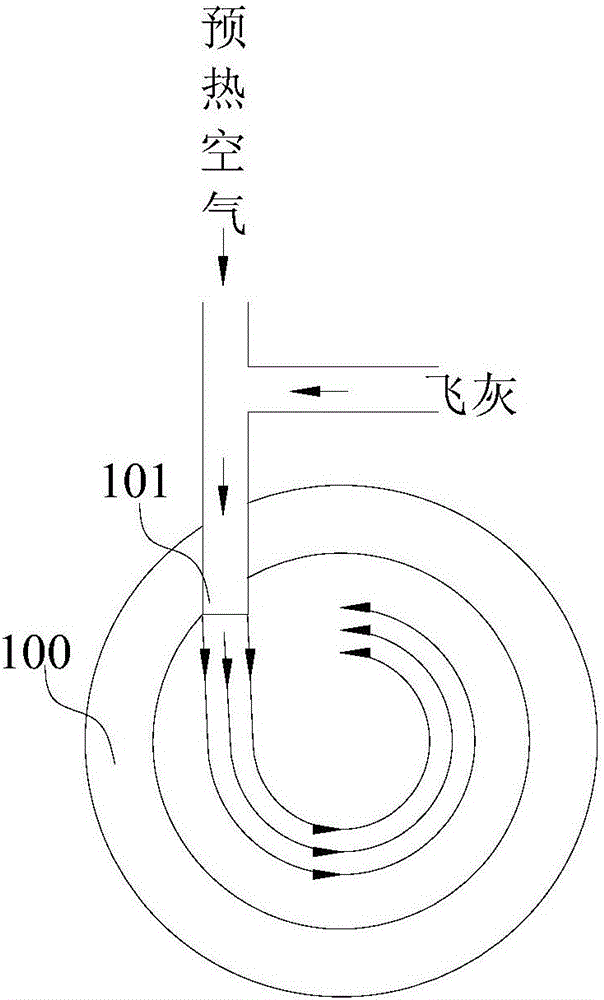

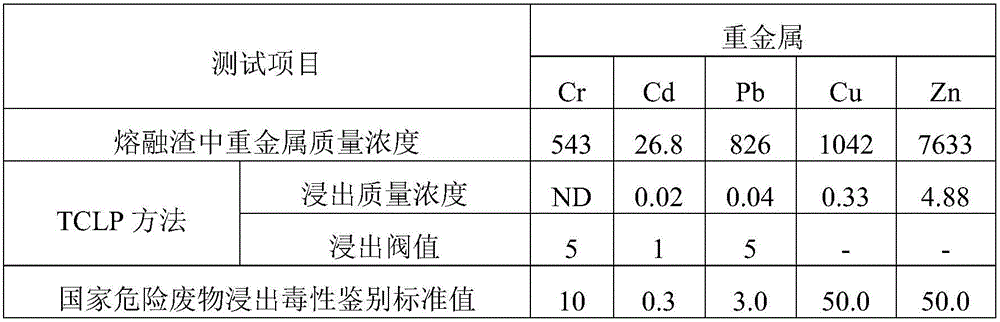

Heat-accumulating-type fly ash gasification smelting furnace

PendingCN106705057ARealize continuous dischargeImprove processing efficiencyIncinerator apparatusGas supplyFly ash

The invention discloses a heat-accumulating-type fly ash gasification smelting furnace. The heat-accumulating-type fly ash gasification smelting furnace comprises a hearth, a first heat storage chamber, a second heat storage chamber, a first nozzle, a second nozzle, a gas supply device, a fly ash inlet, a U-shaped slag outlet and a slag melting pond. A melting region and a deslagging region are defined inside the hearth. The first heat storage chamber communicates with the melting region through a first opening. The second heat storage chamber communicates with the melting region through a second opening. The first nozzle stretches into the melting region through the first opening. The second nozzle stretches into the melting region through the second opening. The gas supply device is connected with the first nozzle and the second nozzle. The fly ash inlet is formed in the hearth. The U-shaped slag outlet is formed in the lower end of the deslagging region. The slag melting pond comprises a slag melting chamber and a heat exchange chamber which are arranged in a spaced mode. The slag melting chamber is provided with a molten slag inlet and a glassy-state molten slag outlet. The molten slag inlet communicates with the U-shaped slag outlet. The heat exchange chamber is provided with a normal temperature air inlet and a preheated air outlet. The preheated air outlet is connected with the fly ash inlet and further communicates with the first heat storage chamber and the second heat storage chamber through a reversing valve. By the adoption of the heat-accumulating-type fly ash gasification smelting furnace, continuous melting treatment of rubbish fly ash can be achieved; and moreover, stability is high and energy consumption is low.

Owner:SHENWU TECH GRP CO LTD

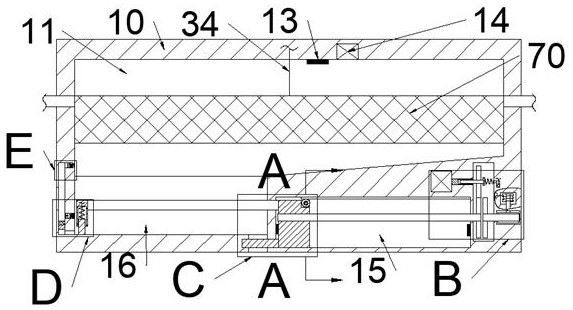

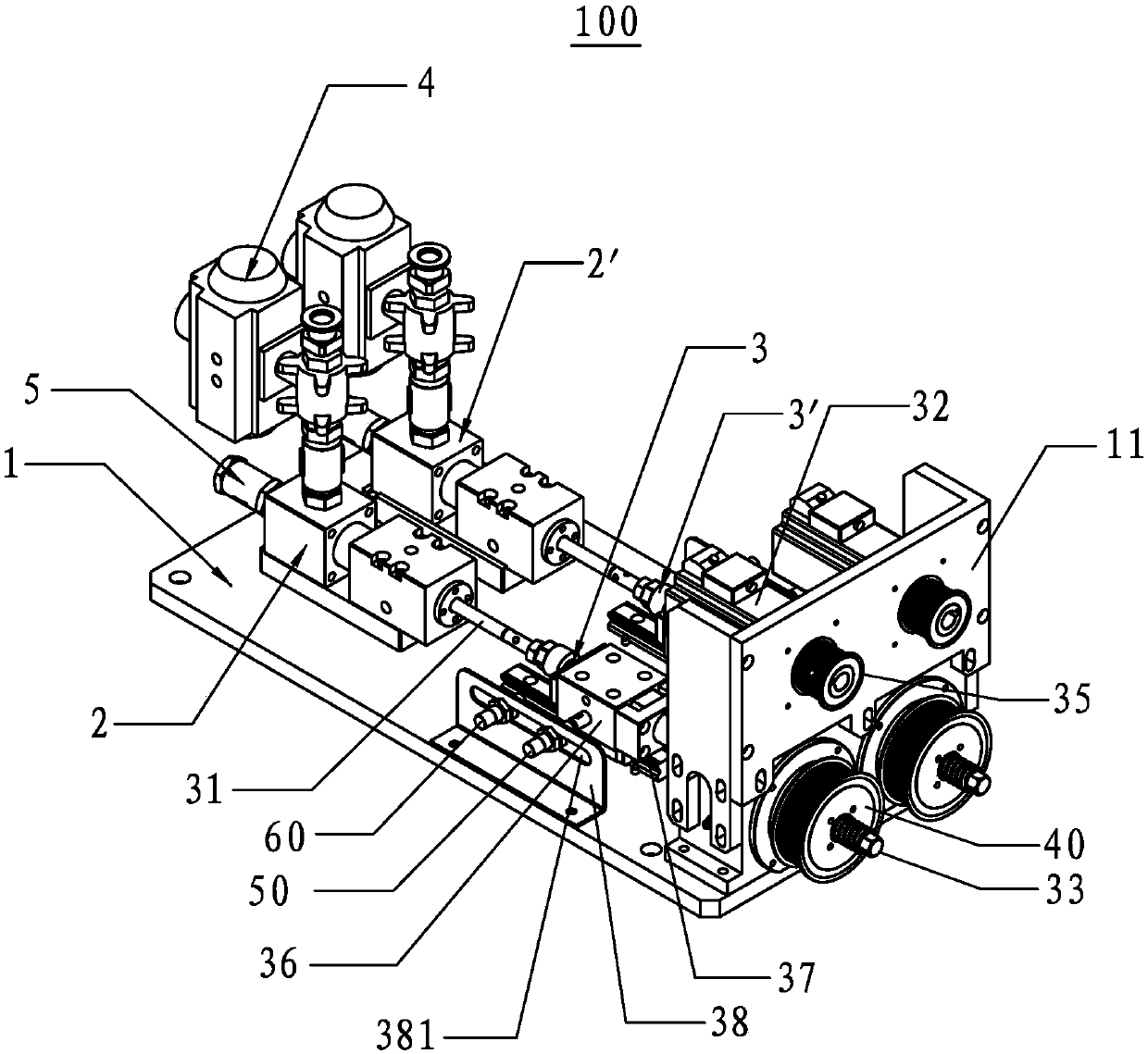

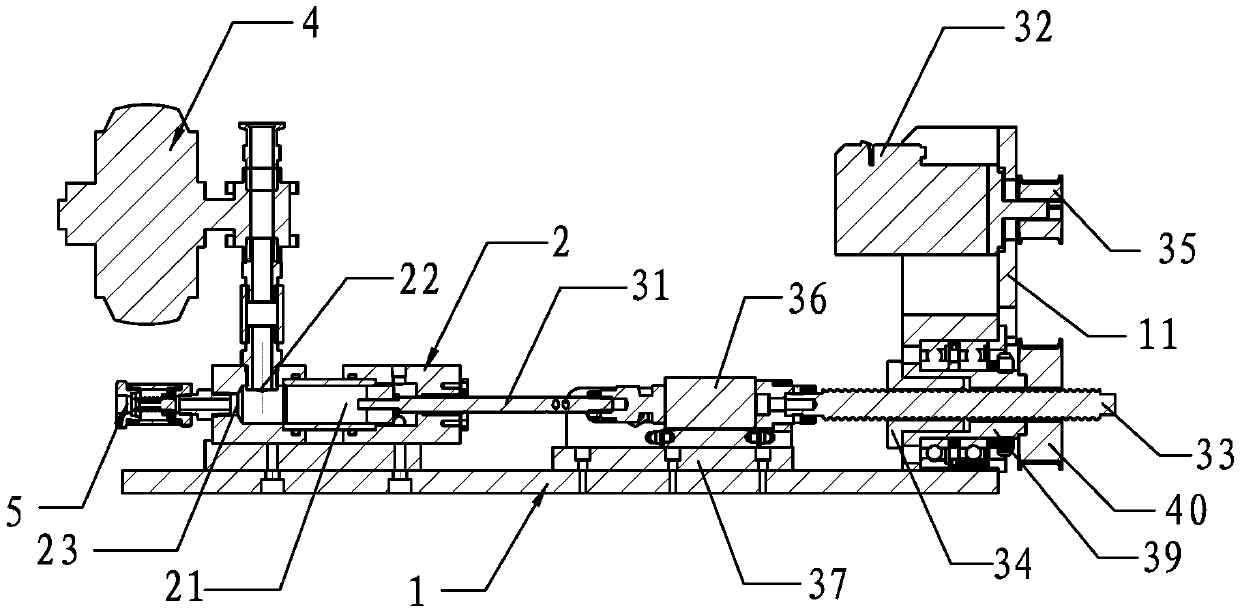

Two-way piston pump and control method thereof

ActiveCN106523318AUniform dischargeRealize continuous dischargePositive displacement pump componentsPump installationsReciprocating motionControl system

The invention is suitable for the field of piston pumps, and provides a two-way piston pump and a control method thereof. The piston pump comprises a control system, a first one-way metering pump, a second one-way metering pump, a first driving mechanism and a second driving mechanism; the control system controls operation or standing of the first and second driving mechanisms; the first and second one-way metering pumps are respectively connected with the first and second driving mechanisms; each one-way metering pump has a hollow cavity, a sucking port and a discharge port; the cavity is communicated with the sucking port and the discharge port; a pneumatic ball valve is mounted in the sucking port; a one-way valve is mounted in the discharge port; each driving mechanism includes a piston rod capable of extending; the end parts of the piston rods are inserted in the cavities of the one-way metering pumps, and perform a reciprocating motion in the cavities; and the control system controls the first and second driving mechanisms to drive reverse movement of the two piston rods. The piston pump has two sets of one-way piston metering pumps; one set is for feeding, and the other set is for discharging; and the two sets are alternately operated to realize continuous discharge of the piston pump.

Owner:SHENZHEN SECOND INTELLIGENT EQUIP CO LTD

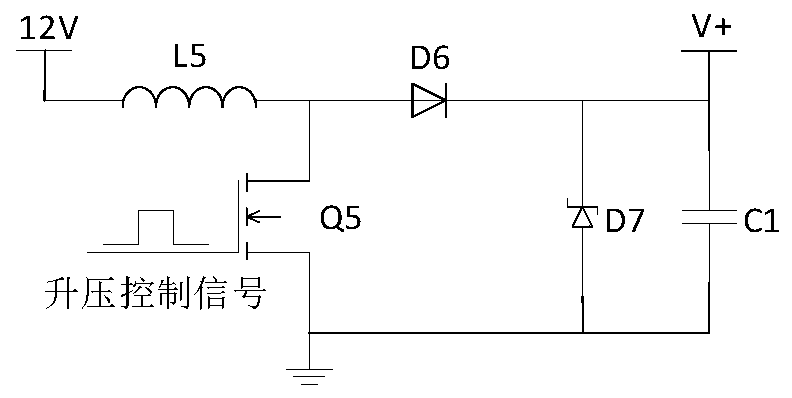

High-energy discharge ignition device and control method thereof

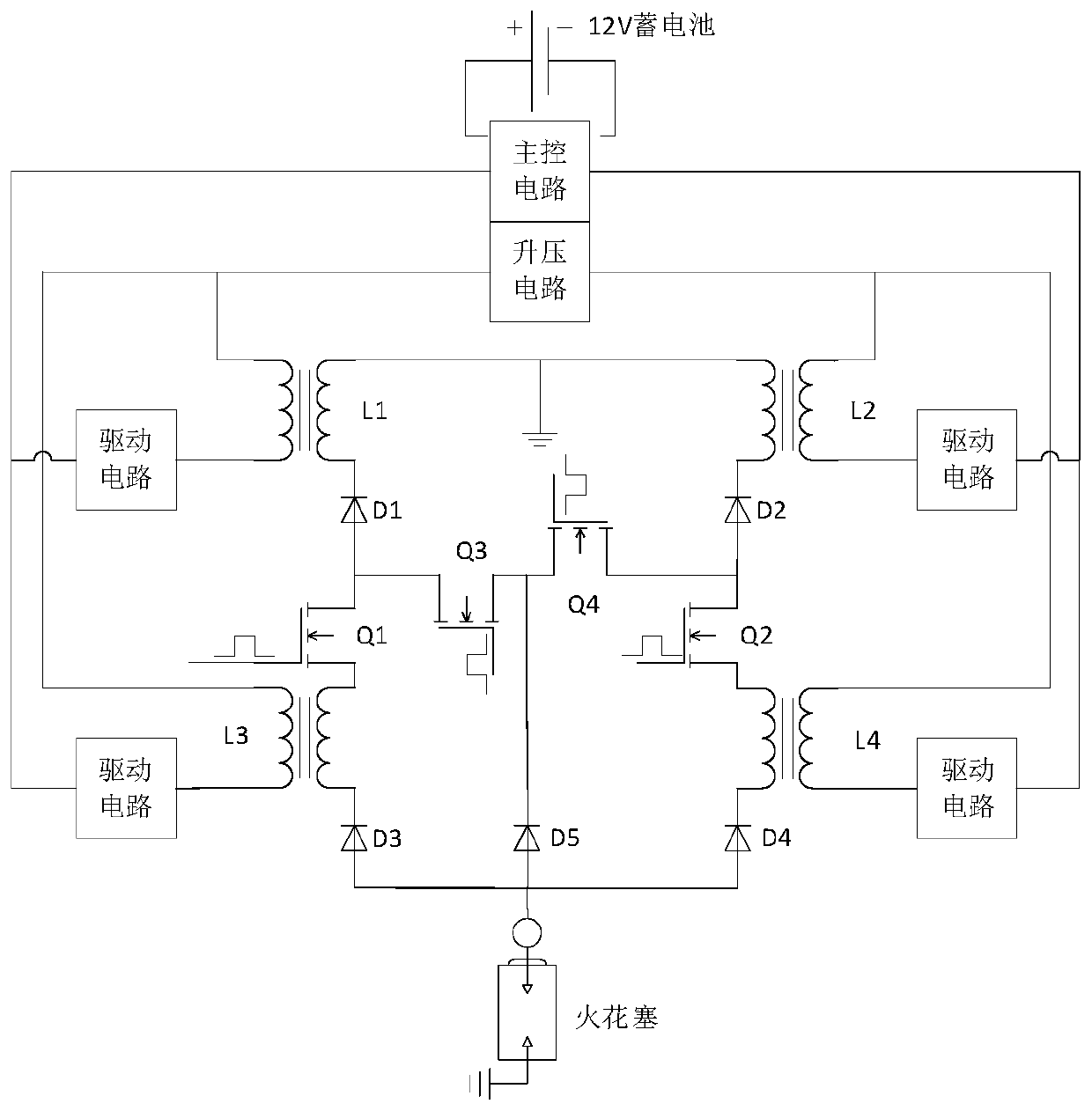

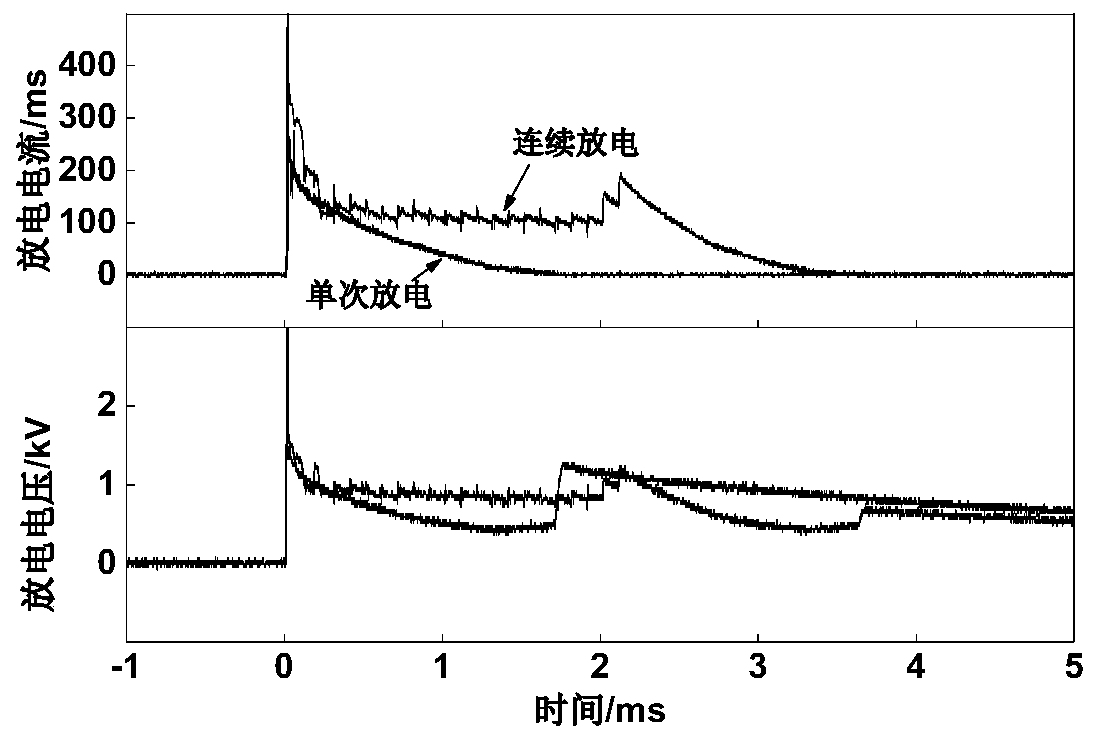

ActiveCN110206673AHigh breakdown capability outputRealize multiple dischargesMachines/enginesInstallations with induction energy storageIgnition coilHigh energy

The invention provides a high-energy discharge ignition device and a control method thereof. Independent charge-discharge control can be conducted on each ignition coil through a main control circuit,and through switching, the high-energy discharge ignition device can work on a double-coil parallel output mode and a four-coil serial-parallel output mode correspondingly with an MOS pipe. During turn-off operation of Q1 and Q2 of the MOS pipe and turn-on operation of Q3 and Q4, the ignition coils L1 and L2 discharge to the outside in a parallel form; and during turn-on operation of the Q1 and Q2 of the MOS pipe and turn-off operation of the Q3 and Q4, the ignition coils L1 and L3 are in series connection, the L2 and L4 are in series connection, discharge ability is improved, the two sets ofseries ignition coils are in parallel connection to discharge to the outside, and various discharge form output of higher energy and higher breakdown ability is achieved. Each ignition coil is independently controlled, charging can be conducted while the coils are in series connection, the coils are combined with a boosted circuit to supply power to a primary coil, fast coil charging is achieved,energy storage time is not increased on the basis that discharge ability is improved through the series coils, and high-frequency continuous discharge and other strategies are convenient to achieve.

