Strontium-barium salt continuous leaching and deslagging production system and production process

A technology of production system and production process, applied in the direction of calcium carbonate/strontium/barium, magnesium/calcium/strontium/barium sulfide/polysulfide, strontium carbonate, etc. Corrosion, impact and other issues of the frame, to reduce safety and environmental hazards and improve safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

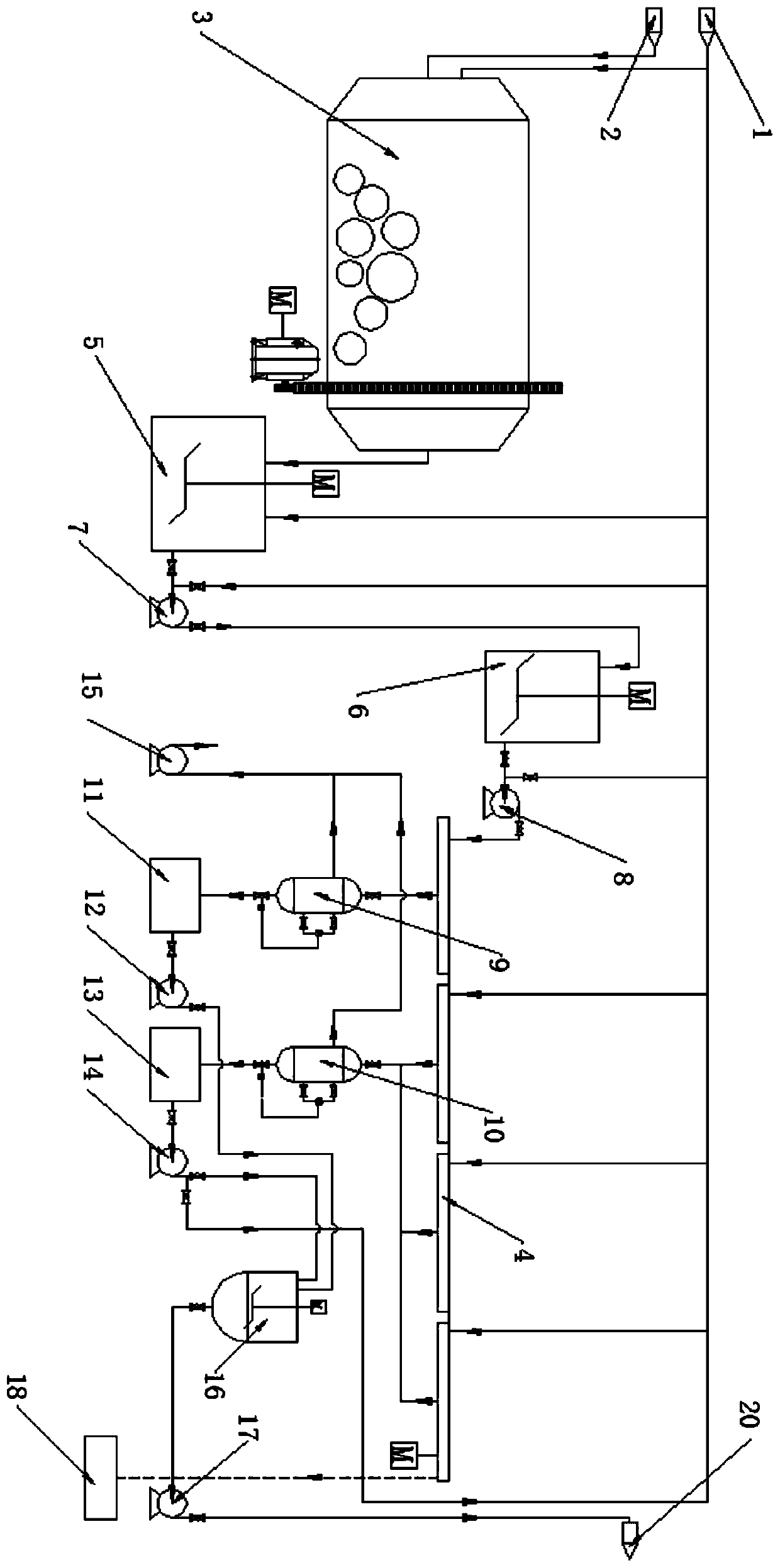

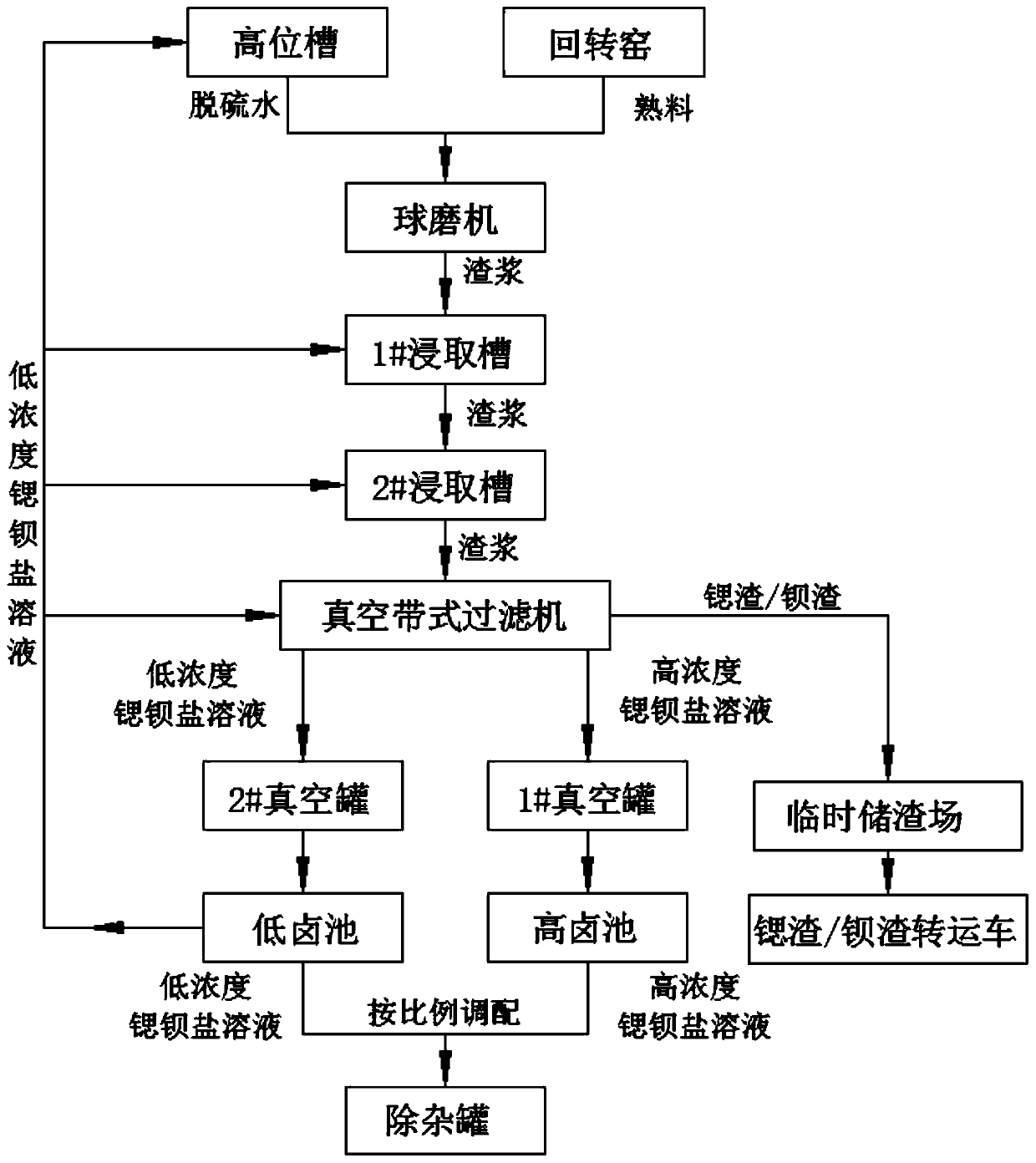

[0030] a kind of like figure 1 The shown strontium barium salt continuous leaching and slag production system is characterized in that it includes a ball mill 3 connected to the discharge port of the rotary kiln 2, and the discharge port of the ball mill 3 is sequentially connected to 1# leaching tanks 5 and 2# The leaching tank 6, the 2# leaching tank 6 is connected to the belt vacuum filter 4, the belt vacuum filter 4 is provided with a multi-stage washing device, the front end of the belt vacuum filter 4 The filtrate delivery pipe is connected to the 1# vacuum tank 9 and the high-halogen pool 11 in turn, and the filtrate delivery tube at the rear end of the belt vacuum filter 4 is connected to the 2# vacuum tank 10 and the low-halogen pool 13 in turn; the high-halogen pool 11 , low-halogen pool 13 are respectively connected to the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com