Fluidized bed reactor

A fluidized bed reactor and separator technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problem that the production rate of aluminum sulfate or aluminum ammonium sulfate is not high, the roasting time cannot be satisfied, and the equipment has high corrosion resistance requirements. problems, to achieve the effect of less particle damage, long operation cycle and stable quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

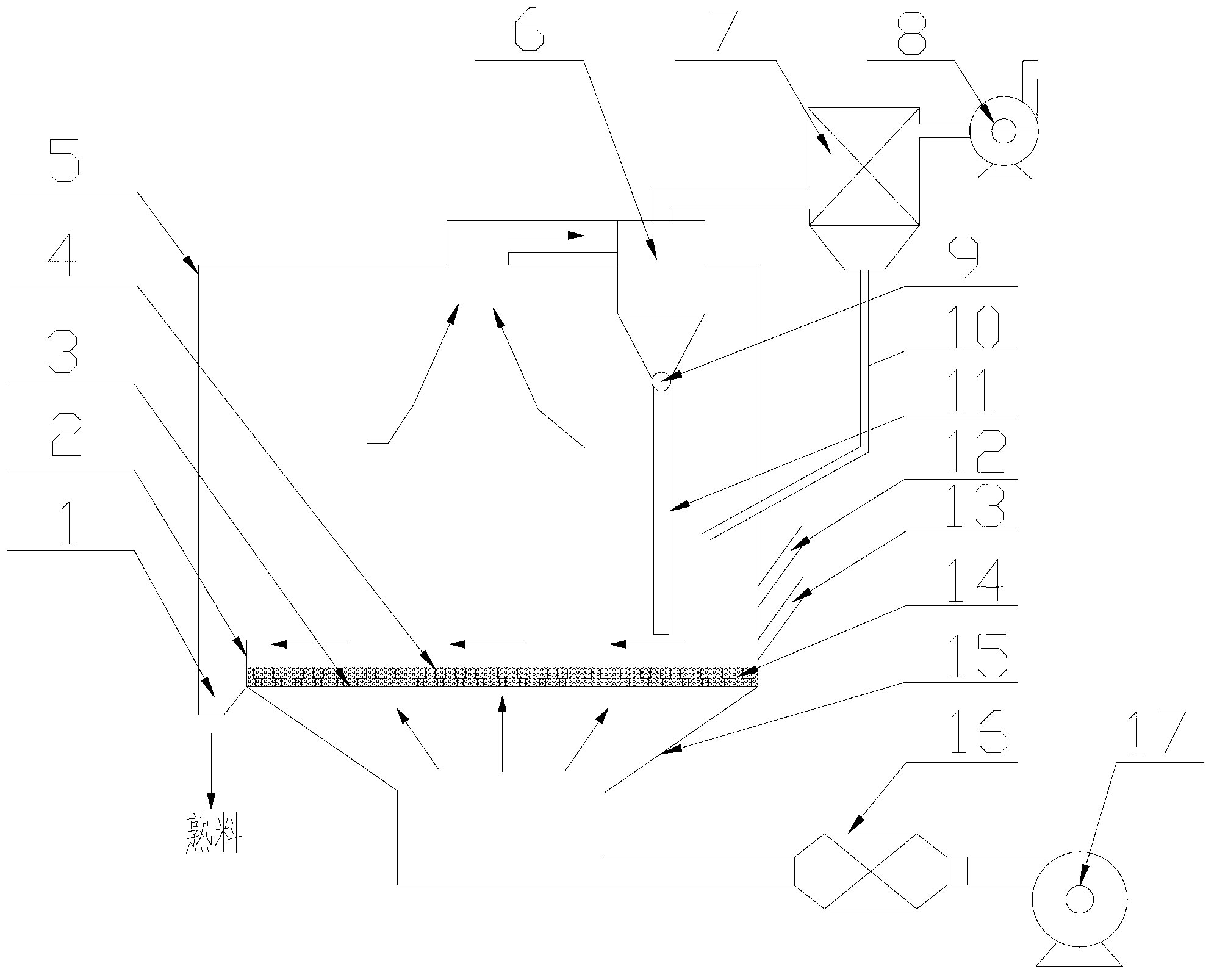

[0024] As shown in the drawings, a fluidized bed reactor of the present invention includes a shell 5, and a horizontal air distribution plate 3 that carries materials and meets the requirements of fluidized air distribution is arranged inside the shell 5. The air distribution plate 3 is arranged The air cap 4, the air cap 4 can be a bell type air cap, a T-shaped air cap or a directional air cap. Below the air distribution plate 3 is the air chamber 15, the air chamber 15 is connected to the outlet of the air preheater 16, the air preheater 16 is connected to the blower 17, and the blower 17 provides fluidized air; The separator 6 is used for material separation of the flue gas, and the separated material re-enters the reactor for reaction. The built-in separator 6 can prevent the material from sticking at low temperature. The inlet of the separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com