Owner:SHANGHAI JIAO TONG UNIV

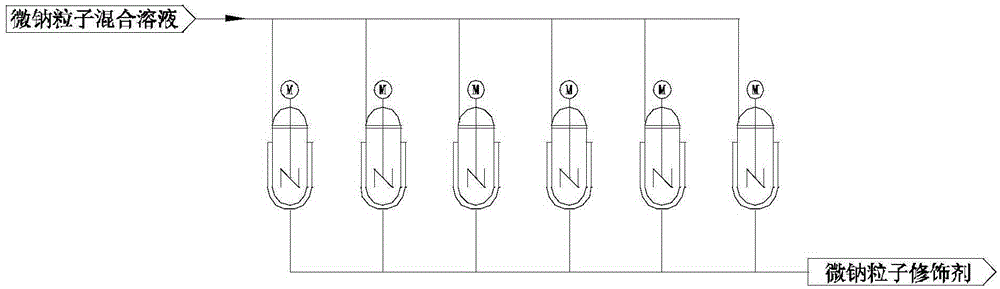

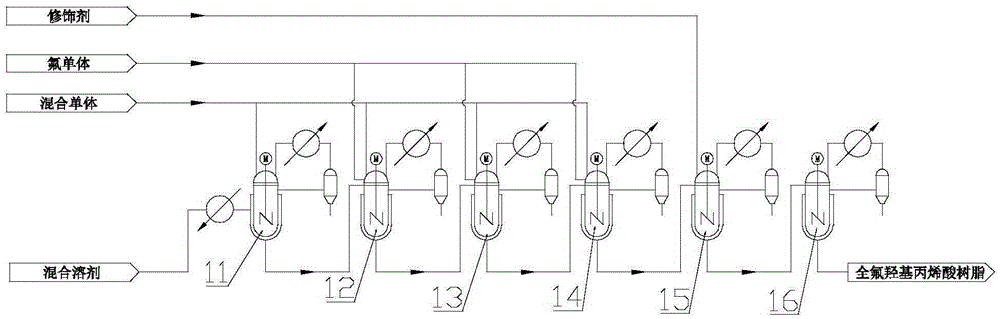

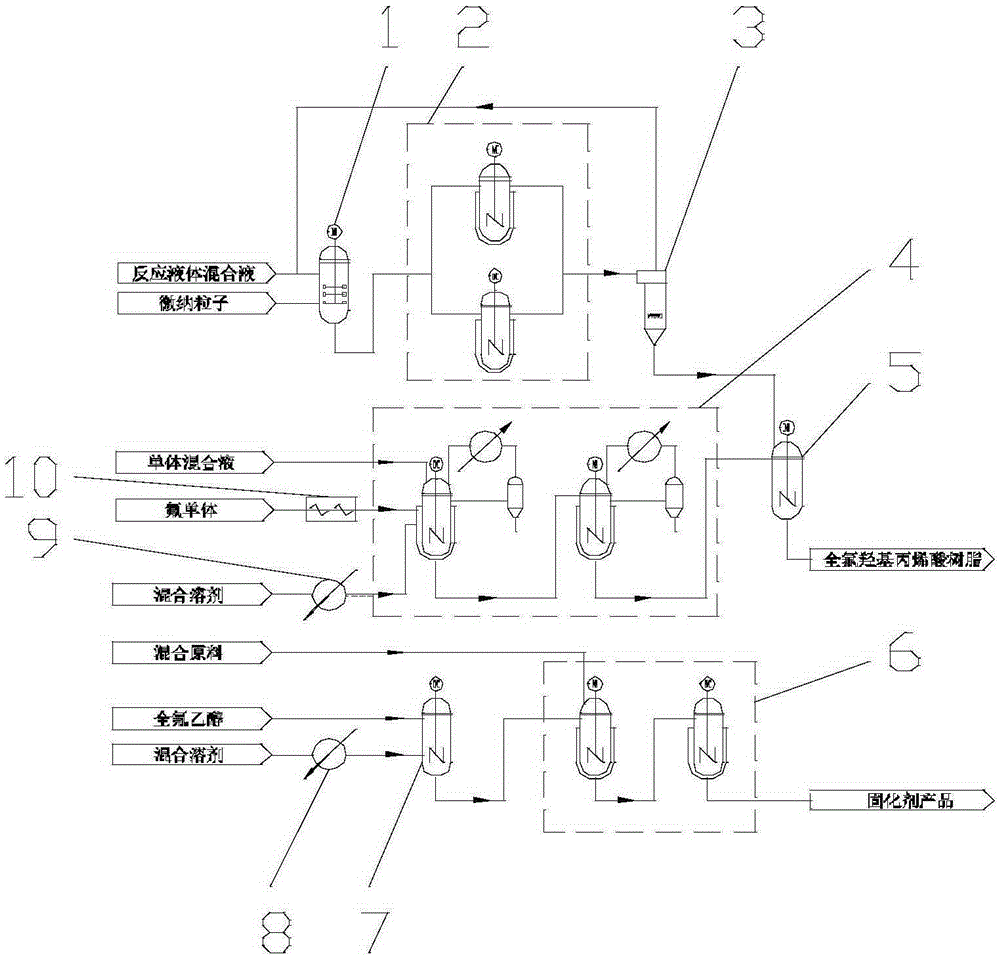

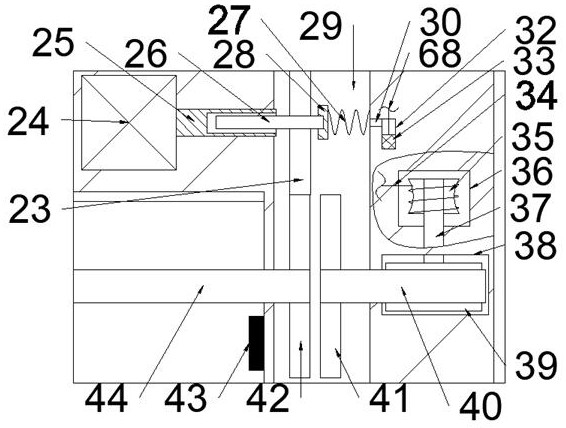

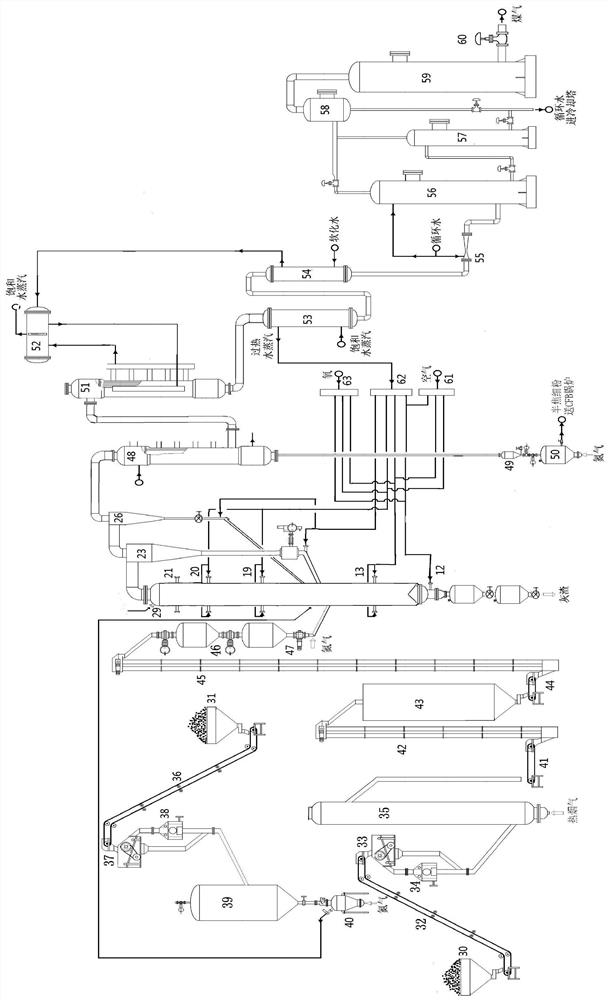

Device and method for producing super-amphiphobic paint with modification of modified particles

InactiveCN105315871ALower surface energySuperamphiphobicPolyurea/polyurethane coatingsAcrylic resinProcess engineering

The invention discloses a device and method for producing super-amphiphobic paint with modification of modified particles. The device comprises a super-amphiphobic paint component A production system and a super-amphiphobic paint component B production system. The super-amphiphobic paint component A production system comprises a first subsystem and a second subsystem. The first subsystem comprises a modified particle high-speed dispersing machine, a modified particle six-kettle parallel reaction device and a cyclone hydraulic separator. The second subsystem comprises a resin monomer raw material premixer, a fluorine-containing hydroxy-acrylic resin six-kettle series reaction device and a resin solvent preheater. The super-amphiphobic paint component B production system comprises a fluorine-containing PU prepolymer curing agent double-kettle series reaction device, a prepolymer raw material stirrer and a prepolymer raw material preheater. The device is capable of achieving consecutive production, convenient to maintain and good in achievability, and a process adopted in the method is simple.

