High-temperature fluidized-bed reaction device and method for gasifying carbon-containing materials thereof

A high-temperature fluidized bed and high-temperature technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. problems, to achieve the effects of high single furnace processing capacity, high carbon conversion rate, and fast gasification reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

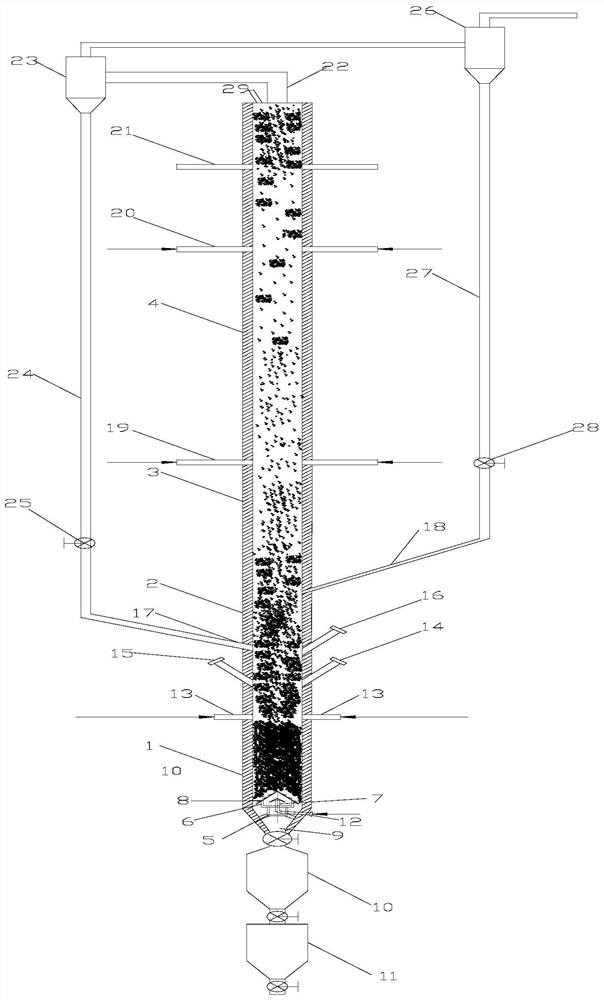

[0044] The high-temperature fluidized-bed gasification furnace of the present invention includes three units: a high-temperature moving bed ash discharge unit, a high-temperature gasification reactor unit, and a semi-coke fine powder circulation conveying unit;

[0045] The high-temperature moving bed ash discharge unit consists of a moving bed ash discharge circular furnace body 1, a bottom support body 5, a middle rotating support body 6, a central pipe 7, a rotating ash discharge furnace pan 8, an ash discharge port 9, an upper row It consists of a slag hopper 10, a lower slag discharge hopper 11, and a gasification agent inlet pipe 12. The bottom support body 5 is located at the bottom of the moving bed ash discharge circular furnace body 1. The bottom support body 5 is fixed with a central pipe 7, which is located at the bottom support On the vertical center line of the body 5, the inlet of the central pipe 7 is connected to one end of the gasification agent inlet pipe 12 ...

Embodiment 2

[0068] The diameter of the circular furnace body of the high-temperature gasification reactor unit is D and the height is H; the diameter of the moving bed ash discharge circular furnace body 1 is D and the height is 0.05H.

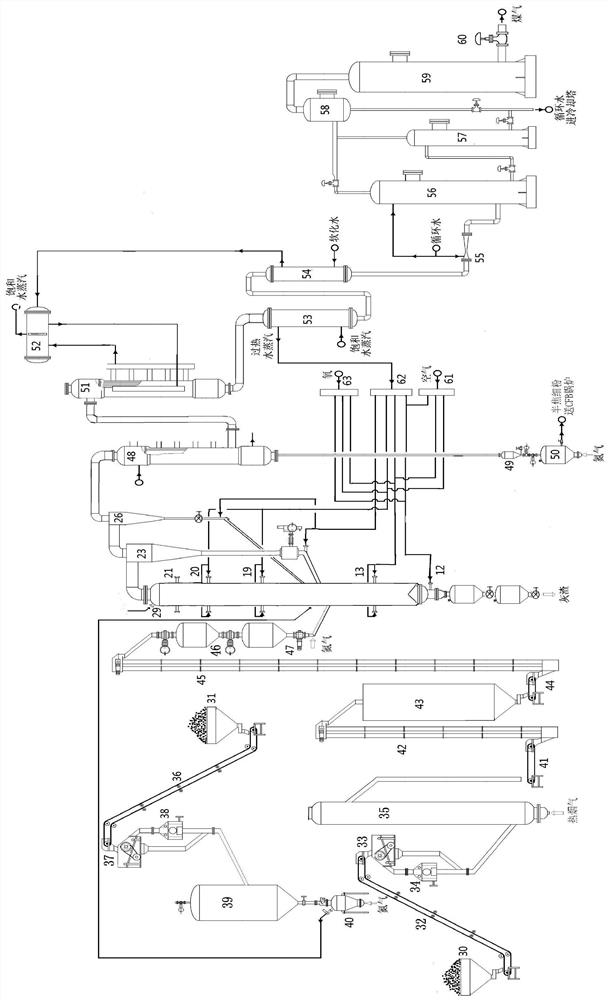

[0069] The raw material for gasification is Wenshan lignite in Yunnan, the coal feed rate is 2600Kg / h, and the oxygen feed rate is 1600Nm 3 / h, the water vapor intake is 2500Kg / h, the sand intake is 24Kg / h, the pressure of the gasifier is controlled at 1.0MPa, the temperature of the lower part 2 of the circular furnace body is stable at 950°C, and the gasification agent inlet pipe in the middle of the circular furnace body 19 Introduce 155Nm3 / h of oxygen and 50Kg / h of steam to maintain the temperature of the middle part 3 of the circular furnace body at 980°C, and 77Nm of oxygen into the upper gasification agent inlet pipe 20 of the circular furnace body 3 / h and steam rate 41Kg / h, maintain the temperature of circular body of heater top (4) at 950 ℃, all ...

Embodiment 3

[0071] The diameter of the circular furnace body of the high-temperature gasification reactor unit is D and the height is H; the diameter of the moving bed ash discharge circular furnace body 1 is D and the height is 0.15H.

[0072] The gasification raw material is Jincheng anthracite, the coal input is 3000Kg / h, and the oxygen input is 2100Nm 3 / h, the water vapor intake is 3500Kg / h, the sand intake is 38Kg / h, the pressure of the gasifier is controlled at 1.5MPa, the temperature of the lower part 2 of the circular furnace body is stable at 1200 °C, and the gasification agent is fed into the middle of the circular furnace body The amount of oxygen fed into the trachea 19 is 190Nm 3 / h and steam volume 61Kg / h, maintain the temperature of the middle part 3 of the circular furnace body at 1125°C, and the gasification agent inlet pipe 20 in the upper part of the circular furnace body is fed with an oxygen volume of 95Nm 3 / h and steam rate 51Kg / h, maintain the temperature of circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com