Method for preparing furfural from xylose through dehydration via gas-liquid two-phase flow

A technology of flowing xylose and furfural, applied in the field of synchronous separation from the reaction system, can solve the problems of furfural yield, economic efficiency, environmental restrictions, etc., achieve high economic efficiency and environmental benefits, continuous input, and suppress the effect of side reaction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

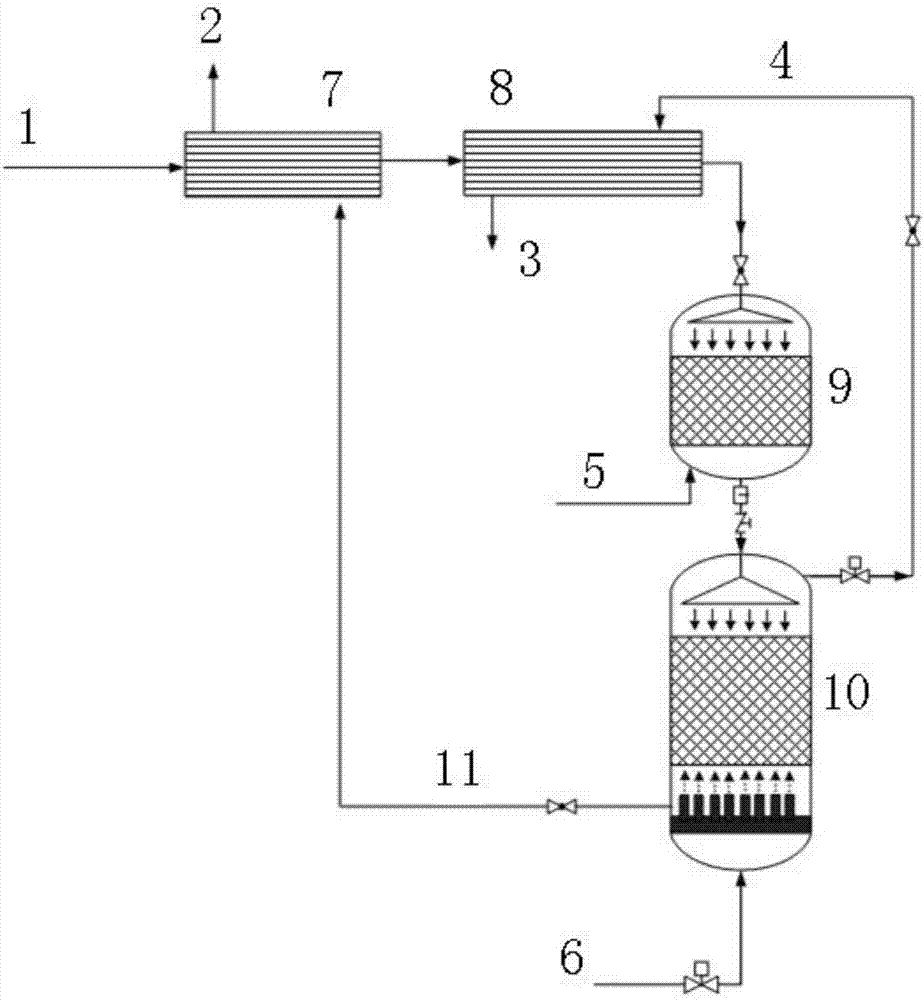

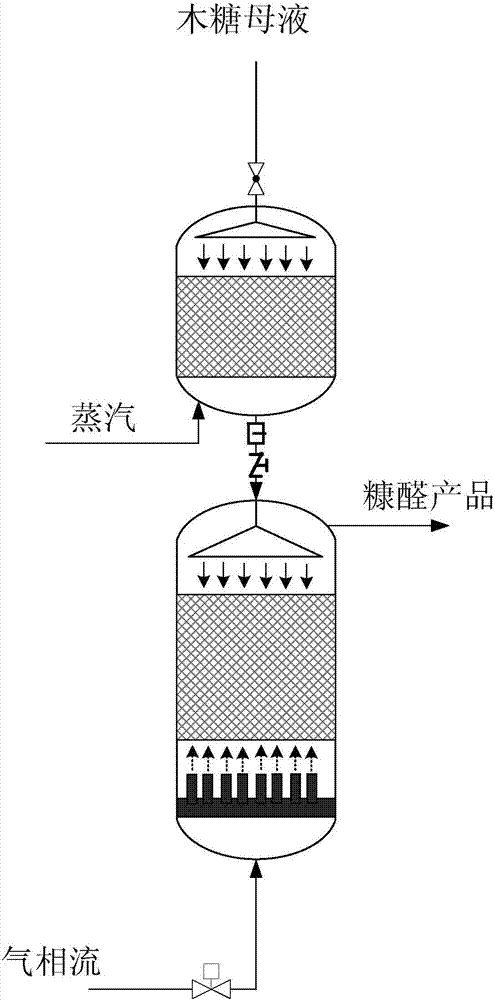

[0045] (1) The HZSM-5 molecular sieve is loaded on the inner wall of the honeycomb ceramics, and placed in the I zone 9 of the packed bed reactor and the II zone 10 of the packed bed reactor. Configuration concentration is the xylose mother liquor of 10wt%, and adds H 2 SO 4 , such that its H 2 SO 4 The concentration is 5wt%, and at the same time, a certain amount of NaCl is added to make the concentration 10wt%.

[0046] (2) The xylose mother liquor 1 prepared in step (1) is continuously pumped into the first heat exchanger 7 by a plunger pump, and is exchanged with saturated steam, and the xylose mother liquor 1 is heated to 80° C. Then the mother liquor continues to enter the second heat exchanger 8, and the xylose mother liquor 1 is heated to 180°C.

[0047] (3) The xylose mother liquor from the second heat exchanger 8 enters the packed bed reactor I zone 9, and is directly mixed with the saturated steam 5 at 230° C., the xylose mother liquor is heated to 200° C., and ...

Embodiment 2

[0052] (1) The mordenite molecular sieve is loaded on the inner wall of the honeycomb ceramics, and placed in the I zone 9 of the packed bed reactor and the II zone 10 of the packed bed reactor. Configuration concentration is the xylose mother liquor of 15wt%, and adds acetic acid, makes its acetic acid concentration be 5wt%, adds a certain amount of ZnCl simultaneously 2 , so that its concentration is 10wt%.