Owner:SOUTH CHINA UNIV OF TECH

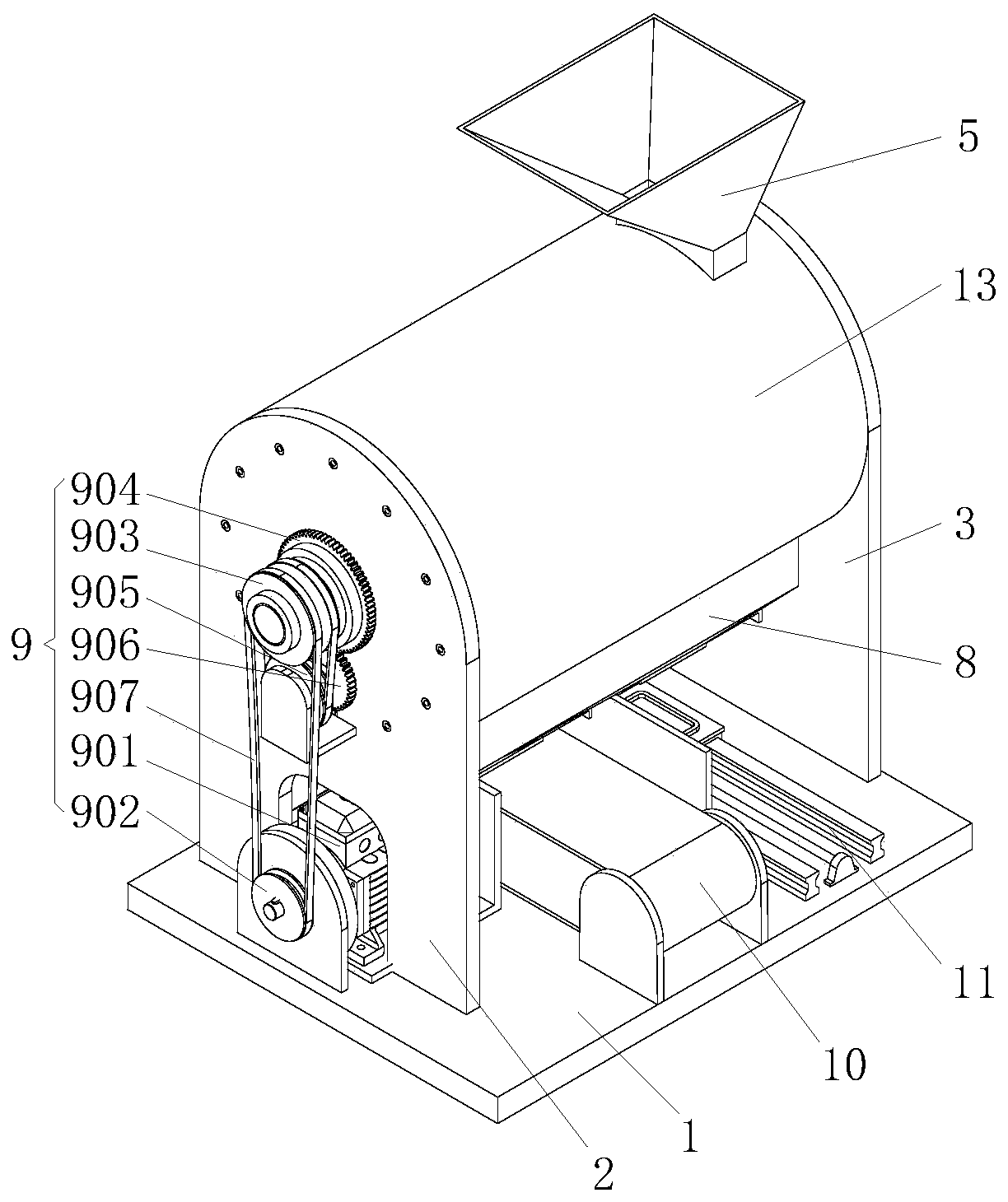

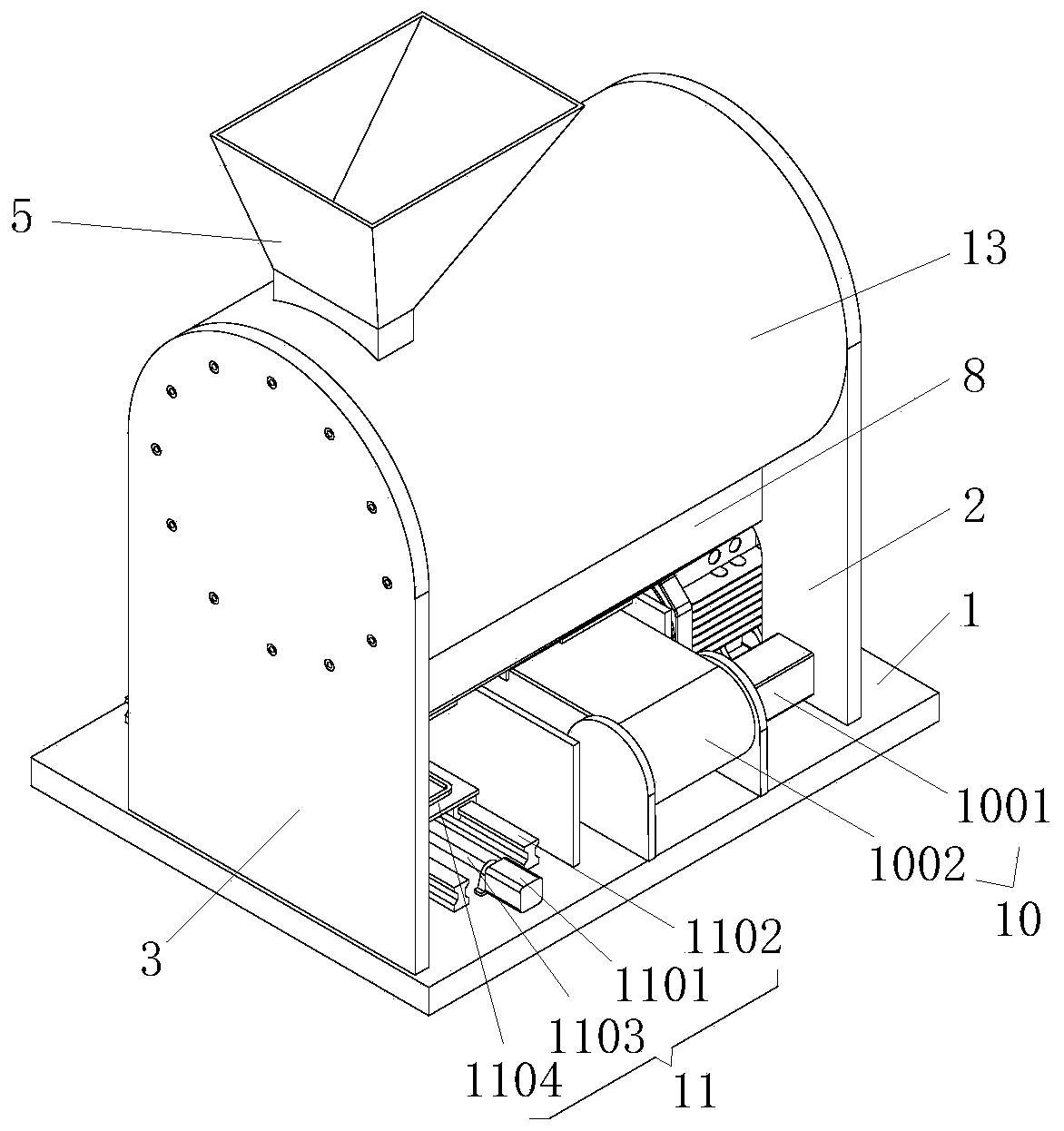

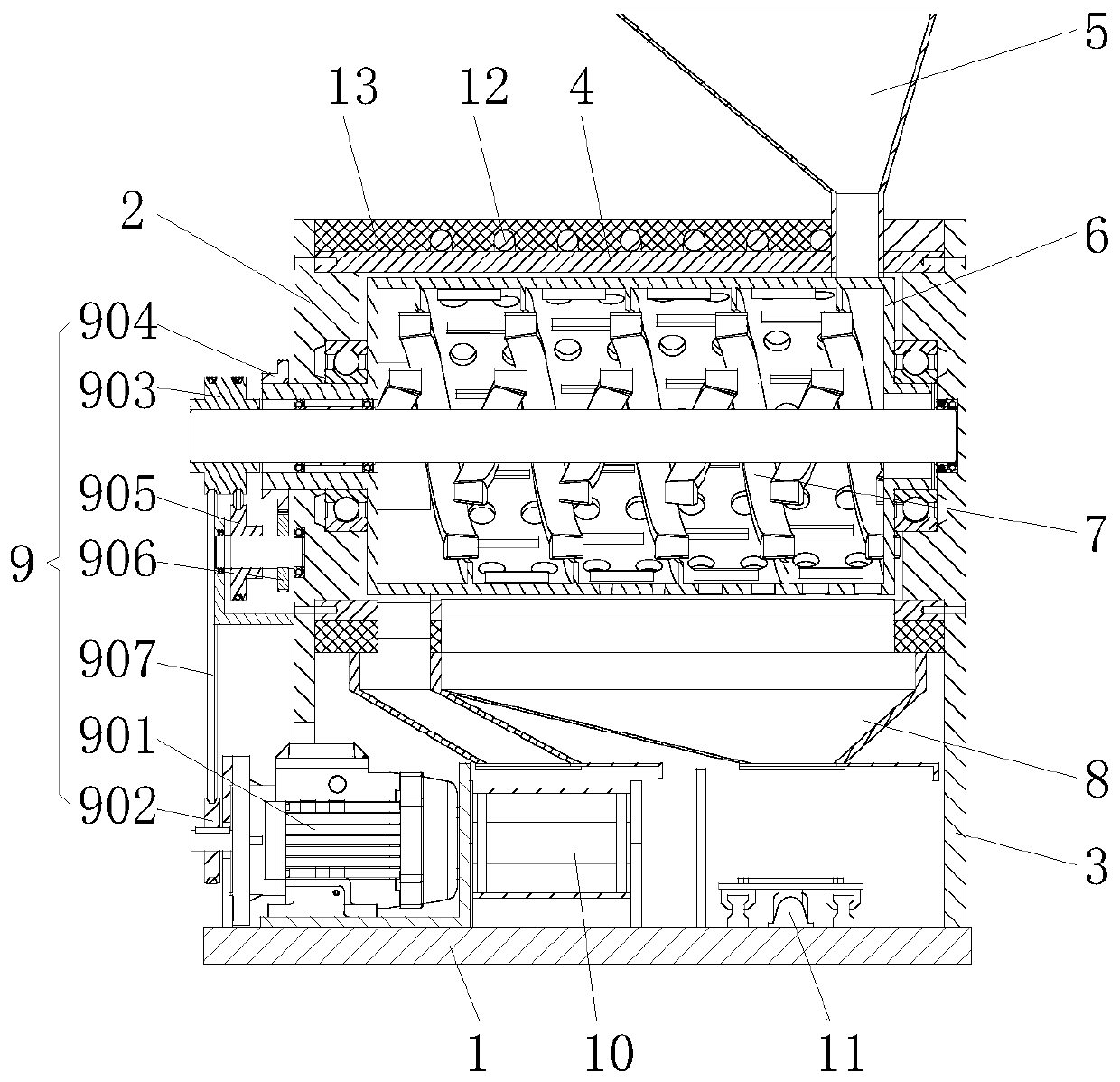

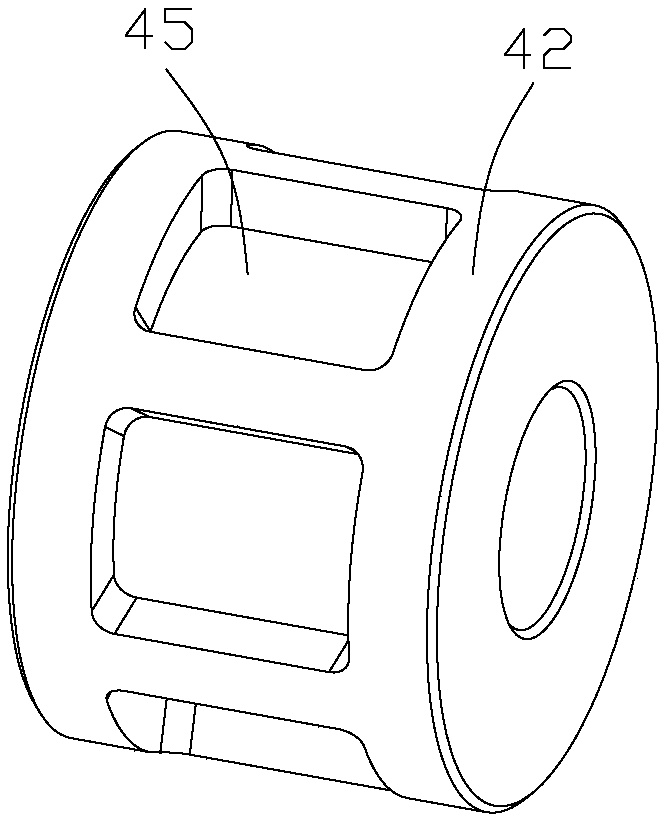

Battery electrode plate surface layer substance separator

ActiveCN111082179AImprove continuityAchieve separationWaste accumulators reclaimingBattery recyclingPower apparatusMechanical engineering

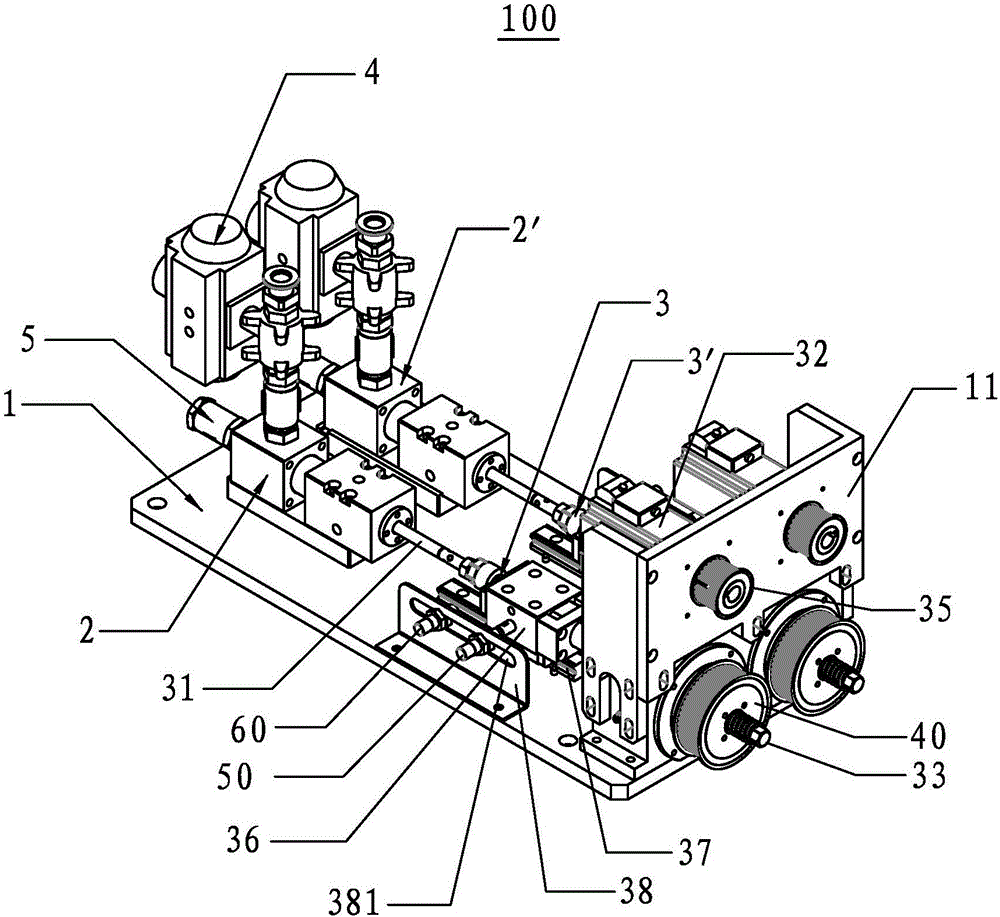

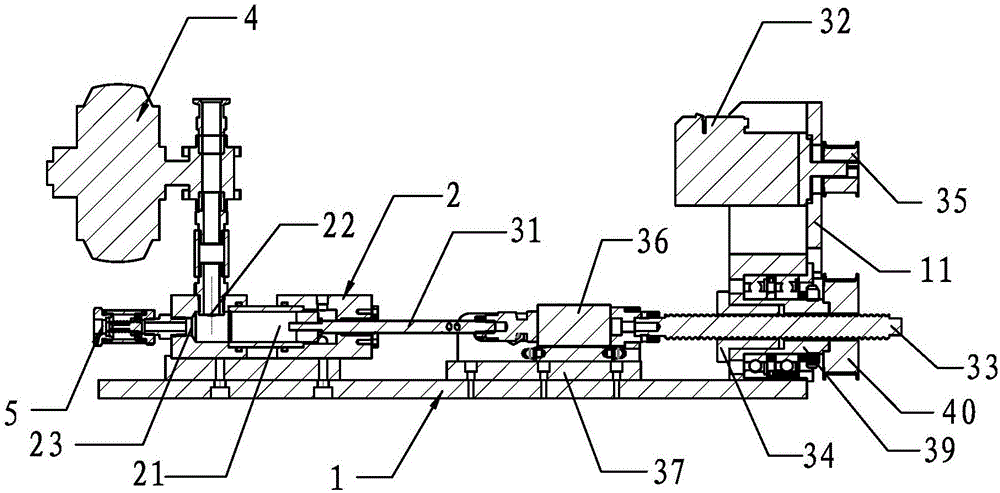

The invention relates to the technical field of waste battery recovery treatment, and discloses a battery electrode plate surface layer substance separator. The battery pole piece surface layer objectseparator comprises a machine base, a left supporting plate and a right supporting plate, wherein the left supporting plate and the right supporting plate are fixed to the top surface of the machinebase, an outer barrel is fixed to the top of the left supporting plate and the right supporting plate, a feeding hopper is fixed to one side of the top of the outer barrel, an inner barrel is rotationally arranged in the outer barrel, a discharging hopper is fixedly arranged at the bottom of the outer barrel, a mixer is rotationally arranged in the inner barrel, and a power device for driving theinner barrel and the mixer to rotate at the same time is arranged on the top surface of the machine base. Continuous feeding and continuous oscillation separation of the to-be-separated electrode plates and continuous discharging and separated collection of separated substances are achieved, and the separator has the advantages of being high in single-time separation rate of surface layer substances of the electrode plates, high in working efficiency and safe in operation.

Owner:HEFEI UNIV OF TECH

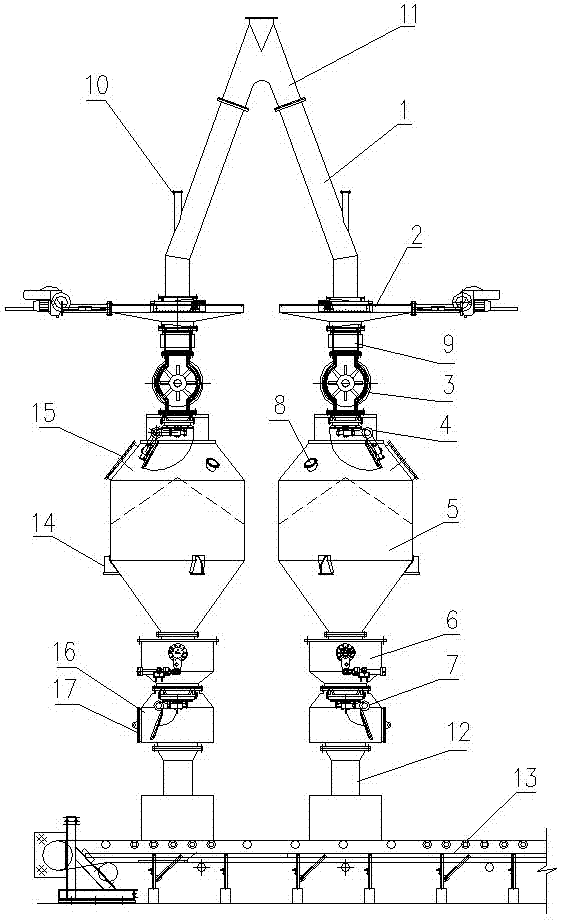

Material discharge device for vertical furnace

InactiveCN102925614ARealize continuous dischargeEnsure continuous and efficient operationShaft furnaceEngineeringGate valve

The invention discloses a material discharge device for a vertical furnace, comprising a material blanking pipe, a gate valve, a rotating material discharge valve, an upper sealing valve, a discharged material tank, a material flow regulating valve and a lower sealing valve. The material discharge pipe is provided with at least two material dividing pipes; the gate valve is arranged at the inlet of the material discharge pipe or the outlets of the material dividing pipes; the rotating material discharge valve is arranged on the material dividing pipes and below the gate valve; the upper sealing valve is connected with the outlet of the rotating material discharge valve or the outlets of the material dividing pipes; the discharged material tank is connected with the outlet of the upper sealing valve; the material flow regulating valve is connected with the outlet of the discharged material tank; the lower sealing valve is connected with the outlet of the material flow regulating valve; and the discharged material tank is provided with a uniform pressure discharge interface. Due to the alternative work of equipment on the material flow paths of the material dividing pipes, the furnace material can be discharged continuously, and the vertical furnace can work continuously and efficiently. As the discharged material tank is provided with the uniform pressure discharge interface, the vertical furnace can discharge materials smoothly under pressure or normal pressure, and the material discharge device can work reliably and stably. The equipment in the material discharge device adopts the module design and can be repaired independently, so that the repair time is saved, and the maintenance cost is reduced.

Owner:CISDI ENG CO LTD

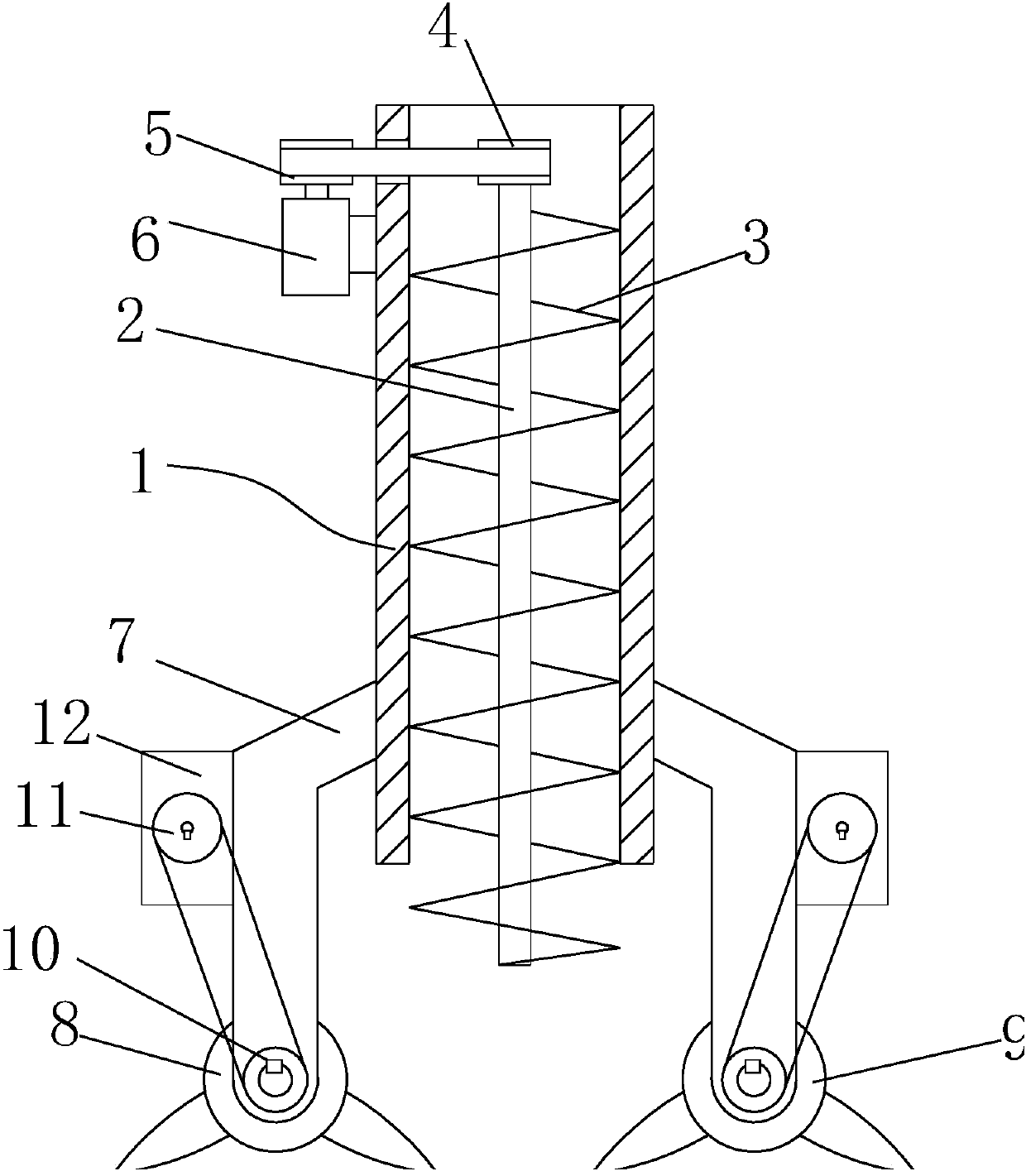

Silt cleaning device

InactiveCN107663871ARealize continuous dischargeImprove cleaning efficiencySoil-shifting machines/dredgersDrive wheelHelical blade

A sludge cleaning device mainly includes a discharge cylinder, the middle part of the discharge cylinder is provided with a rotating rod, the rotating rod is connected to the spiral blade, and the upper end of the rotating rod is connected to the driving motor through a driven wheel and a driving wheel. Both sides of the bottom of the discharge cylinder are connected to the discharge assembly A and discharge assembly B through the connecting frame, and one side of the discharge assembly A and discharge assembly B is connected to the driven pulley, and the driven pulley is connected to the driving The pulley is connected, and the driving pulley is connected with the discharge motor. The present invention can realize the continuous discharge of silt during use, effectively improves the cleaning efficiency of silt, has low cost, and effectively improves the working environment.

