Ultra-fine dynamic classification discharge device of dry ball mill system

A dynamic grading and discharging device technology, which is applied in grain processing and other directions, can solve the problems of uneven product particle size, negative pressure feeding air tightness, etc., achieve continuous discharging, improve quality uniformity, and ensure air tightness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

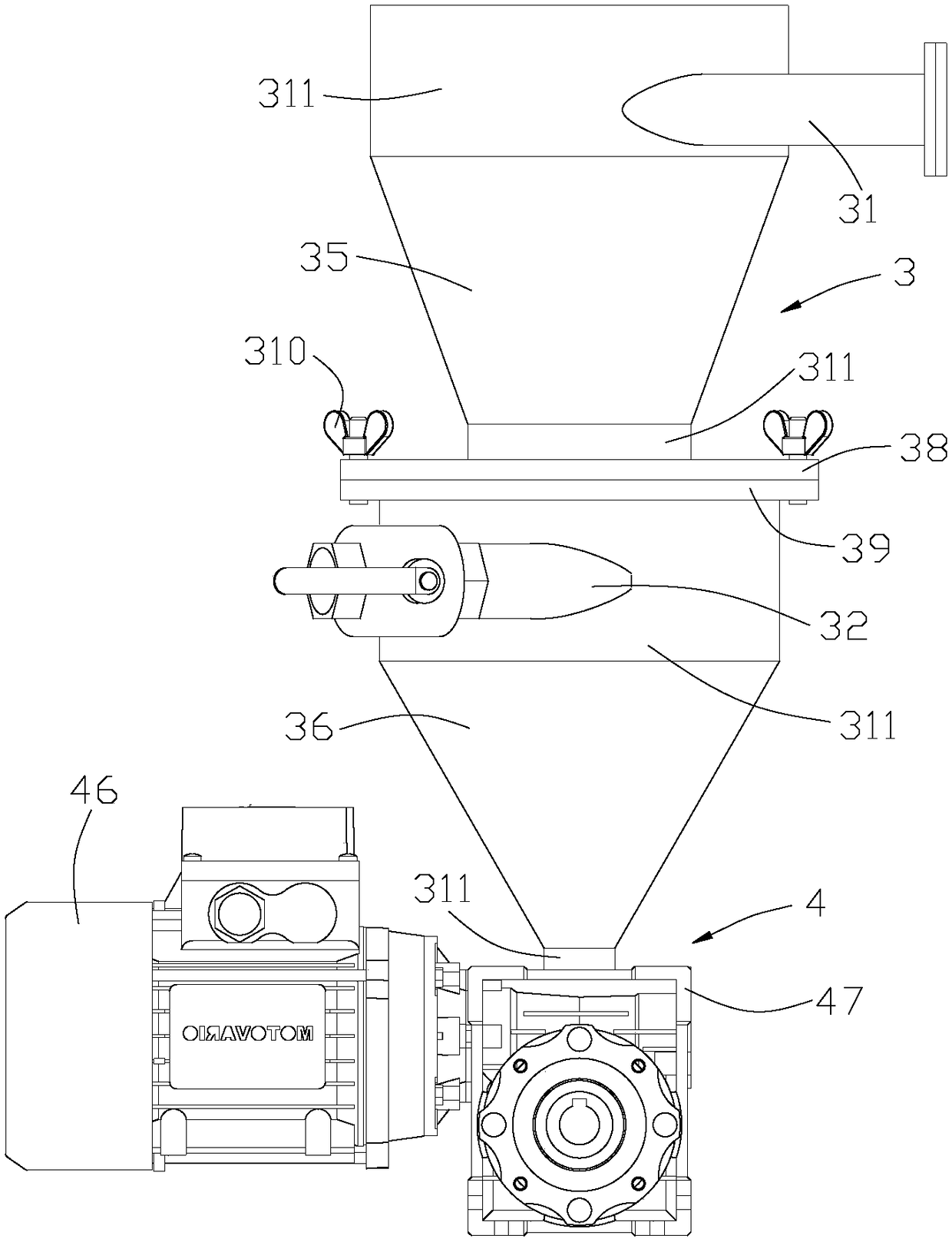

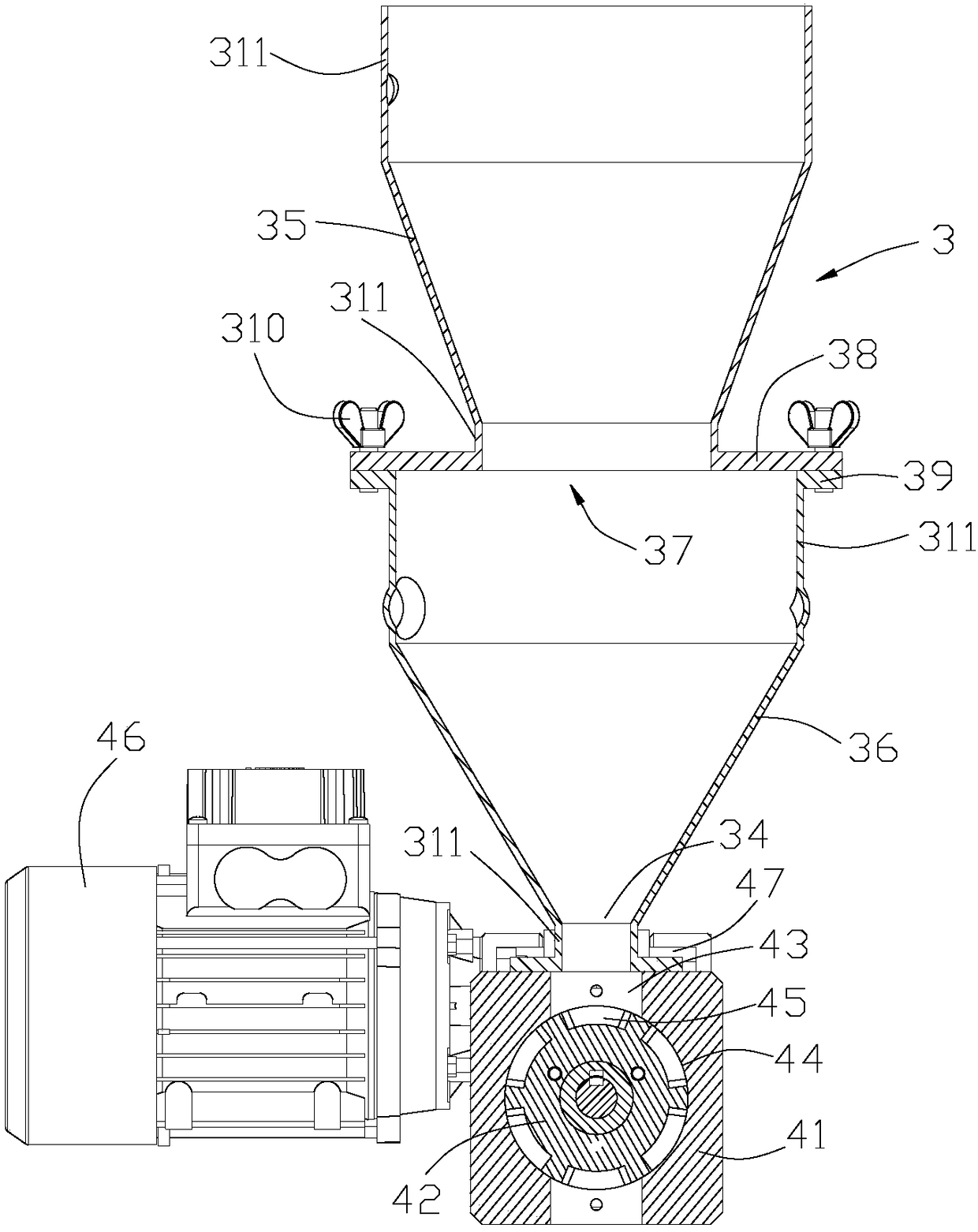

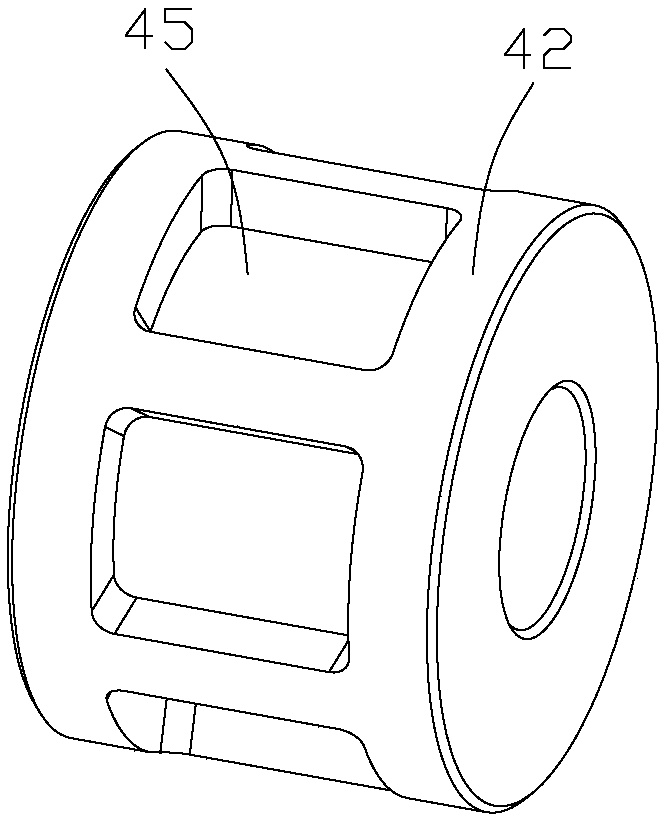

[0019] Combine below figure 1 , figure 2 and image 3 Introduce the present invention in detail:

[0020] The ultra-fine dynamic classification discharge device of the dry ball mill system comprises a hollow cylinder 3 with a discharge port 34 at the bottom, and a feed pipe 31 for the material to enter the inner cavity of the cylinder is provided on the upper part of the cylinder. The present invention The material is not limited to the material after ball milling, raw material powder can also be used; the lower part of the cylinder is provided with an air inlet pipe 32 for the gas to enter the inner cavity of the cylinder, and the negative pressure device arranged at the top of the cylinder makes the outside air flow from the The air inlet pipe 32 enters the inner cavity of the cylinder, and the gas entering the inner cavity of the cylinder blows the lighter materials in the inner cavity from bottom to top to the top of the cylinder and then flows out, and the heavier mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com