Chlorcosane tail gas absorption technology and equipment

A technology for chlorinated paraffin and tail gas absorption, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of high labor intensity, poor control of hydrochloric acid concentration, etc., and achieve the effect of ensuring stability

Inactive Publication Date: 2010-08-25

LIAOCHENG LUXI CHEM ENG DESIGN

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Disadvantages of the process: when the dilute acid reaches a certain concentration, the circulation absorption must be stopped, the absorption process is intermittent operation, the labor intensity is high, and the concentration of hydrochloric acid is not easy to control

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

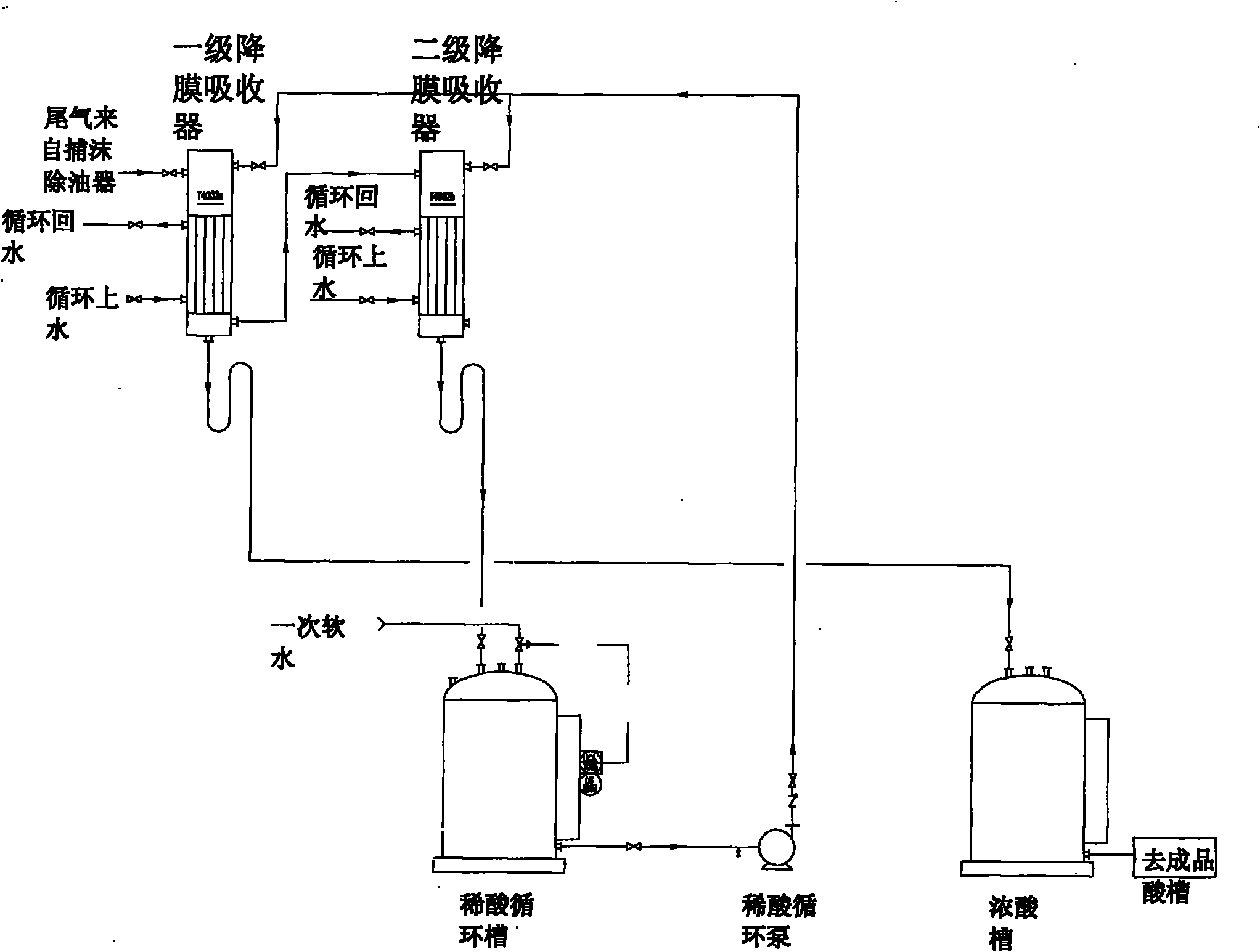

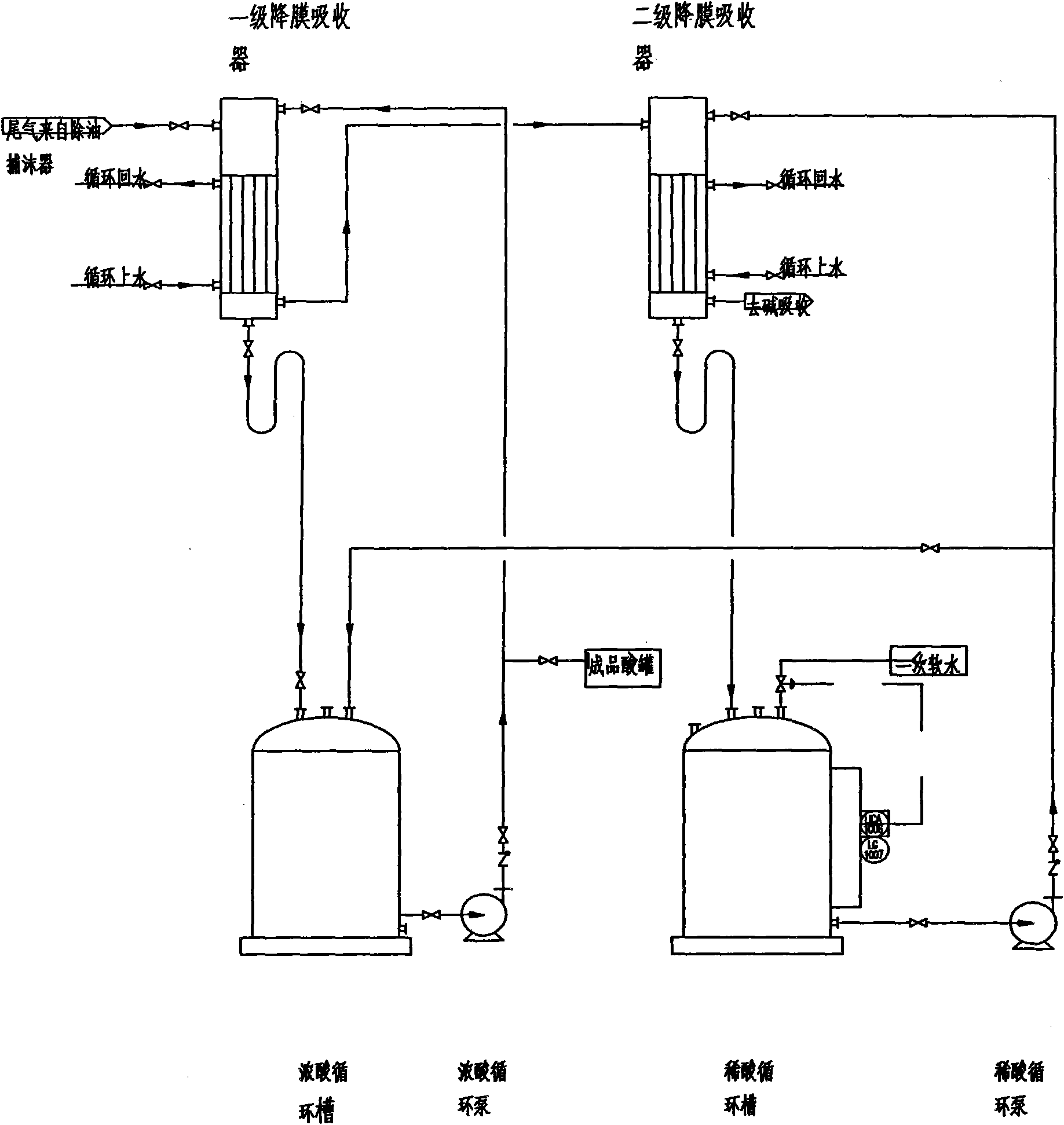

The invention relates to a chlorcosane tail gas absorption technology and equipment. Chlorcosane tail gas firstly enters a first-grade falling film absorber; after adsorbing hydrogen chloride gas, the first-grade falling film absorber recovers finished product acid and then the recovered finished product acid enters a concentrated acid slot, and residual hydrogen chloride gas enters a secondary-grade falling film absorber; dilute acid can be obtained after being adsorbed by the secondary-grade falling film absorber; recovered dilute acid enters into a dilute acid circulating slot; dilute acid in the dilute acid circulating slot is sent out by the dilute acid circulating pump, parts of dilute acid enter a secondary-grade falling film absorber for cycle absorption, and other parts enter the first-grade falling film absorber and are absorbed and then enter the concentrated acid slot. Compared with the prior art, the invention saves one concentrated acid circulating pump, realizes continuous discharging of finished acid and ensures the stability of acid concentration.

