Vacuum distillation and forming device and method for extracting metal calcium from carbide slag

A distillation device and a technology for extracting metals, applied in metal processing equipment, improvement of process efficiency, ingot casting workshop, etc., can solve the problem that the production site and tail gas emissions do not meet environmental protection requirements, there are no environmental protection facilities and monitoring methods, and the level of process automation Low-level problems, to ensure smooth and stable operation, convenient and fast material delivery, and achieve the effect of distillation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

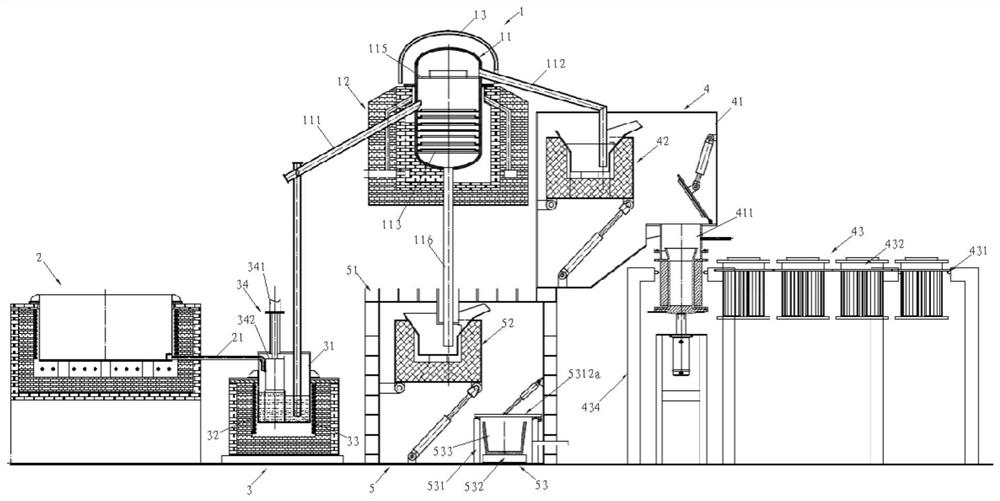

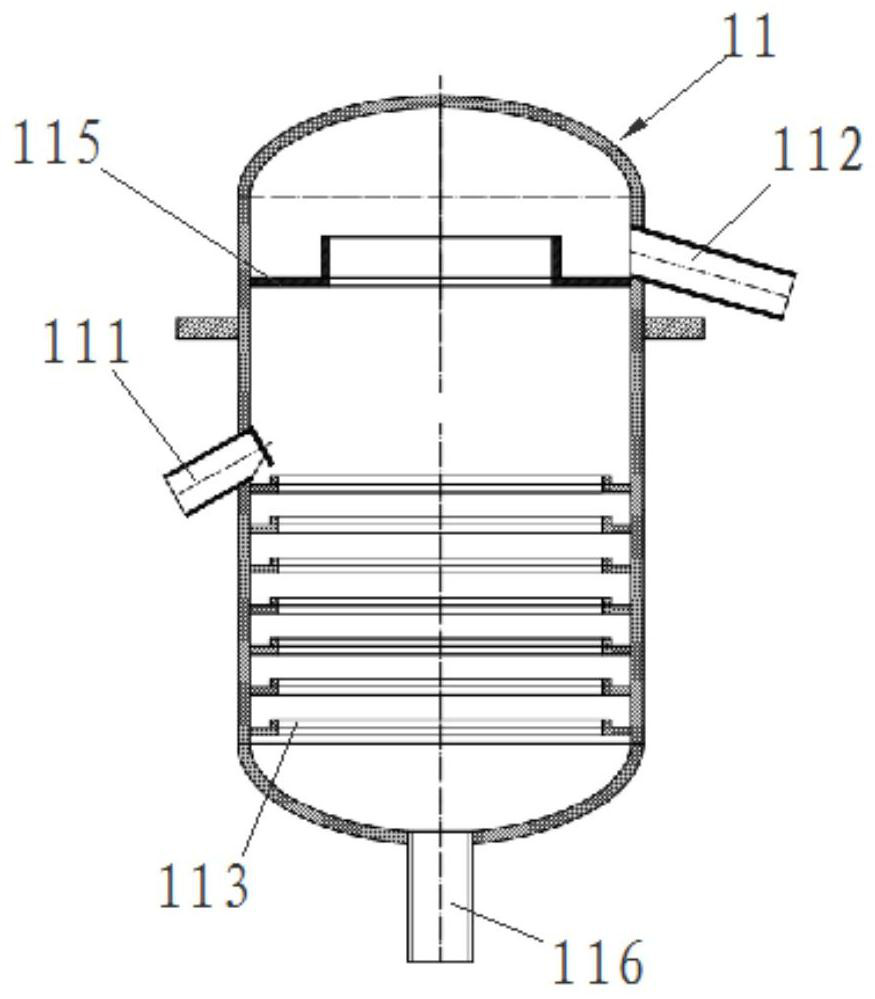

[0109] to combine figure 1 and figure 2 As shown, according to an embodiment of the present invention, the vacuum calcium distillation furnace 11 is provided with a feed pipe 111 for continuous feeding and a refined calcium discharge pipe 112 for continuous discharge. In this embodiment, the feed pipe 111 communicates with the part of the vacuum calcium distillation furnace 11 located in the heating base 12 ; the refined calcium discharge pipe 112 communicates with the part of the vacuum calcium distillation furnace 11 covered with the cooling device 13 .

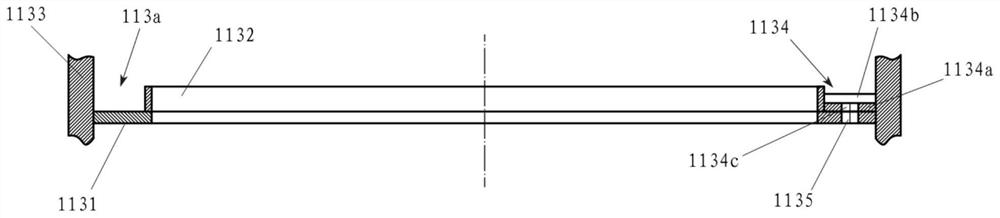

[0110] to combine figure 1 and figure 2 As shown, according to an embodiment of the present invention, a plurality of evaporation trays 113 are arranged in the vacuum calcium distillation furnace 11; in this embodiment, the evaporation trays 113 are annular trays. In this embodiment, the evaporation tray 113 takes heat from the nearby furnace wall of the vacuum calcium distillation furnace 11 to realize the function of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com