Owner:刘毓玉

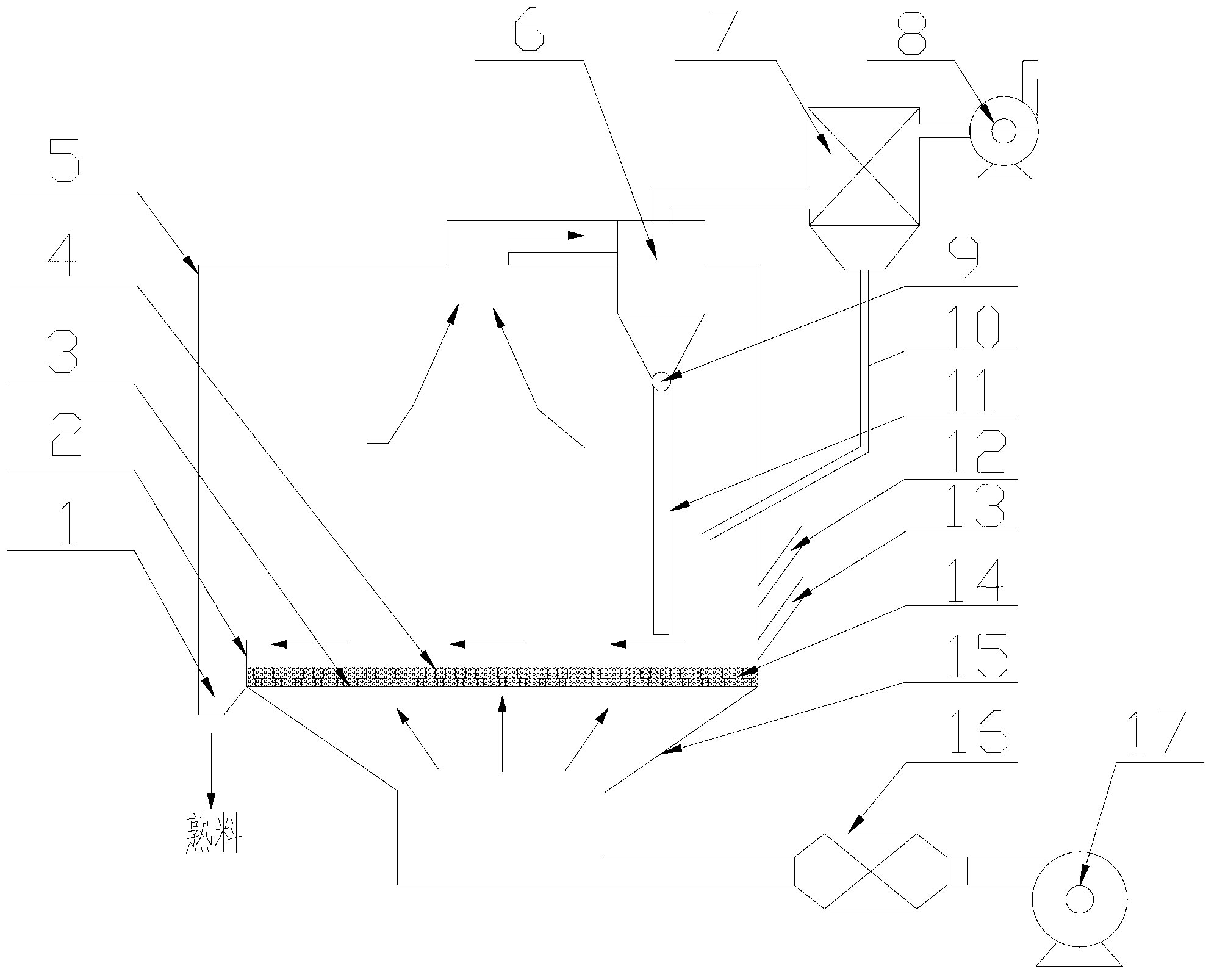

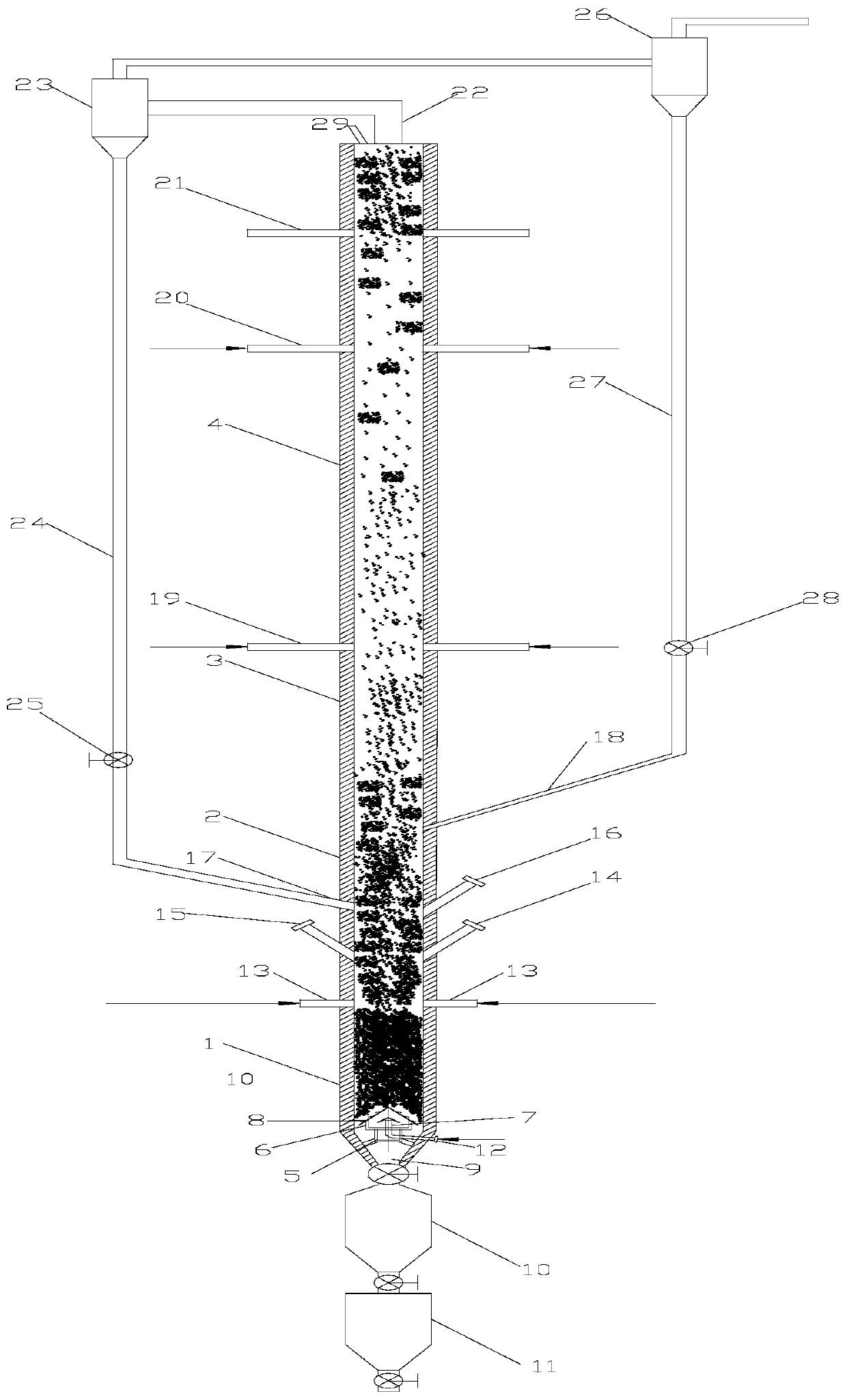

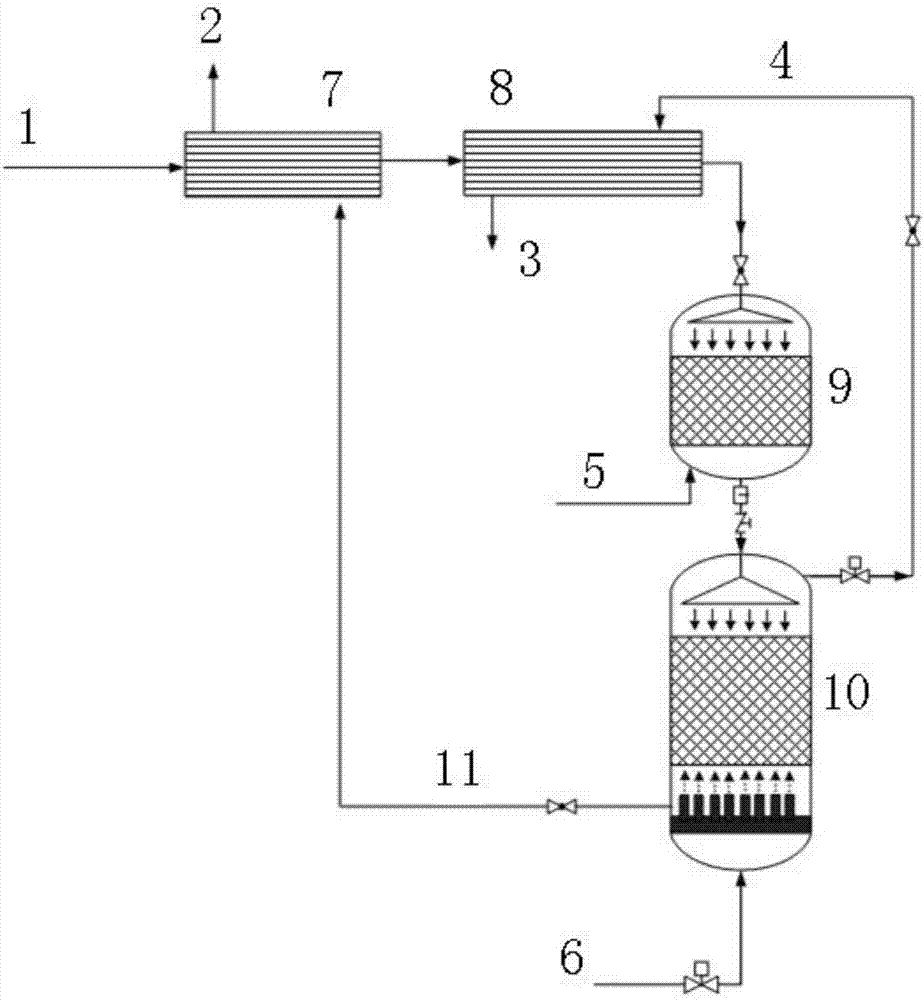

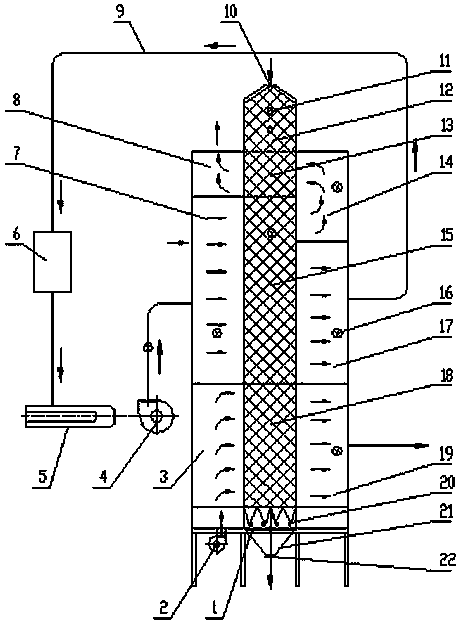

Fluidized bed reactor

InactiveCN102836677AEasy to separateRealize continuous dischargeChemical/physical processesAir preheaterFlue gas

A fluidized bed reactor comprises a shell, wherein a wind distribution plate which horizontally supports materials and meets the requirements of fluidization wind distribution is arranged in the shell; a wind cap is arranged on the wind distribution plate; a wind chamber is arranged below the wind distribution plate and is connected with the outlet of an air pre-heater; the air pre-heater is connected with an air blower; a separator for performing material separation to the flue gas is arranged in the shell; the inlet of the separator is formed above the inner part of the shell and is arranged horizontally; a separated material outlet of the separator is connected with the upper end of a falling pipe; the lower end of the falling pipe is arranged below the inner part of the shell; the flue gas outlet of the separator is arranged above the outer part of the shell; and a feeding opening and an inert material feeding opening are formed on the side of the shell so as to realize the continuous feeding and supplement of the inert material; by adoption of the reactor, the material particle abrasion amount can be reduced, the reaction time of the reaction material in the reactor is prolonged, the reactor can be controlled remotely; in addition, the reactor has the following advantages that the reaction efficiency is high, a mass of materials can be processed continuously, stably and efficiently, and the product quality is stable.