Description

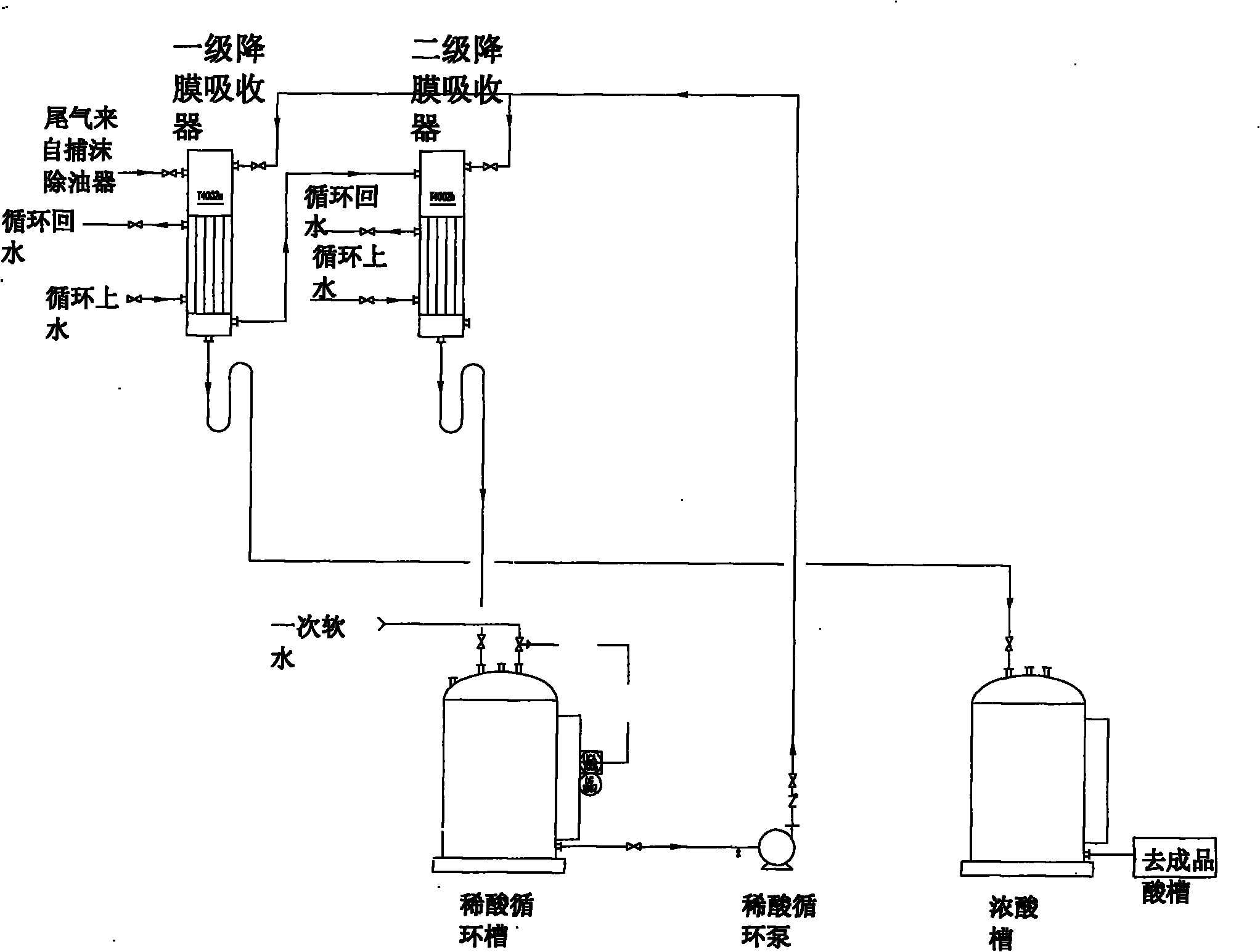

Chlorinated paraffin tail gas absorption process and equipment Technical field: The invention relates to the treatment of tail gas in a chlorinated paraffin device, in particular to a process and equipment for absorbing the tail gas of chlorinated paraffin. Background technique: The tail gas produced by the chlorinated paraffin plant is mainly hydrogen chloride gas. Some domestic chlorinated paraffin manufacturers send this part of the tail gas into the hydrochloric acid synthesis furnace for combustion. The original tail gas absorption (acid absorption) process (see Figure 1) is: The exhaust gas enters the first and second falling film absorbers successively. The first falling film absorber absorbs 60-70% hydrogen chloride gas, and the second falling film absorber absorbs 30-40% hydrogen chloride gas to form concentrated acid and dilute acid respectively. Each is cyclically absorbed, and the acid used as the circulating liquid part is replenished with one-time water. After th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/18

Inventor 牛军张雷李方臣孙富新管艳华谢培建闫志强

Owner LIAOCHENG LUXI CHEM ENG DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com