Garlic essential oil extraction method

A technology of garlic essential oil and extraction method, which is applied in the directions of essential oil/spice, fat production, etc., can solve the problems of waste of raw materials, difficult separation, and high production cost, and achieve the effects of improving economic value, improving distillation efficiency, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

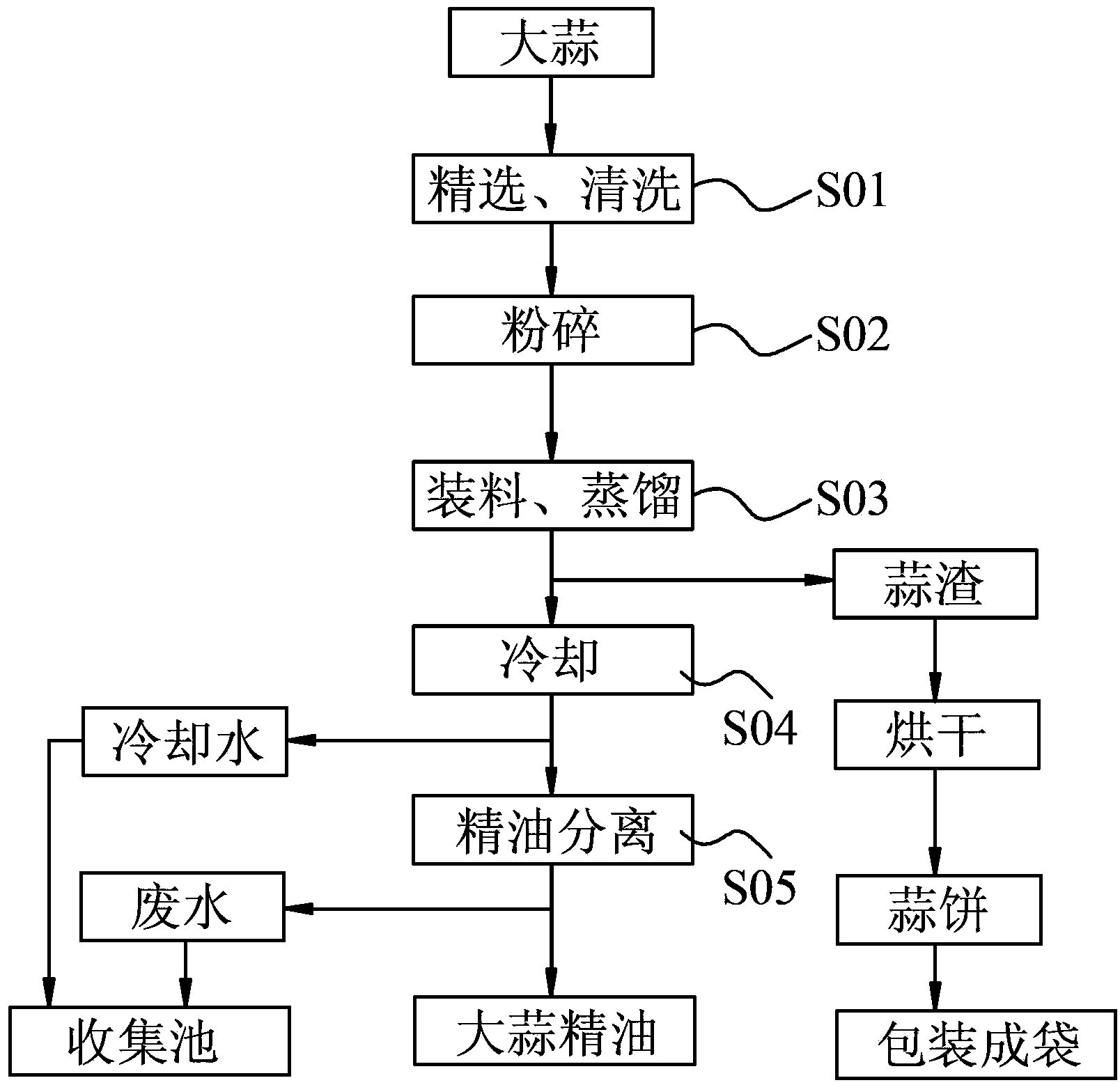

[0031] Such as Figure 1-4 Shown, a kind of garlic essential oil extraction method comprises the following steps:

[0032] Step 1 S01: Select and clean, select pest-free and mildew-free garlic, soak it in water, take out the garlic and rinse it with a high-pressure water gun to remove impurities and soil on the surface of the garlic;

[0033] Step 2 S02: crushing, crushing the cleaned garlic into uniform powder, the particle size of which is 0.2-0.5mm;

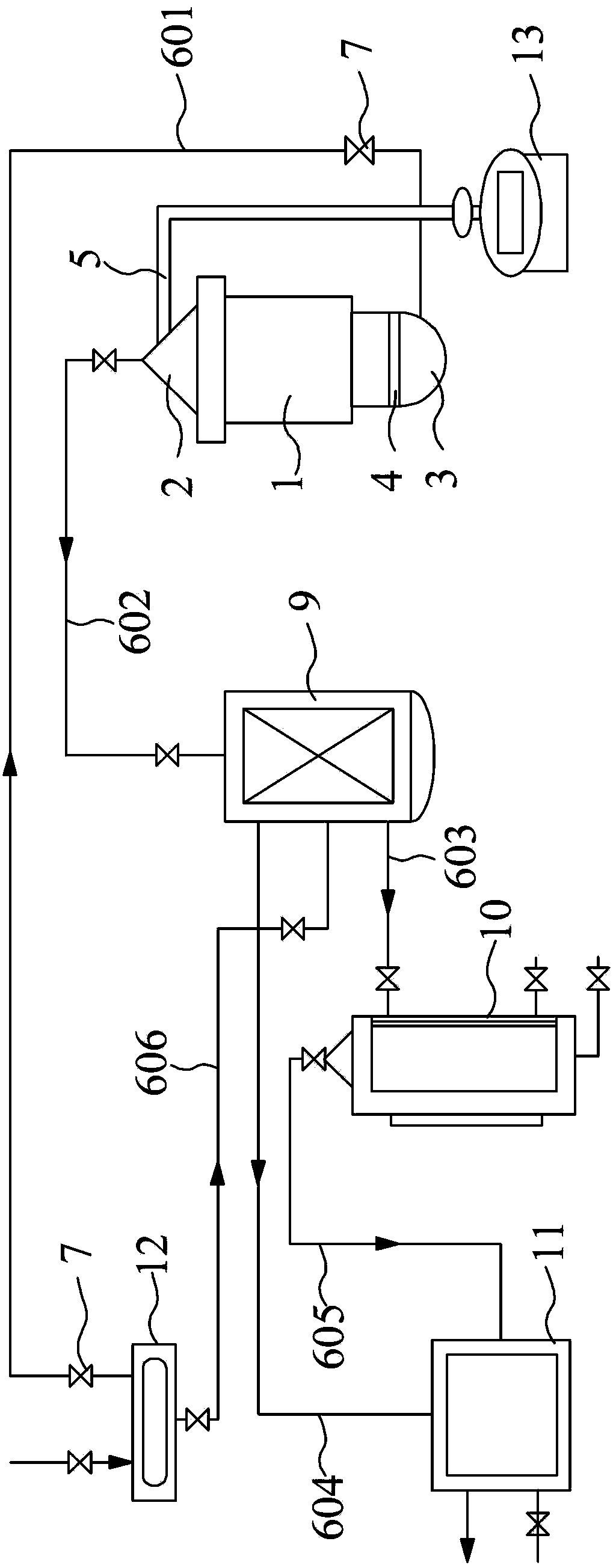

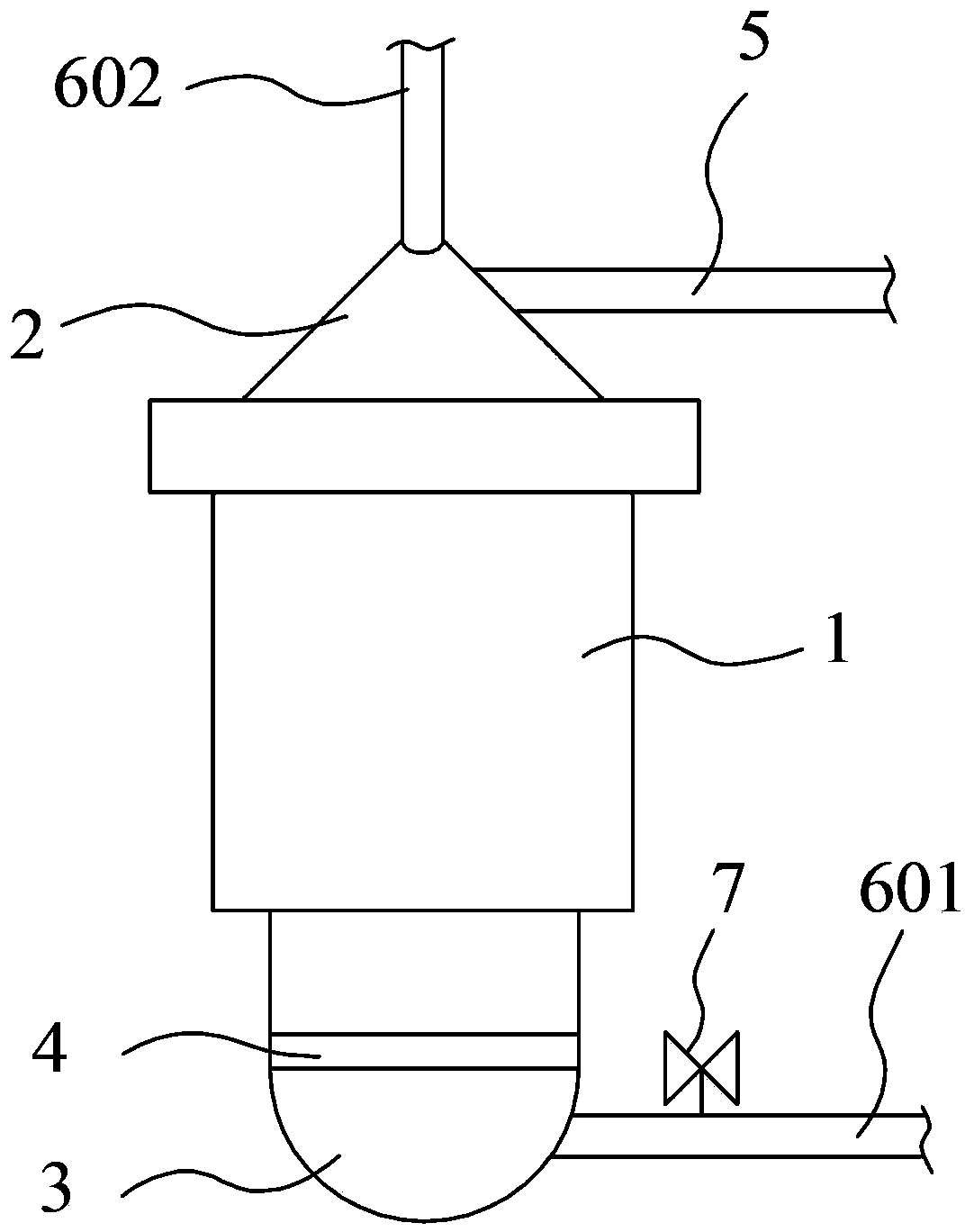

[0034] Step 3 S03: charging and distilling, open the feeding door 2 on the distillation tower 1, and send the minced garlic into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com