Owner:HUANENG CLEAN ENERGY RES INST

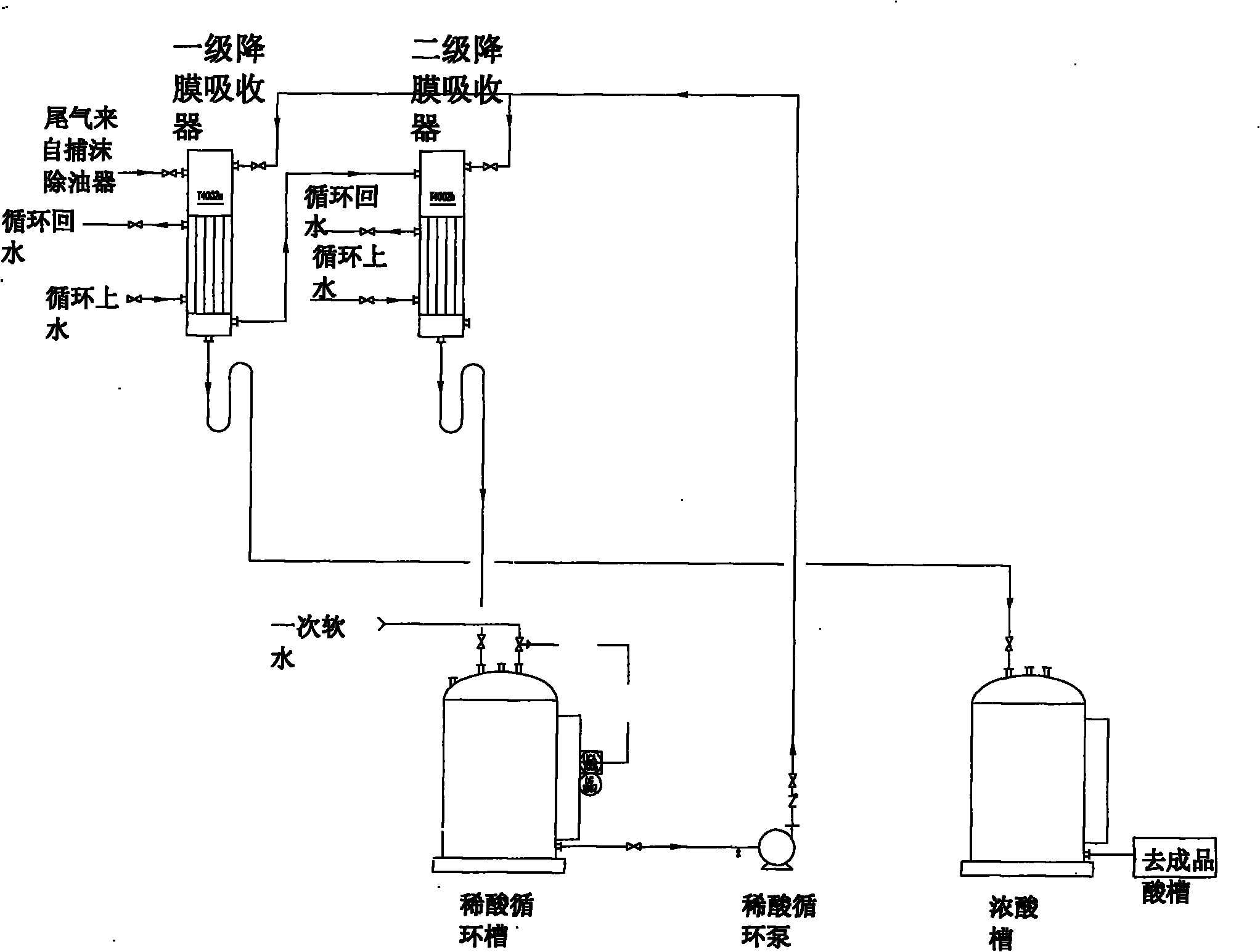

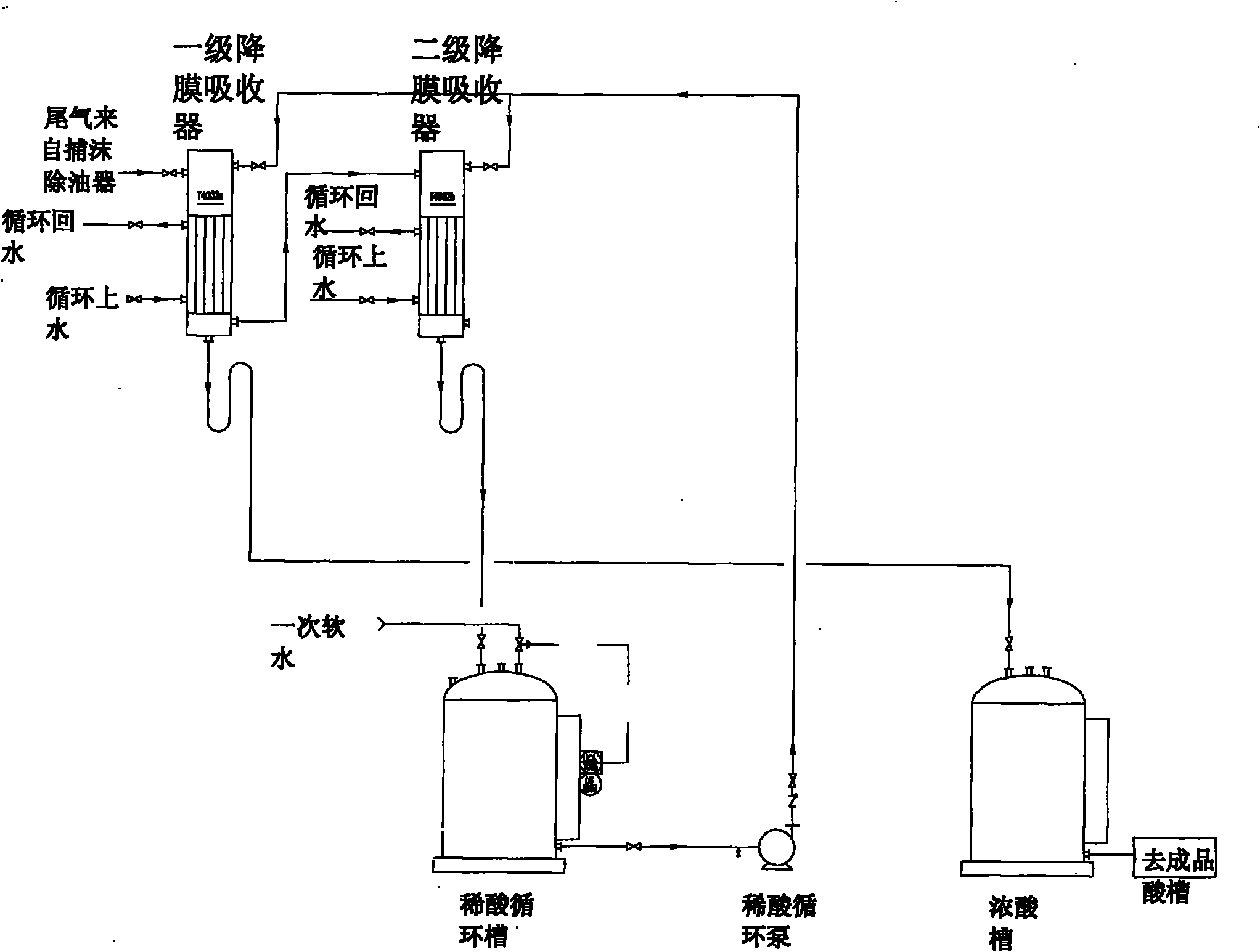

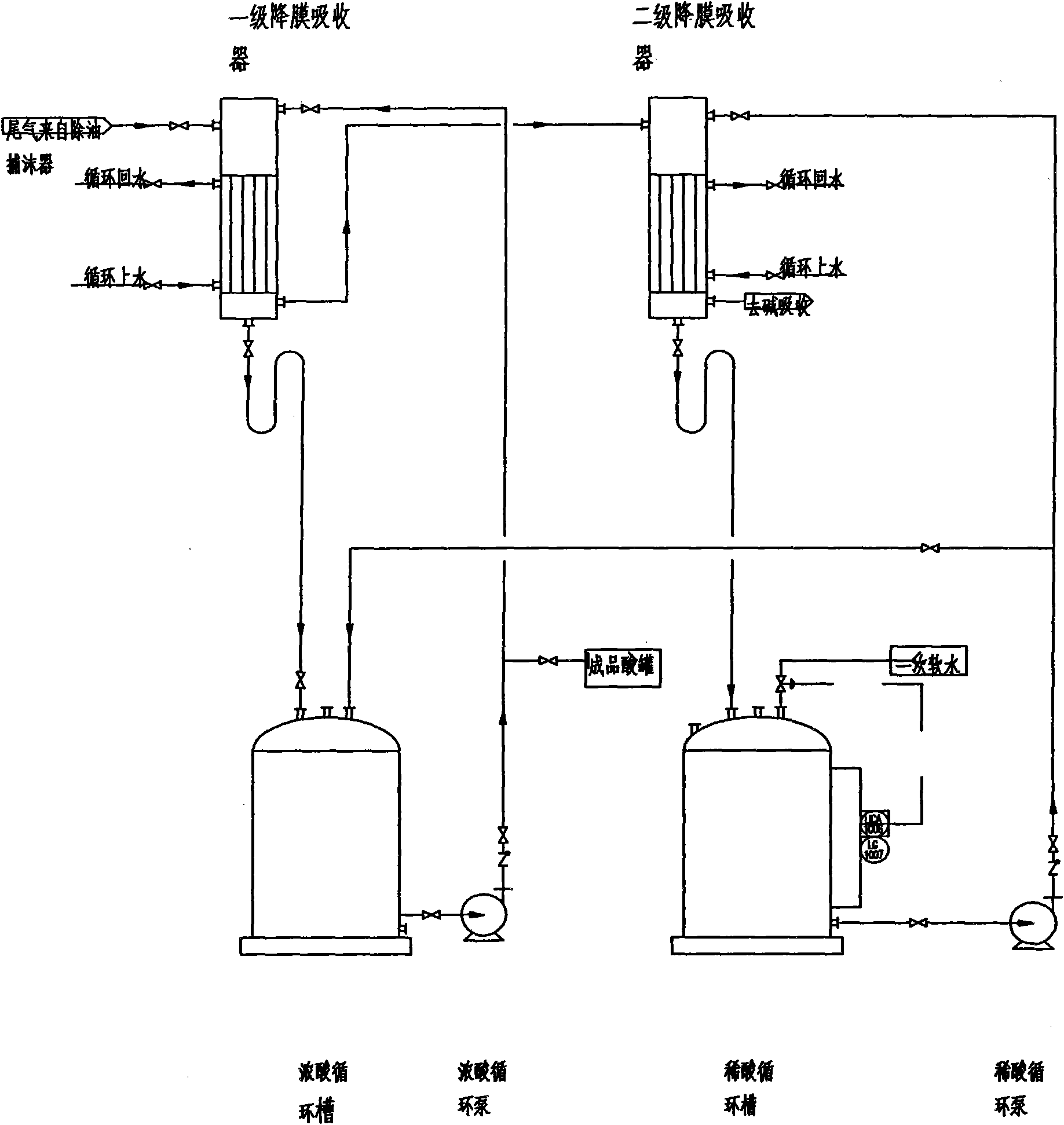

Chlorcosane tail gas absorption technology and equipment

InactiveCN101810986ARealize continuous dischargeGuaranteed stabilityDispersed particle separationAcid concentrationCirculating pump

The invention relates to a chlorcosane tail gas absorption technology and equipment. Chlorcosane tail gas firstly enters a first-grade falling film absorber; after adsorbing hydrogen chloride gas, the first-grade falling film absorber recovers finished product acid and then the recovered finished product acid enters a concentrated acid slot, and residual hydrogen chloride gas enters a secondary-grade falling film absorber; dilute acid can be obtained after being adsorbed by the secondary-grade falling film absorber; recovered dilute acid enters into a dilute acid circulating slot; dilute acid in the dilute acid circulating slot is sent out by the dilute acid circulating pump, parts of dilute acid enter a secondary-grade falling film absorber for cycle absorption, and other parts enter the first-grade falling film absorber and are absorbed and then enter the concentrated acid slot. Compared with the prior art, the invention saves one concentrated acid circulating pump, realizes continuous discharging of finished acid and ensures the stability of acid concentration.

Owner:LIAOCHENG LUXI CHEM ENG DESIGN

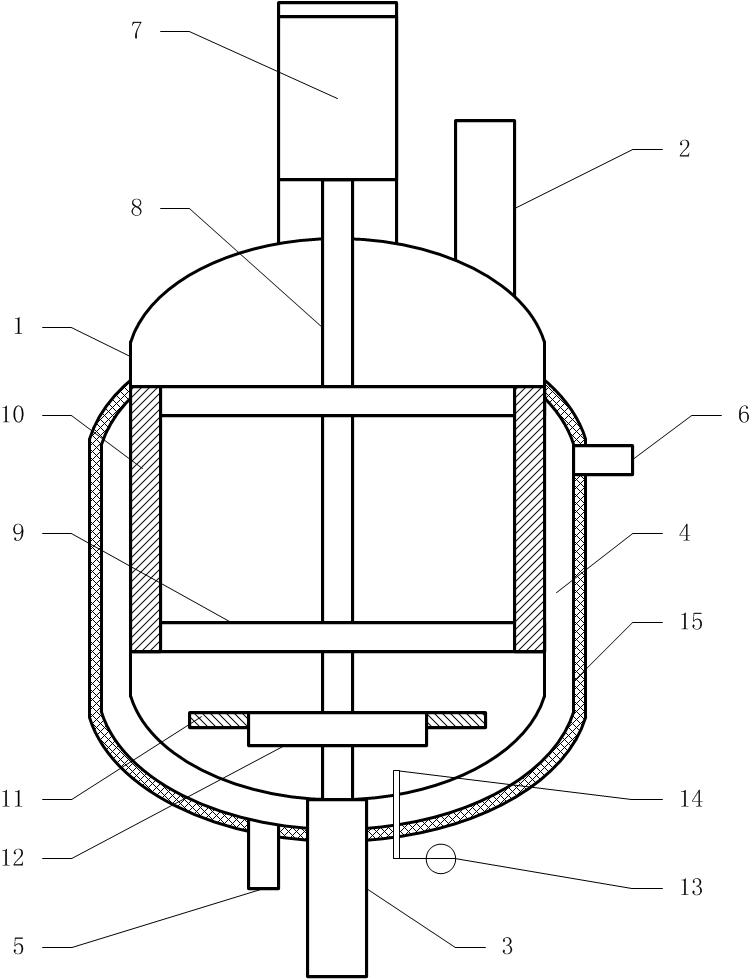

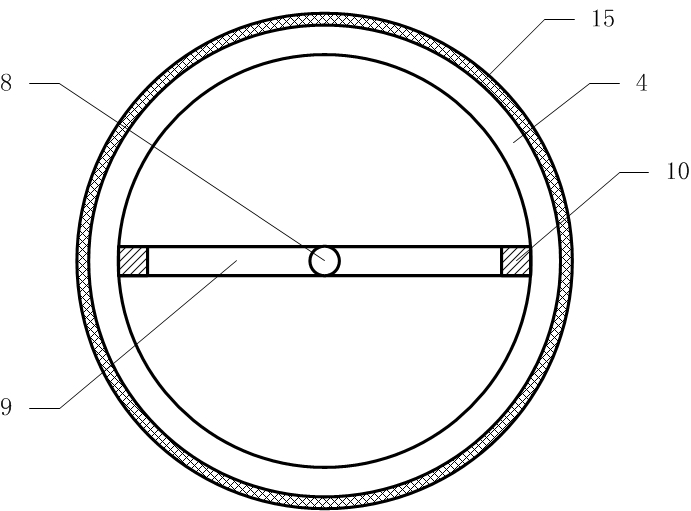

Viscous material cooling reactor

InactiveCN108671864BExtended storage timeSufficient heat exchangeChemical/physical/physico-chemical stationary reactorsChemical industryThermodynamics

The invention provides a reaction kettle for cooling a viscous and dense material. The reaction kettle comprises a kettle body, a jacket, a stirring paddle, a scraper, a shunt plate, a suction paddle,a thermometer and the like. The stirring paddle and the scraper are designed integrally to ensure that the viscous and dense material has axial and radial flows at the same time; and the scraper continuously scrapes away heat-exchanged materials to ensure that the viscous and dense material can fully exchange heat, the temperature distribution is uniform, and the cooling speed and efficiency areeffectively improved. The shut plate settles the cooled viscous and dense material at the bottom of the kettle body in sections, and the suction paddle assists in axial circulation to improve the heatexchange efficiency and realize continuous discharge in a cooling process. The reaction kettle solves environmental protection problems during filling and natural cooling of materials with high temperatures, and meanwhile greatly shortens the production period, effectively prolongs the storage time of materials and improves the quality of products. The reaction kettle has the characteristics of simple structure, low cost and convenient operation. The reaction kettle can be widely applied in food, feed, chemical industry, pharmacy and other fields requiring rapid cooling of viscous and dense materials.

Owner:荣成惠德环保科技有限公司

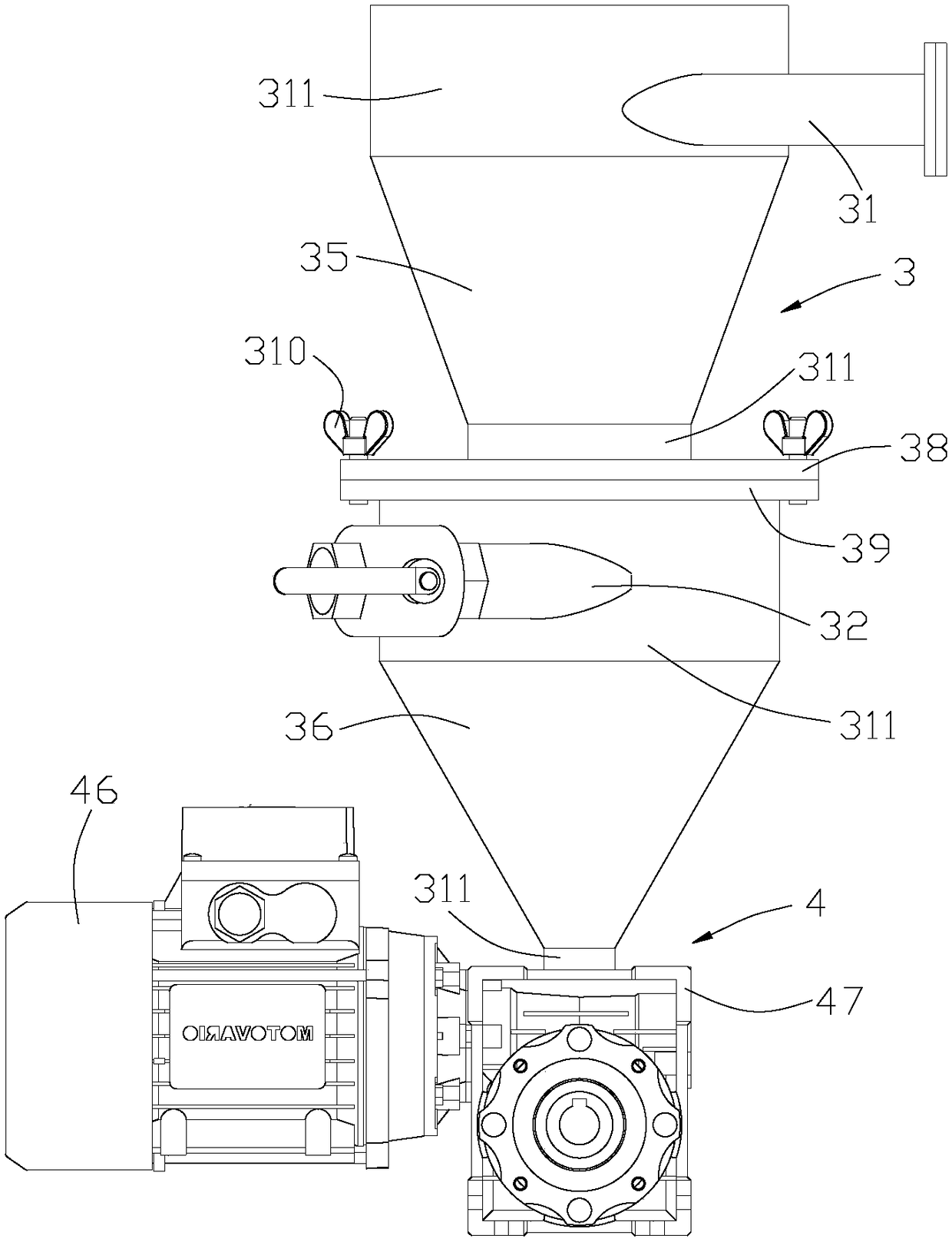

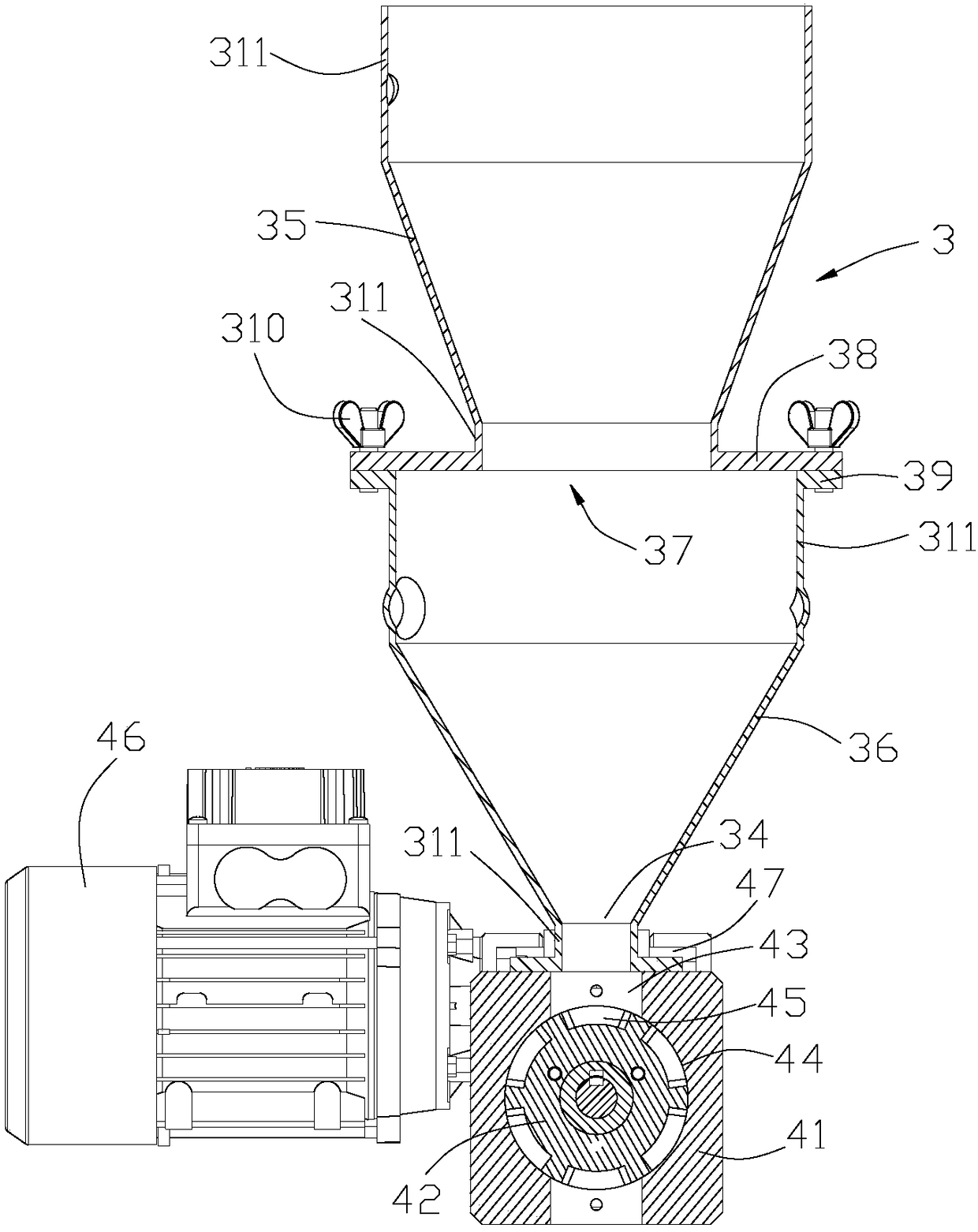

Feeding mechanism for food processing

InactiveCN106742293AAchieve hybridRealize continuous dischargeMixersPackagingHelical bladeDrive motor

The invention relates to a feeding mechanism for food processing. The feeding mechanism comprises a mechanism shell, a feed opening A is formed in one side of the upper end of the mechanism shell, a feed opening B is formed in the other side of the upper end of the mechanism shell, fixed supports are arranged at the bottom of the mechanism shell, a discharge hole is formed in one side of the bottom, a drive motor A is arranged on one side of the mechanism shell and connected with a rotating rod A, the rotating rod A is connected with a helical blade A, a drive motor B is arranged on the other side of the mechanism shell and connected with a rotating rod B, the rotating rod B is connected with a helical blade B, and discharge blades are arranged in the central position inside the mechanism shell. When the feeding mechanism works, raw materials needing to be packaged are added into the mechanism shell from the feed opening A and the feed opening B, at the moment, mixing of the raw materials and continuous discharging of the raw materials can be achieved through the discharge blades, the blocking phenomenon is avoided, and the packaging efficiency is high.