[0053] (2) The xylose mother liquor 1 prepared in step (1) is continuously pumped into the first heat exchanger 7 by a plunger pump, and is exchanged with saturated steam, and the xylose mother liquor 1 is heated to 80° C. Then the mother liquor continues to enter the second heat exchanger 8, and the xylose mother liquor is heated to 180°C.

[0054] (3) The xylose mother liquor from the second heat exchanger 8 enters the packed bed reactor I zone 9, and is directly mixed with the saturated steam 5 at 230° C., the xylose mother liquor is heated to 220° C., and part of t...

Embodiment 3

[0058] (1) Mordenite molecular sieve and ZnCl 2 After being mixed at a mass ratio of 1:1, it is loaded on the inner wall of the honeycomb ceramics and placed in zone 9 of the packed bed reactor and zone 10 of the packed bed reactor II. Configuration concentration is the xylose mother liquor of 15wt%, and adds acetic acid, makes its acetic acid concentration be 5wt%, adds a certain amount of CaCl simultaneously 2 , so that its concentration is 10wt%.

[0059] (2) The xylose mother liquor prepared in step (1) is continuously pumped into the first heat exchanger 7 by a plunger pump to exchange heat with saturated steam, and the xylose mother liquor 1 is heated to 80° C. Then the mother liquor continues to enter the second heat exchanger 8, and the xylose mother liquor 1 is heated to 180°C.

[0060] (3) The xylose mother liquor from the second heat exchanger 8 enters the packed bed reactor I zone 9, and is directly mixed with 230°C saturated steam, the xylose mother liquor is he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com