Concrete continuous stirring and conveying system device

A conveying system and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, mixing operation control device, etc. It can solve the problems of large installation space, low productivity, and occupation of weighing scales, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

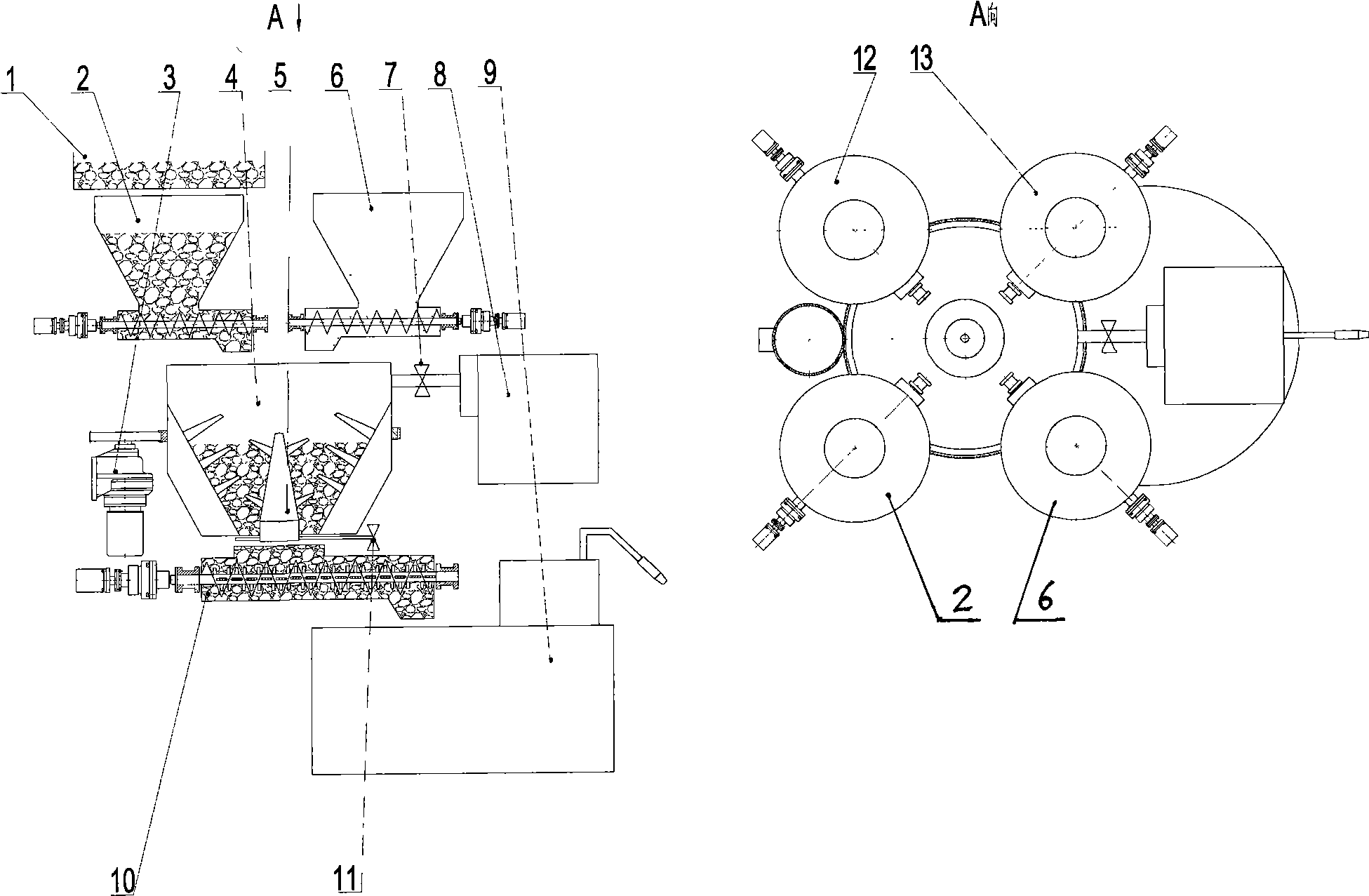

[0012] The following will be combined with figure 1 Embodiments of the present invention will be described in detail.

[0013] A continuous concrete mixing and conveying system device, which consists of a gravel sieve 1, a gravel metering and conveying system 2, a concrete mixing drum drive motor 3, a concrete mixing drum 4, a fixed concrete mixer 5, a sand metering and conveying system 6, and a water inlet regulating valve 7. Water tank and pumping system 8. Concrete storage tank and pumping system 9. Concrete secondary mixing and conveying system 10. Concrete conveying regulating valve 11. Cement metering and conveying system 12. Additive metering and conveying system 13. The whole system works At this time, by controlling the motor speed of the metering and conveying system of each component, the feeding amount of each component during the mixing of the whole system can always maintain the required concrete ratio. in:

[0014] The gravel metering conveying system 2, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com