Owner:黄斌

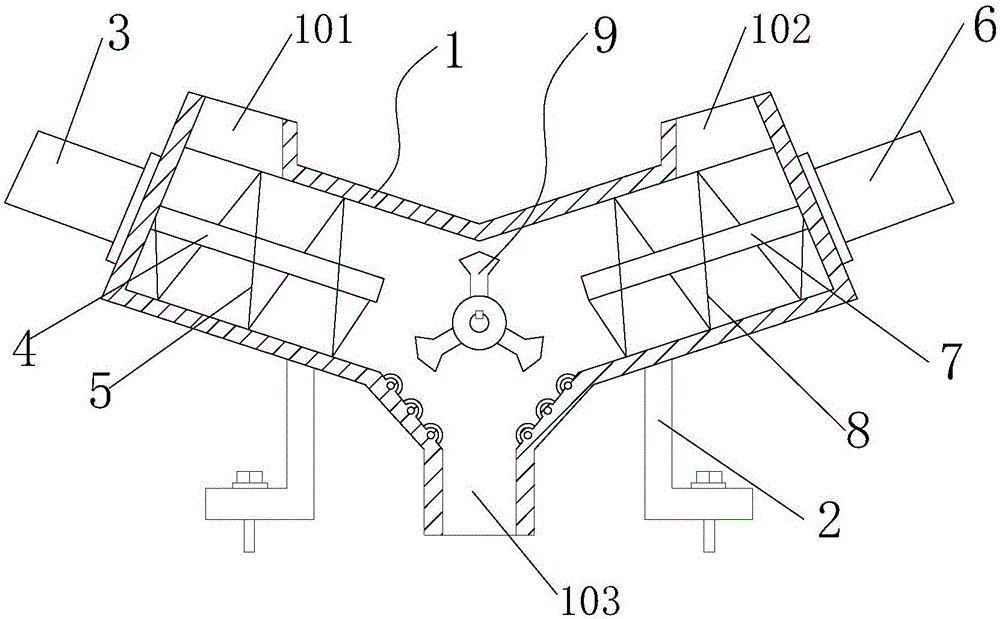

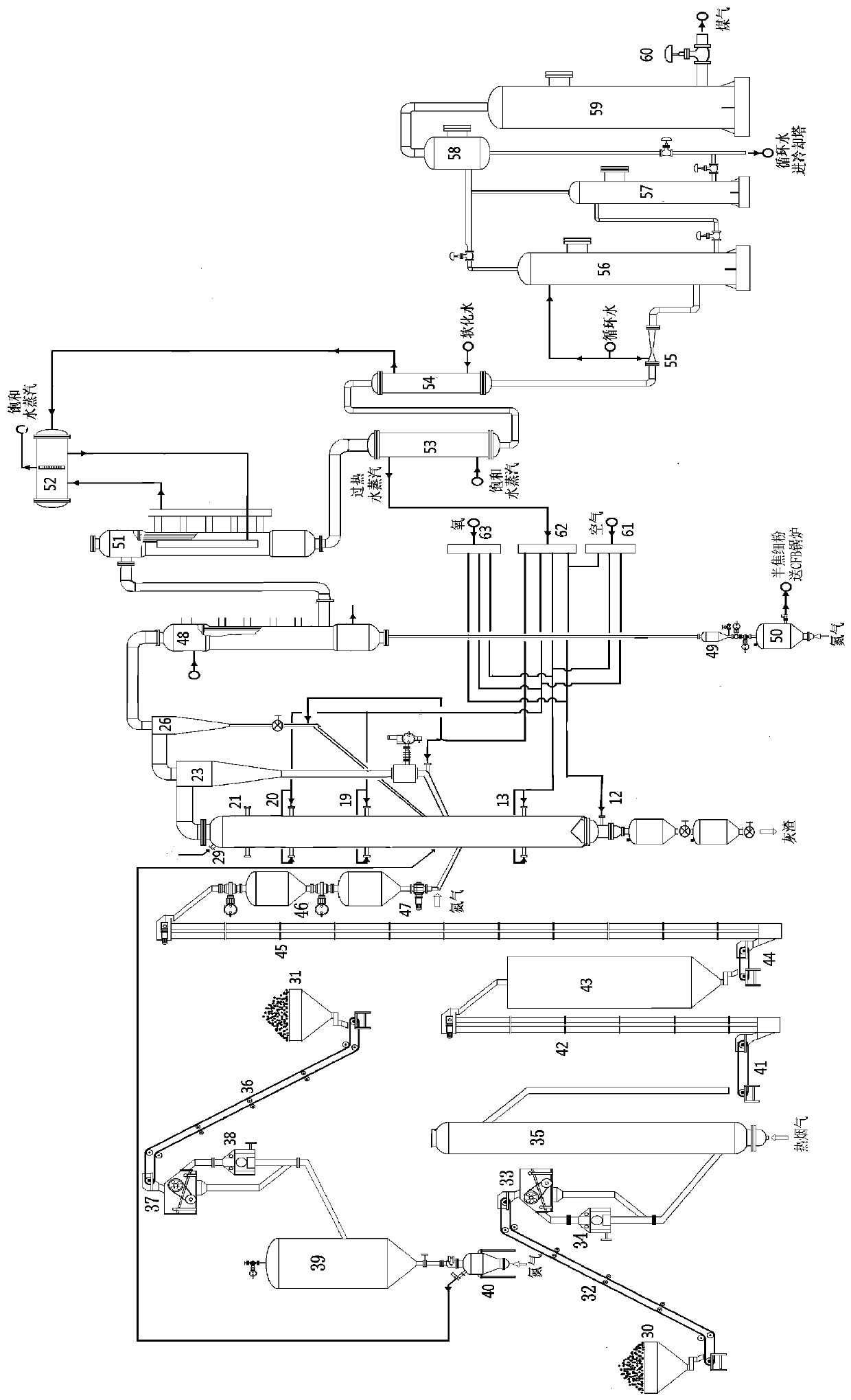

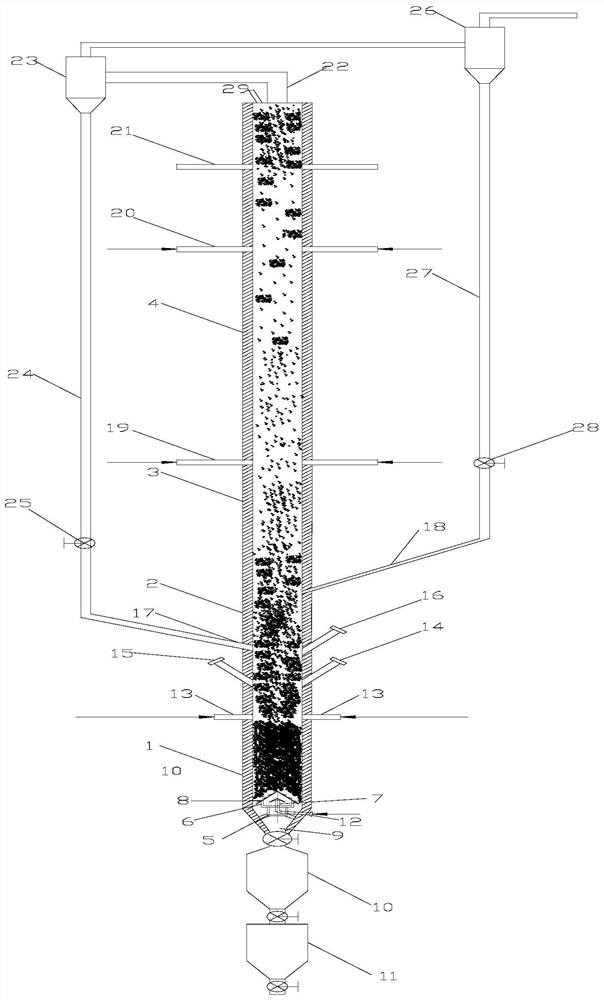

High-temperature fluidized bed reaction device and method of gasifying carbonic material by adopting high-temperature fluidized bed reaction device

ActiveCN109797012AIncrease throughputAchieve near ash melting point operationGranular/pulverulent flues gasificationFluidized bedReaction rate

The invention discloses a high-temperature fluidized bed reaction device and a method of gasifying a carbonic material by adopting the high-temperature fluidized bed reaction device. The device comprises a high-temperature movable bed ash discharging unit, a high-temperature gasification reactor unit and a circular fine semicoke powder conveying unit; the method of gasifying the carbonic materialcomprises the steps of preparation of the carbonic material and sand grains, gas supplying, high-temperature gasification, residue discharging and fine powder conveying. The device and the method havethe advantages that the gasification reaction rate is high, the carbon conversion rate is high, and the treatment capacity of a single furnace is high.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

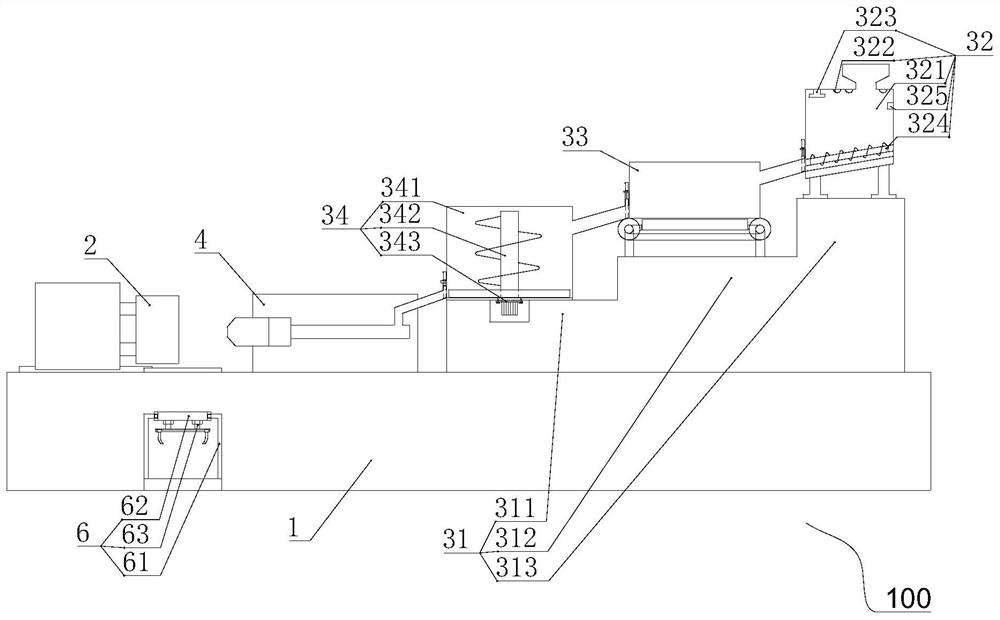

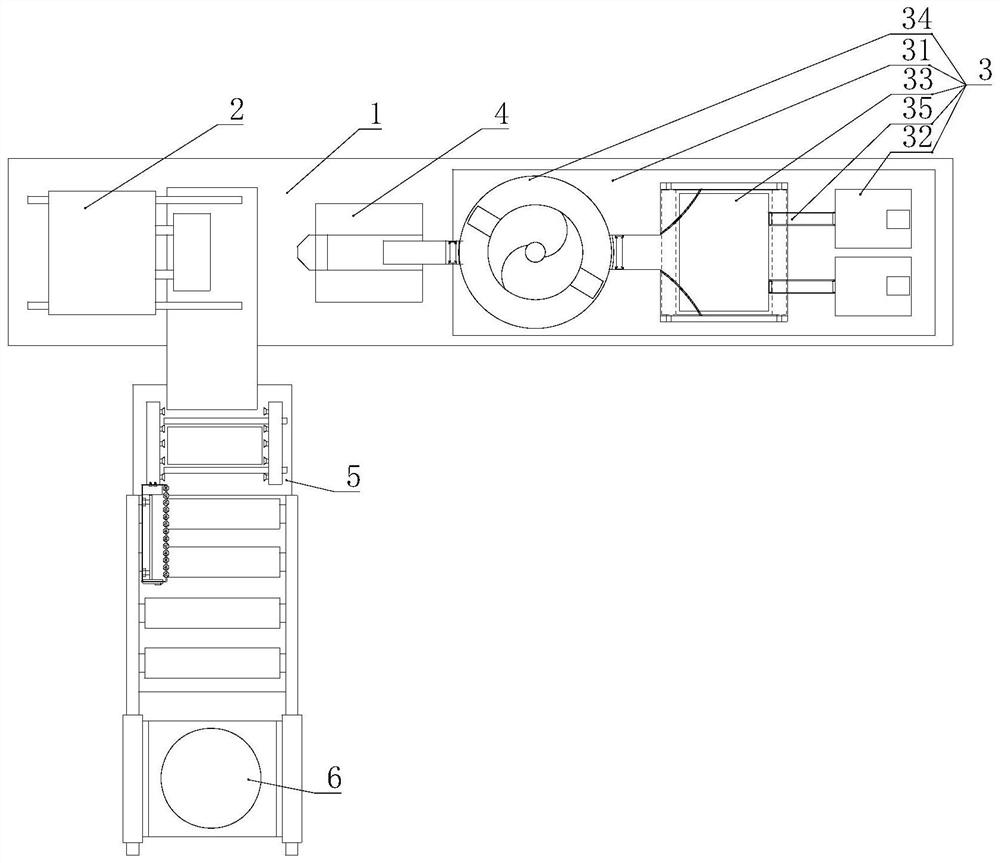

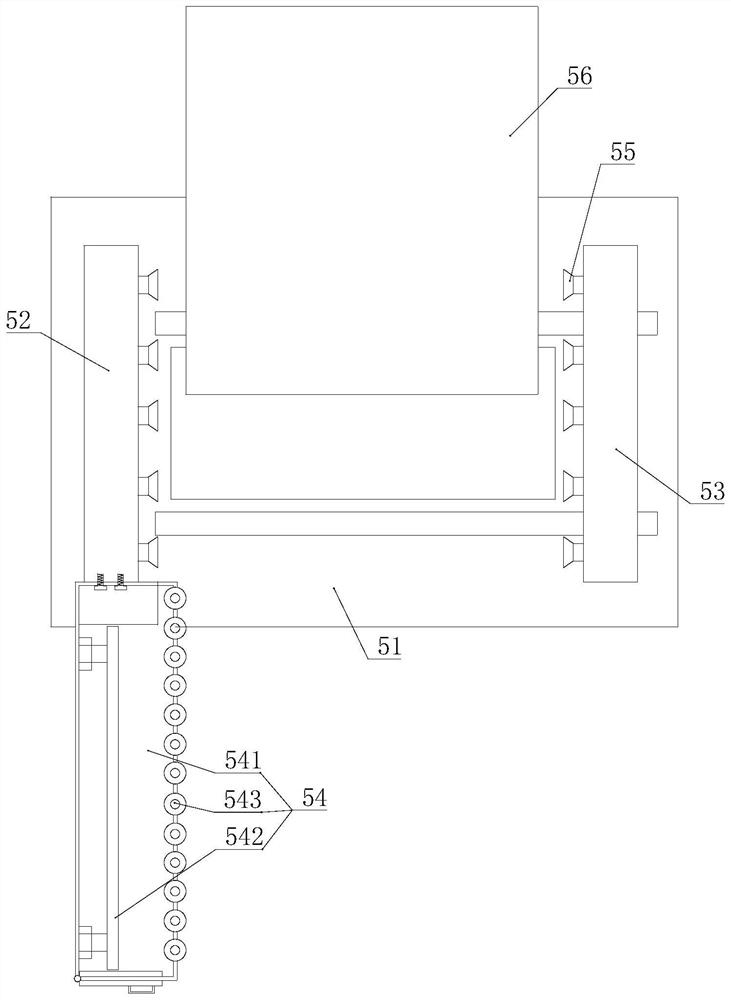

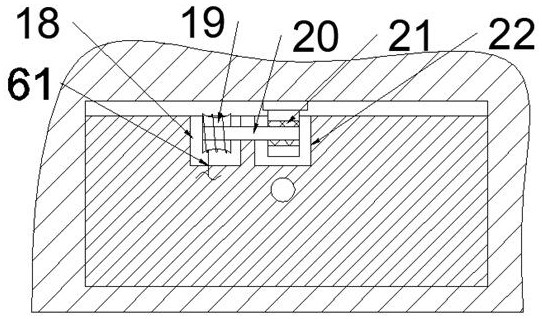

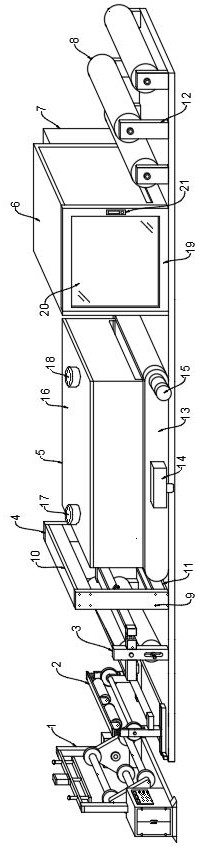

Automatic feeding, packaging and injection molding equipment and application method thereof

The invention discloses automatic feeding, packaging and injection molding equipment and an application method thereof. The automatic feeding, packaging and injection molding equipment comprises a mounting table, an injection mold, an automatic feeding device, an injection component and a receiving device; the injection mold is arranged on one side of the mounting table; the automatic feeding device comprises a mounting step, a dewatering and storing component, a weighing component, a mixing component and a conveying channel; the mounting step is arranged on the other side of the mounting table; the mounting step comprises a first step, a second step and a third step which are arranged from low to high; the mixing component, the weighing component and the dewatering and storage component are sequentially arranged on the first step, the second step and the third step; the injection component is arranged between the injection mold and the automatic feeding device; the receiving device comprises a base, a fixed frame, a movable frame, a bag storage component and a suction cup; the base is arranged on one side of the mounting table; the fixed frame and the movable frame are oppositelyarranged on the two sides of the base; the bag storage component is fixedly arranged on one side of the fixed frame; and the suction cup is arranged on the side, opposite to the movable frame, of thefixed frame.

