Extraction method of agilawood liquid

An extraction method and agarwood liquid technology are applied in the directions of essential oils/spices, fat generation, etc., which can solve the problems that the soaking liquid cannot be completely evaporated to dryness, affect the distillation effect, and the extraction efficiency is low, and reduce energy consumption, improve distillation efficiency, Extraction effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

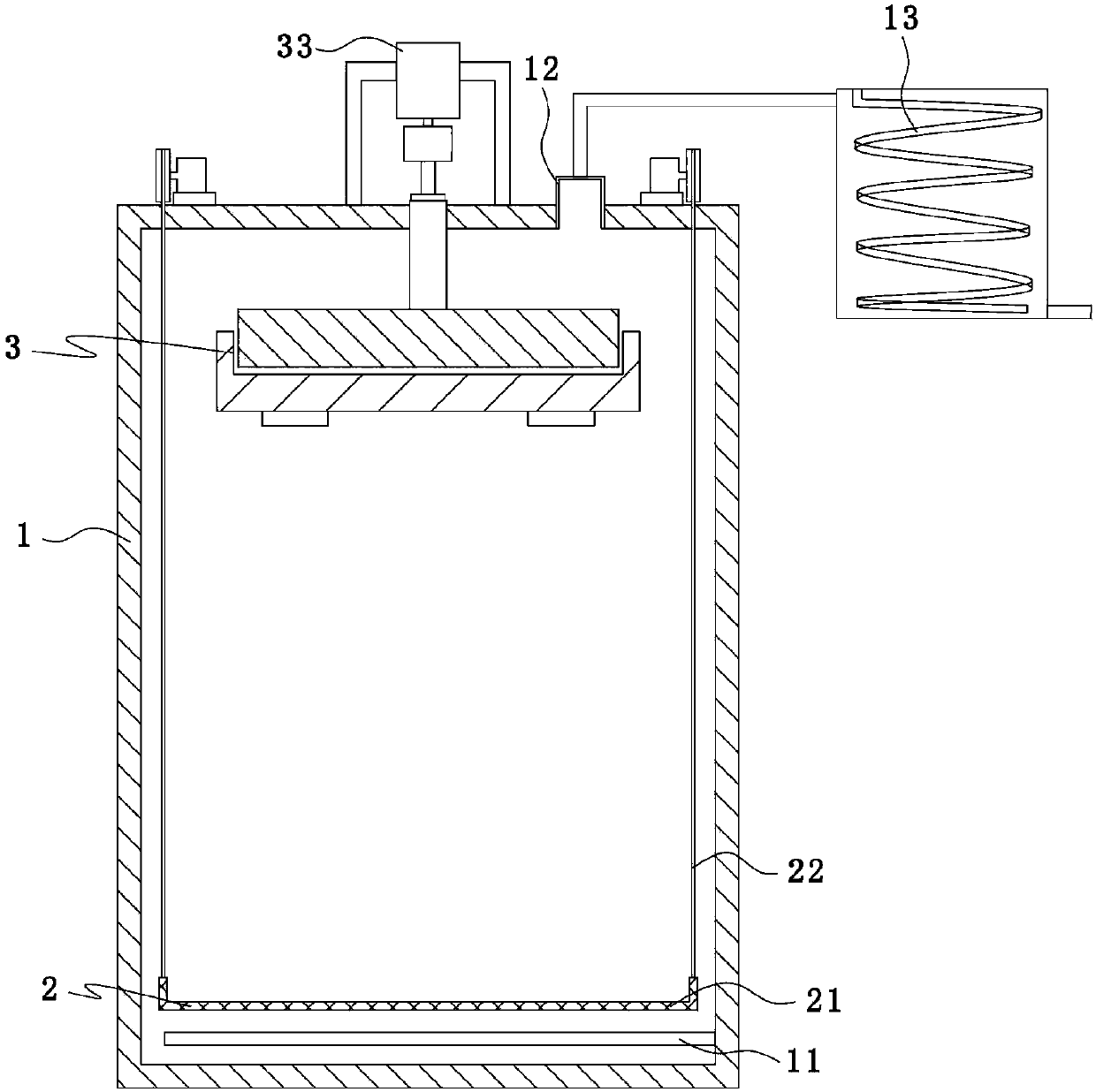

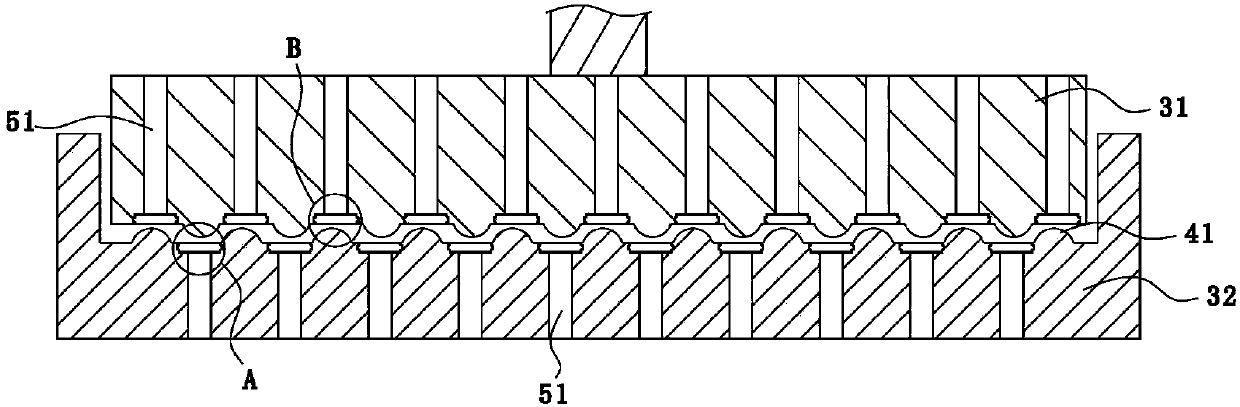

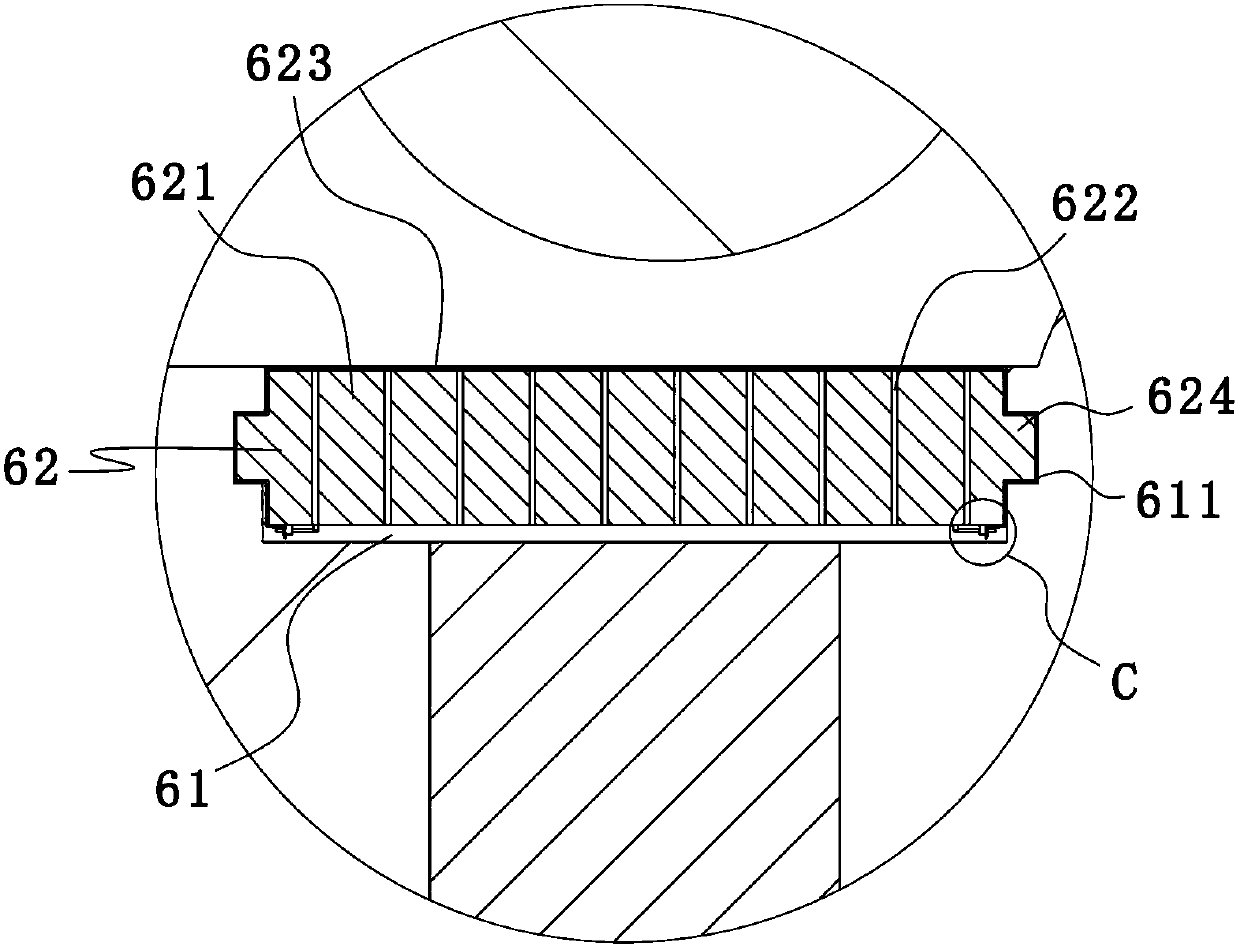

[0030] Such as Figure 1-6 As shown, a method for extracting agarwood liquid includes the following steps: (1) Soaking: Cut agarwood into thumb-sized pieces by a cutting machine, pour clean water into the evaporation chamber, and place the cut pieces of agarwood into the evaporation chamber 1; the massive agarwood is naturally soaked in the water in the evaporation chamber 1 for 5 days to obtain the soaking liquid; in order to prevent the local liquid concentration from being too high and affecting the soaking effect, during the soaking process, the water should be soaked every 8 hours. Stir the soaking liquid once with a stirrer; (2) Filtration: After the soaking is complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com