Method and device for preparing high-purity yellow phosphorus industrially and continuously

A yellow phosphorus, high-purity technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low purification efficiency, unable to meet the requirements of preparing electronic grade phosphoric acid, unable to be used in industrial applications, etc. Distillation efficiency, significant impurity removal effect, and easy safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The rectification tower is first purged with nitrogen to create an inert environment, and then the rectification system is evacuated to a vacuum with a vacuum pump, and the vacuum degree is 10kpa. Sulfuric acid solution and liquid yellow phosphorus heated to 70-80°C are mixed in a molar ratio of 1:100 by a liquid mixer and then added to the distillation tower. The top condenser condenses and returns to the tower. The yellow phosphorus liquid flowing back from the top of the tower and the yellow phosphorus vapor rising from the bottom of the tower are fully contacted in the tower for gas-liquid exchange, and the reflux ratio is adjusted to 1:7. When the product at the top of the tower is qualified, the qualified high-purity yellow phosphorus is recovered. . After completing a process in this way, the content of arsenic in the product high-purity yellow phosphorus is less than 30ppb, the content of antimony is less than 100ppb, and the recovery rate of yellow phosphorus ...

Embodiment 2

[0021] The rectification tower is first purged with nitrogen to create an inert environment, and then the rectification system is evacuated to a vacuum with a vacuum pump, and the vacuum degree is 10kpa. Sulfuric acid solution and liquid yellow phosphorus heated to 70-80°C are mixed in a molar ratio of 1:200 by a liquid mixer and then added to the distillation tower. The top condenser condenses and returns to the tower. The yellow phosphorus liquid flowing back from the top of the tower and the yellow phosphorus vapor rising from the bottom of the tower are fully contacted in the tower for gas-liquid exchange, and the reflux ratio is adjusted to 1:5. When the product at the top of the tower is qualified, the qualified high-purity yellow phosphorus is extracted . By completing a process in this way, the arsenic content in the high-purity yellow phosphorus product is less than 30ppb, the antimony content is less than 100ppb, and the recovery rate of the yellow phosphorus can re...

Embodiment 3

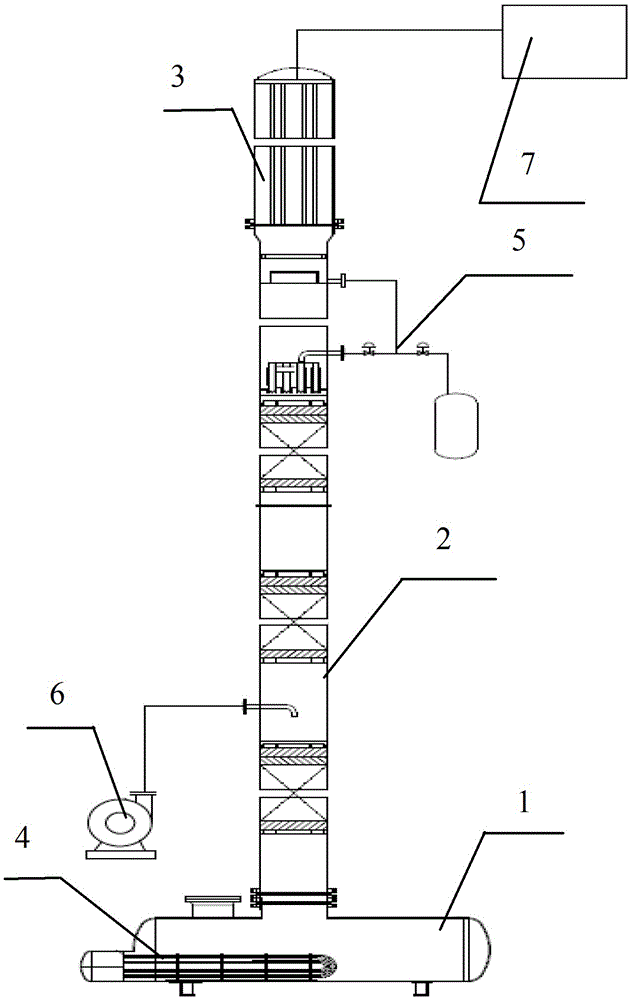

[0023] An industrial continuous production device for high-purity yellow phosphorus, the device includes a tower kettle, a rectification tower is arranged on the tower kettle, an integrated tower top cooler is arranged on the top of the rectification tower, and an integrated tower top cooler is provided with a Vacuum skid-mounted device; the upper part of the rectification tower and the lower part of the integrated tower top cooler are equipped with a gravity reflux extraction device through a conduit, a self-controlled heater is installed in the tower kettle, and a feed pump is installed at the lower part of the rectification tower. When in use, the liquid yellow phosphorus is sent into the device through the feed pump, and evenly sprayed into the rectification tower through the self-operated feed nozzle, and fully contacts with the rising yellow phosphorus vapor in the tower kettle heated by the self-controlled heater in the tower. The high-purity yellow phosphorus condensed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com