Owner:太仓市冬鑫塑料制品有限公司

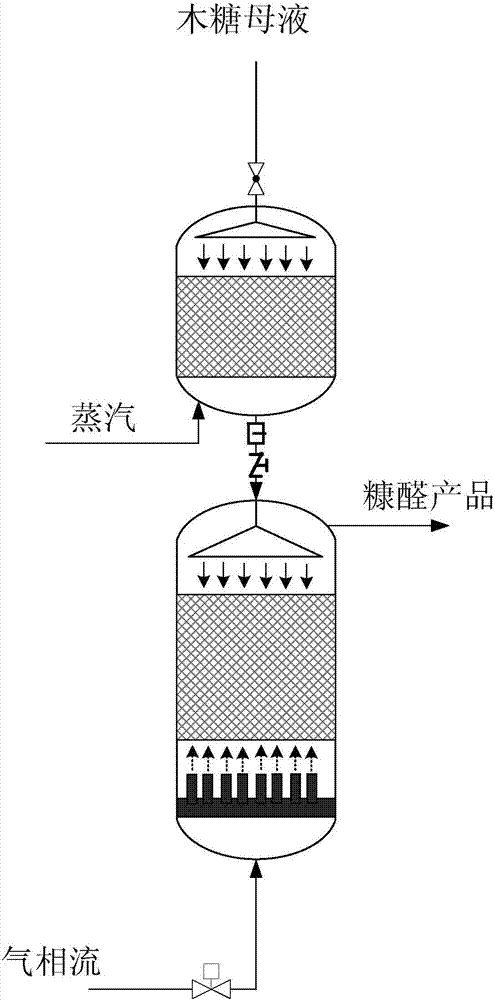

Method for preparing furfural from xylose through dehydration via gas-liquid two-phase flow

InactiveCN107445926AHigh selectivityHigh economic efficiency and environmental benefitsOrganic chemistryXyloseChemistry

The objective of the invention is to provide a method for continuous preparing furfural from xylose. According to the method, a solution containing xylose or xylooligosaccharide is allowed to contact with high-temperature gas-phase flow; and furfural is produced in the process of contact of gas-liquid two-phase flow, is extracted from a liquid phase through stripping via gas flow and then enters gas-phase flow. The method provided by the invention has the advantage that conversion of furfural from xylose and separation of furfural are synchronously carried out; rapid heat transfer and mass transfer enable the selectivity of furfural converted from xylose to be improved; and the yield of furfural is allowed to reach 80% or above of a theoretical conversion rate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

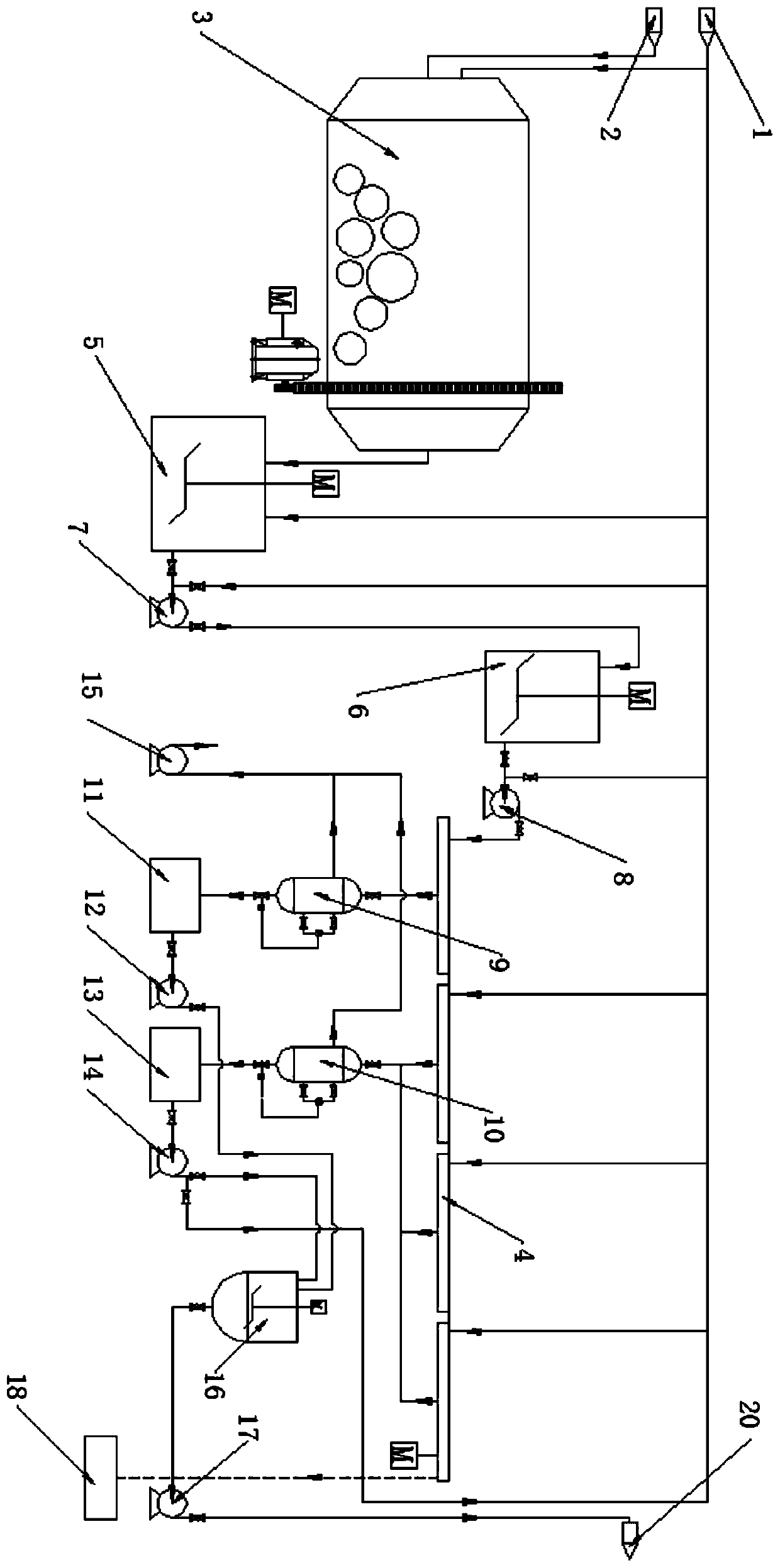

Strontium-barium salt continuous leaching and deslagging production system and production process

InactiveCN110510582ASolve temperature problemsSolve the problem of dustBarium carbonatesStrontium carbonatesHigh concentrationEnvironmental resistance

The invention discloses a strontium-barium salt continuous leaching and deslagging production system, which comprises a ball mill, leaching tanks, a vacuum belt type pumping filter and the like and realizes continuous leaching and deslagging of strontium-barium salt. The invention also discloses a strontium-barium salt continuous leaching and deslagging production process, specifically, a roastedmaterial is added into a recovered strontium-barium salt solution, then grinding is carried out in a ball mill, and a 1# leaching tank and a 2# leaching tank are employed to leach the ground materialstwice, thus solving the severe factors of high temperature, much dust, much water mist and the like at a leaching station; the leached materials are filtered on the vacuum belt type pumping filter interms of a front section and a back section, and a high-concentration strontium-barium salt solution and a low-concentration strontium-barium salt solution with stable concentration can be obtained respectively, and the brine of low-halogen pool is added at the latter half section of the vacuum belt type pumping filter for washing, thus improving the filtering effect, effectively recovering strontium and barium elements, reducing waste, improving the post safety and environmental protection, and eliminating the safety and environmental protection hidden danger of an overall plant area.

Owner:CHONGQING KINGLONG FINE STRONTIUM CHEM

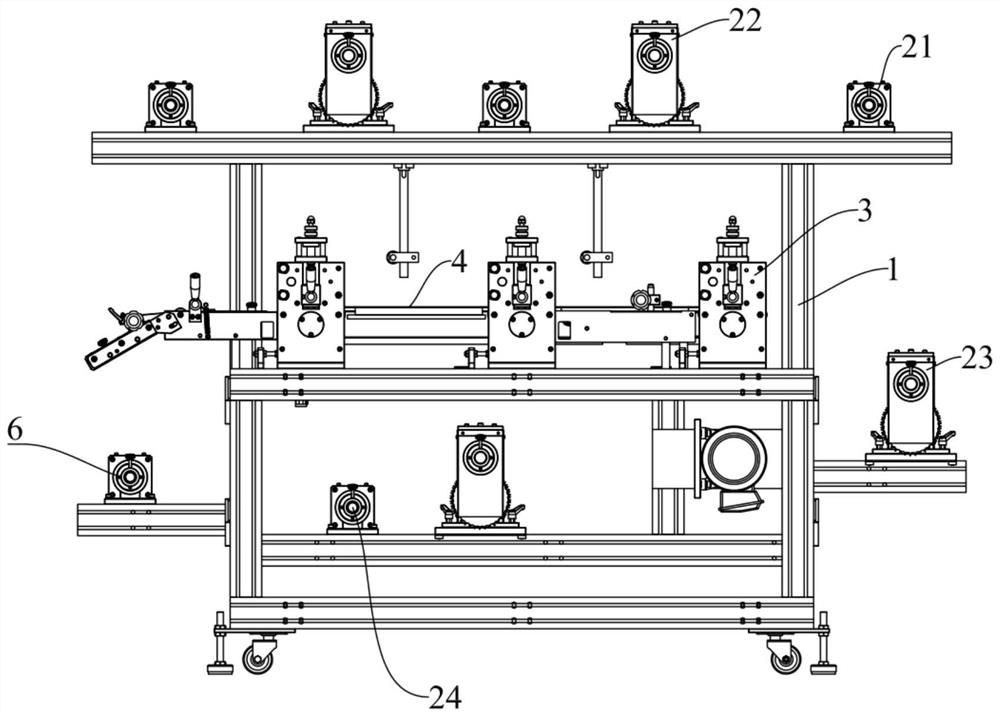

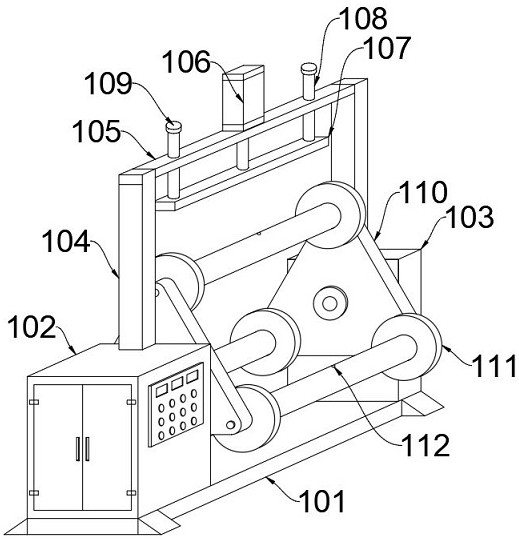

Hot laminating machine and hot laminating method

PendingCN113858628AImprove processing effectReduce the chance of contaminationDomestic articlesManufacturing engineeringIndustrial engineering

The invention discloses a hot laminating machine and a hot laminating method, and belongs to the technical field of electronic product decorating part machining. The hot laminating machine comprises a supporting component, a material receiving and discharging component, a flattening component and a heating component, the material receiving and discharging component comprises a first material discharging part, a first material receiving part and a second material discharging part, the first material discharging part is used for discharging a first material, the first material receiving part is used for winding a first protective film attached to the first material, and the second material discharging part is used for discharging a second material; the flattening component is arranged on the supporting component, and the flattening component is used for flattening the first material and the second material; and the heating component is arranged on the supporting component and located on the downstream of the flattening component, and the heating component is used for heating the flattened first material and the flattened second material and bonding the first material and the second material. The hot laminating machine and the hot laminating method provided by the invention have higher machining efficiency, need fewer operators, and reduce the probability that the first material or the second material is polluted.

Owner:KUNSHAN LIANTAO ELECTRONICS CO LTD

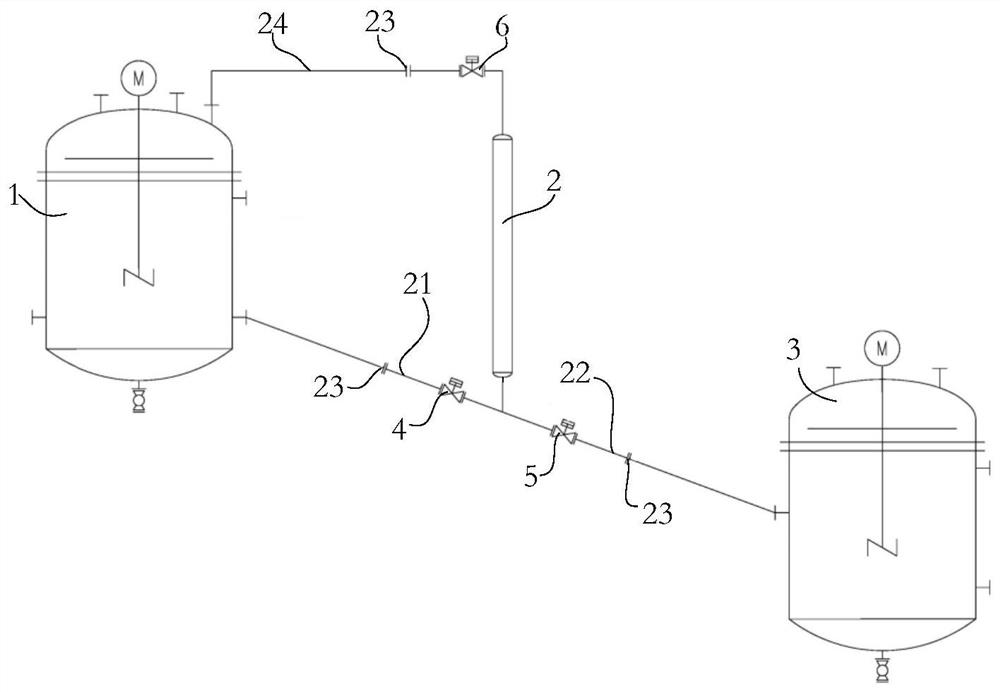

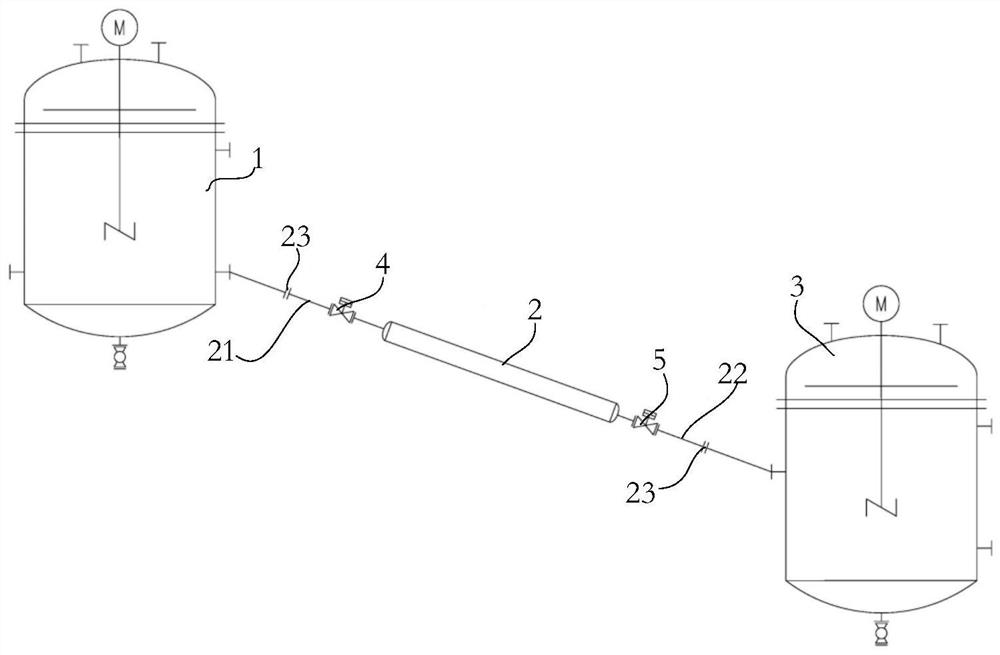

Method of experimental equipment for discharging polyethylene slurry

PendingCN111841449AContinuous dischargeRealize continuous dischargeChemical/physical/physico-chemical stationary reactorsFeed devicesProcess engineeringMechanical engineering

The invention relates to experimental equipment for discharging polyethylene slurry. The experimental equipment comprises a polymerization reaction kettle for storing the polyethylene slurry; a discharging tank which is connected with the polymerization reaction kettle through a feeding pipe, wherein a first valve is mounted on the feeding pipe; a flash tank, wherein the discharging tank is connected with the flash tank through a discharging pipe, and a second valve is installed on the discharging pipe; one end, far away from the polymerization reaction kettle, of each of the feeding pipe andthe discharging pipe extends downwards in an inclined manner; when the first valve is opened, polyethylene slurry is conveyed into the discharging tank by the polymerization reaction kettle under theaction of pressure difference or / and liquid level difference; and when the second valve is opened, the discharge tank conveys the polyethylene slurry into the flash tank under the action of pressure difference or / and liquid level difference. The discharging tank is arranged between the first valve and the second valve, liquid filling and discharging circulation operation is conducted on the discharging tank by switching on and off of the first valve and the second valve, and continuous discharging of slurry in the reaction kettle can be achieved.

Owner:北京拓川科研设备股份有限公司

Optical cable connector device convenient to maintain and capable of preventing water accumulation

InactiveCN112147746ARealize continuous dischargeGuaranteed normal transmissionFibre mechanical structuresMechanical engineeringMaterials science

The invention relates to the related field of optical cables, and discloses an optical cable connector device convenient to maintain and capable of preventing water accumulation. The optical cable connector device comprises a main box body, an optical cable cavity is formed in the main box body, a water accumulation cavity is formed in the lower side of the optical cable cavity in a communicatingmanner, a discharging cavity with a downward opening is formed in the lower side of the water accumulation cavity in a communicating manner, a drainage sliding block cavity is arranged at the right side of the water accumulation cavity, and a clutch cavity is formed in the right side of the drainage sliding block cavity; a drainage lead screw which extends rightwards into the clutch cavity and extends leftwards into the drainage sliding block cavity is connected into the left end wall of the clutch cavity in a running fit manner, a reverse rotation contact switch is fixedly connected to the right end wall of the drainage sliding block cavity, and a drainage sliding block drives a connecting block and a drainage plate to move rightwards through a drainage connecting rod; in cooperation withsteering changes of a motor, continuous drainage of accumulated water is achieved, an optical cable connector box is kept dry, normal transmission of an optical cable is guaranteed, a protection pullrope drives an optical cable connecting disc to slide upwards, the situation that the optical fiber goes wrong due to the fact that too much accumulated water makes contact with the optical cable isavoided as much as possible, and meanwhile the follow-up maintenance workload is reduced; and the workload is reduced.

Owner:深圳市云陌科技有限公司

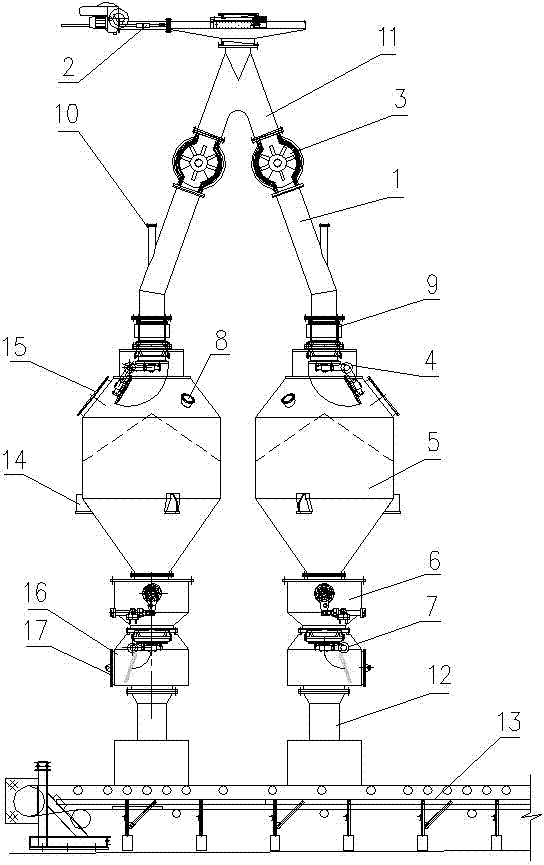

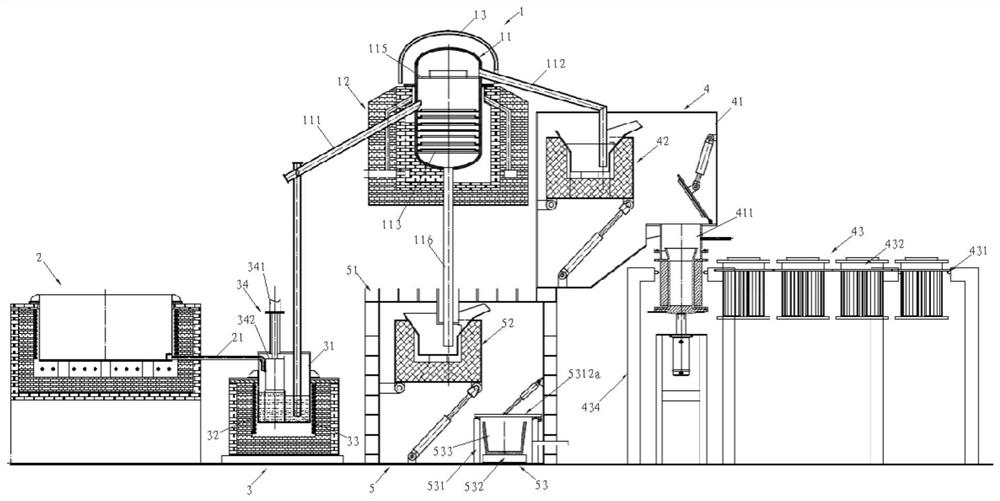

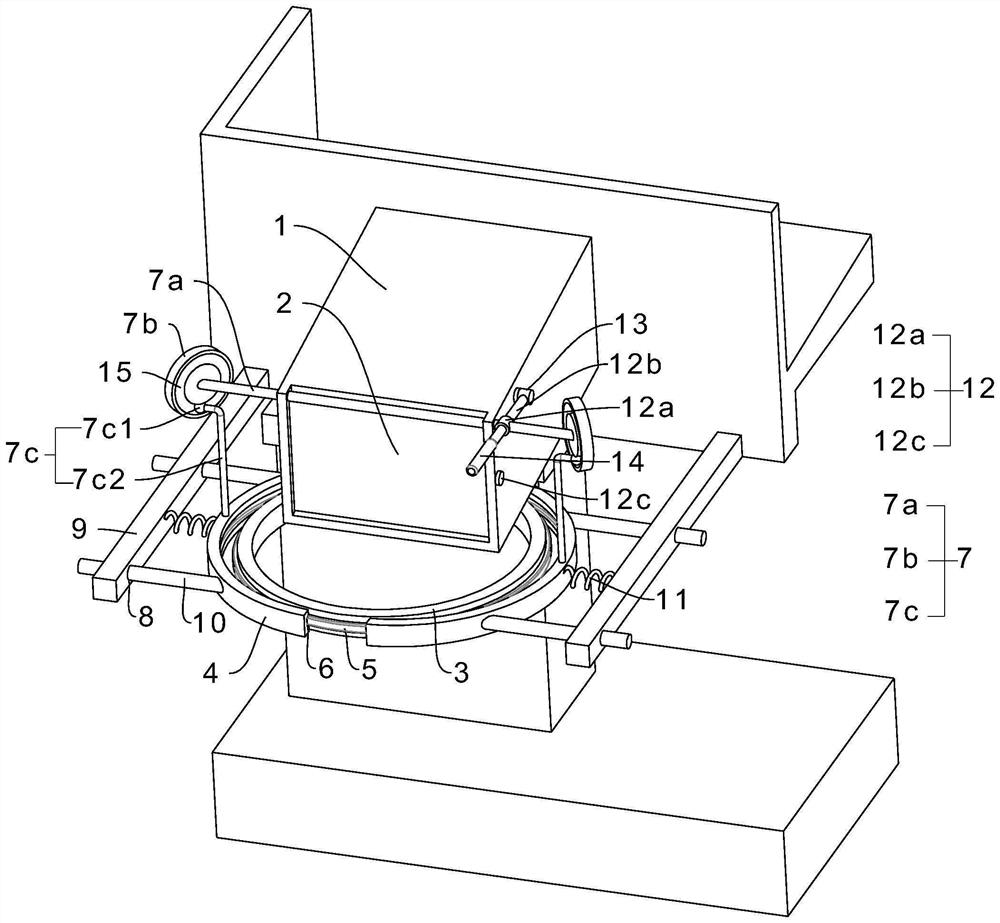

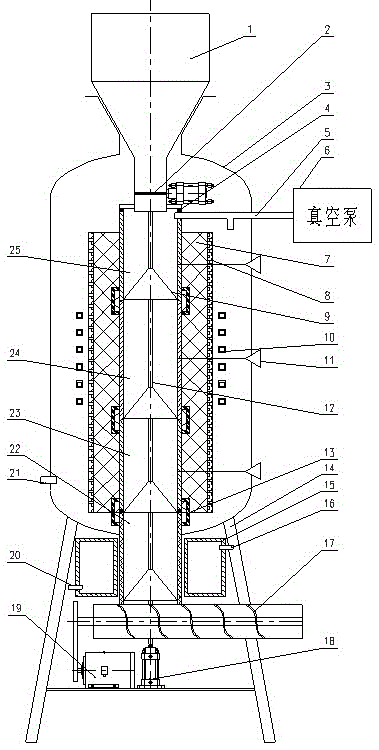

Vacuum distillation and forming device and method for extracting metal calcium from carbide slag

PendingCN113265550AImprove distillation efficiencyIncrease productivityIngot casting plantsProcess efficiency improvementSlagCarbide

The invention relates to a vacuum distillation and forming device and method for extracting metal calcium from carbide slag. The vacuum distillation device comprises a vacuum calcium distillation furnace (11) and a heating furnace seat (12) for mounting the vacuum calcium distillation furnace (11); a part of the vacuum calcium distillation furnace (11) is covered with a cooling device (13), and the rest part of the vacuum calcium distillation furnace (11) is positioned in the heating furnace seat (12); and the cooling device (13) is positioned above the heating furnace seat (12). The vacuum distillation device is high in distillation efficiency, and the production efficiency of refined calcium is greatly improved.

Owner:鄂尔多斯市欣欣宸瑞高纯材料有限公司

Efficient discharging mechanism and screening equipment for pinellia ternate processing

ActiveCN114101031AEasy to operateRealize continuous dischargeSievingScreeningPinellia tuberiferaMachine

The invention relates to the technical field of screening equipment, and discloses an efficient discharging mechanism and screening equipment for processing pinellia ternata, the efficient discharging mechanism comprises a discharging barrel with a rectangular longitudinal section, a discharging door capable of being opened and closed, a fixing frame and two clamping frames, the fixing frame is used for fixing a material containing bag, and the cross section of the fixing frame is round or oval; a limiting ring is arranged in the middle of the outer side of the fixing frame, a limiting groove is formed in the middle of the inner side of each clamping frame, and the driving assembly simultaneously drives the two clamping frames to be pressed on the outer side of the fixing frame and drives the discharging door to be opened or closed. The driving assembly is arranged, the clamping frame can be driven to be pressed on the outer side of the fixing frame and the discharging door can be driven to be opened or closed at the same time, discharging can be achieved only by correspondingly operating the driving assembly, the bag opening of the flexible bag does not need to be continuously held by hands, and operation is rapid, easy and convenient; and when a new flexible bag needs to be replaced, the machine does not need to be stopped, continuous discharging is achieved, and the discharging efficiency is high.

Owner:潜江市潜半夏药业股份有限公司

High-temperature fluidized-bed reaction device and method for gasifying carbon-containing materials thereof

ActiveCN109797012BIncrease throughputAchieve near ash melting point operationGranular/pulverulent flues gasificationFluidized bedReaction rate

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A self-heating straw carbonization furnace

ActiveCN102533291BReduce consumptionReduce lossesBiofuelsSpecial form destructive distillationCombustion chamberFlue gas

The invention relates to a carbonization device, in particular to a self-circulation heating straw carbonization furnace, solving the problems of the existing carbonization device that combustible components in crops cannot be discharged completely to be utilized and a large amount of fuel is needed to provide heat for carbonization. The device comprises a carbonization chamber, and the carbonization chamber is provided with a feeding port and a discharging port. The device is characterized in that the carbonization chamber is internally provided with an inner combustion chamber, an outer combustion chamber is arranged around the outer side of the carbonization chamber, smoke exhaust holes are respectively arranged between the carbonization chamber and the inner combustion chamber and between the carbonization chamber and the outer combustion chamber, the inner combustion chamber and the outer combustion chamber are respectively provided with an air inlet and an air outlet, and the inner combustion chamber or the outer combustion chamber is also connected with a startup heater to provide heat for startup. Combustible flue gas produced in decomposition can be led out for combustion during carbonization, and the fuel consumption can be reduced; hot air exhaust of the carbonization furnace can be used as material delivery airflow to preheat materials, and the energy loss can be reduced; and the internal and external simultaneous circulation and heating can be realized due to the arrangement of the inner combustion chamber and the outer combustion chamber, and the rate of utilization of circulating energy is high.

Owner:ZHEJIANG BULAIMENG AGRI SCI & TECH

Ultra-fine dynamic classification discharge device of dry ball mill system

ActiveCN106334601BImprove quality uniformityRealize continuous dischargeGrain treatmentsEngineeringUltra fine

The invention relates to a dry type ball-milling system and particularly relates to a superfine dynamic graded discharge device for a dry type ball-milling system. The device comprises a hollow cylinder with a discharge port at the bottom end. The discharge port is connected to a discharge mechanism, and materials flowing from the discharge port of the cylinder flow out through the discharge mechanism; the discharge mechanism comprises a base body which is hermetically connected to the discharge port and a discharge wheel which is arranged in the base body and is driven by a motor to rotate, and the materials flowing into the base body from the discharge port are driven by the discharge wheel which rotates to flow out. According to the device provided by the invention, outside gas is inhaled into the graded cylinder by using a negative pressure device. The gas can be used for graded treatment on materials which are relatively light in the graded cylinder and materials which are relatively heavy in the graded cylinder, so that a purpose of improving the quality uniformity of a finished product is achieved; meanwhile, the discharge mechanism is arranged at the discharge port, so that continuous discharge can be realized, and the discharge port can be sealed during feeding at a negative pressure, and therefore, the airtightness in the negative pressure state is guaranteed.

Owner:PUHLER GUANGDONG SMART NANO TECH CO LTD +2

A two-way piston pump and its control method

ActiveCN106523318BUniform dischargeRealize continuous dischargePositive displacement pump componentsPump installationsReciprocating motionControl system

The invention is suitable for the field of piston pumps, and provides a two-way piston pump and a control method thereof. The piston pump comprises a control system, a first one-way metering pump, a second one-way metering pump, a first driving mechanism and a second driving mechanism; the control system controls operation or standing of the first and second driving mechanisms; the first and second one-way metering pumps are respectively connected with the first and second driving mechanisms; each one-way metering pump has a hollow cavity, a sucking port and a discharge port; the cavity is communicated with the sucking port and the discharge port; a pneumatic ball valve is mounted in the sucking port; a one-way valve is mounted in the discharge port; each driving mechanism includes a piston rod capable of extending; the end parts of the piston rods are inserted in the cavities of the one-way metering pumps, and perform a reciprocating motion in the cavities; and the control system controls the first and second driving mechanisms to drive reverse movement of the two piston rods. The piston pump has two sets of one-way piston metering pumps; one set is for feeding, and the other set is for discharging; and the two sets are alternately operated to realize continuous discharge of the piston pump.

Owner:SHENZHEN SECOND INTELLIGENT EQUIP CO LTD

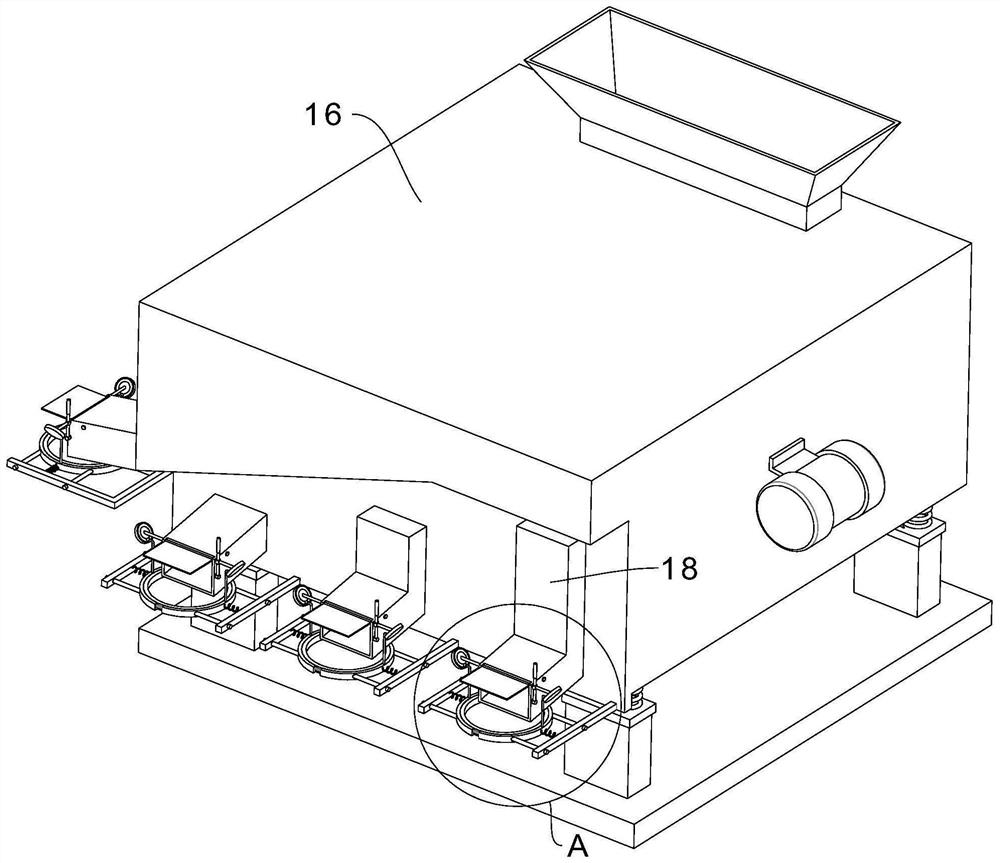

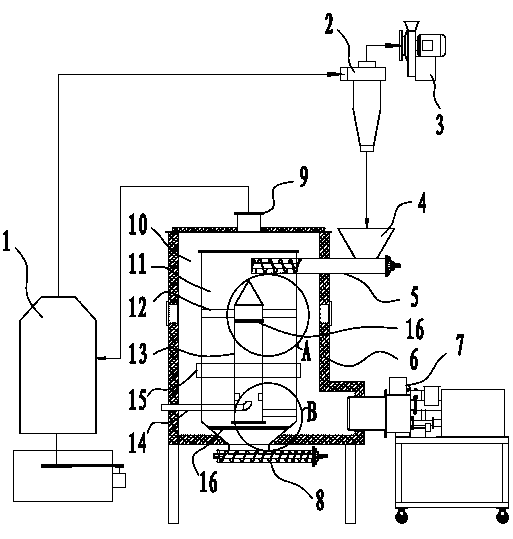

Device and method used for killing African swine fever viruses in feedstuffs

PendingCN111248395ALow costQuick kill treatmentFood preservationAfrican swine feverAfrican swine fever virus

The invention provides a device and method used for killing African swine fever viruses in feedstuffs. According to the characteristic that the tolerance of the African classical swine fever viruses to heat is weak, hot air with relatively high temperature is utilized to heat the feedstuffs to certain temperature and heat preservation is performed for a certain period of time, and thus, the African classical swine fever viruses possibly present in the feedstuffs are quickly killed, and the operation of killing the African swine fever viruses can be rapidly implemented on the feedstuffs in timebefore the feedstuffs are delivered or after the feedstuffs arrive at the transportation destination. The device and the method have the characteristics of high feedstuff handling capacity, continuous handling process and low virus killing cost.

Owner:ZHENGZHOU WANGU MACHINERY

A vertical continuous induction high temperature graphitization furnace

The invention discloses a vertical continuous induction type high-temperature graphitization furnace. The graphitization furnace comprises a furnace body shell, a hopper positioned above the furnace body shell, and a discharging pipe positioned at the bottom of the furnace body shell, wherein the hearth inside the furnace body shell is divided into four areas from top to bottom, namely a preheating area, a heating area, a temperature reducing area and a cooling area; every two adjacent areas are communicated with each other or isolated from each other by a corresponding isolating material part having an opening and closing function; a discharging port of the hopper is connected with a feeding hole of the preheating area by a valve; a heat insulating layer is arranged in the peripheral direction of the outer wall of the hearth; a heater is arranged between the inner wall of the shell and the heat insulating layer segment outside the heating area; a cooling system is arranged outside the discharging pipe so that the cooling area is formed inside the discharging pipe. The graphitization furnace disclosed by the invention has the advantages of greatly increasing the yield and quality of a graphitized material, satisfying the technological requirements of thermal treatment of a cathode material of a power battery and improving the quality of the battery.

Owner:湖南烁科热工智能装备有限公司

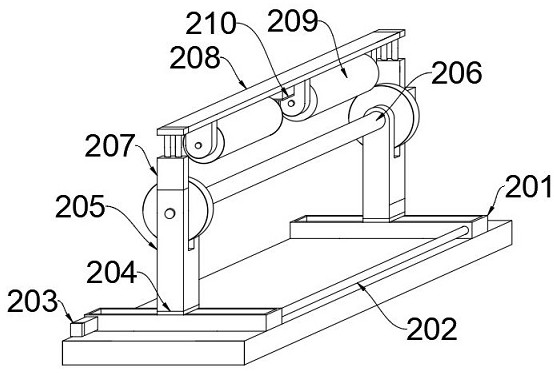

A high-uniform quantitative coating device and coating method for moisture-proof and folding-resistant packaging aluminum foil paper

ActiveCN114308522BConsistent timeConsistent thicknessPretreated surfacesCoatingsDust controlAluminum foil

The invention discloses a high-uniform quantitative coating device and a coating method for moisture-proof and folding-resistant packaging aluminum foil paper, relates to the technical field of cigarette package aluminum foil paper processing, and aims to solve the problem of the coating device used in the existing tobacco packaging aluminum foil paper, coating head Some of them are driven by guide rails, and the way of moving left and right to realize the feeding of rubber rollers is prone to uneven coating, which will affect the quality of products. One side of the three-station unwinding mechanism is provided with a material receiving mechanism, one side of the material receiving mechanism is provided with a coating mechanism, one side of the coating mechanism is provided with a laser thickness measuring mechanism, the laser measuring Both sides of the thickness mechanism are provided with laser curtain brackets, a laser curtain transmitter is installed above the laser curtain brackets on both sides, a laser curtain receiver is installed under the laser curtain brackets on both sides, and the laser thickness measuring mechanism One side of the belt-type pre-drying mechanism is provided with a drying and dust-removing mechanism.

Owner:汕头市强宇包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com