Vertical continuous induction type high-temperature graphitization furnace

A high-temperature graphitization and vertical technology, applied in the field of graphitization equipment, can solve the problems of short production life, high failure rate, and large consumption of thermal insulation materials, so as to improve battery quality, continuously and stably discharge materials, increase production and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

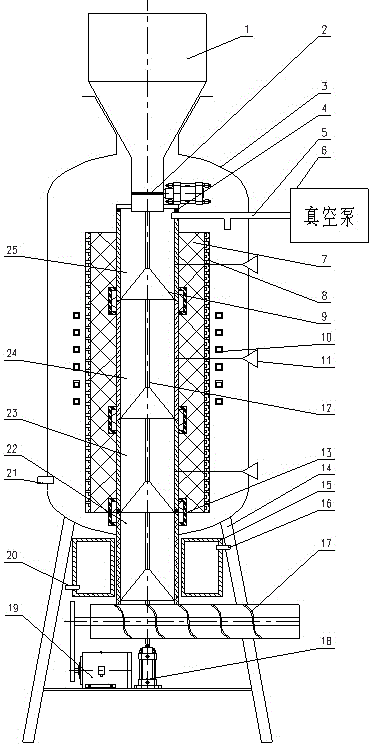

[0025] A vertical continuous induction high-temperature graphitization furnace, such as figure 1 As shown, it includes a hopper 1, a furnace body part, a furnace bottom part, and a discharge part, and has a vertical structure. material part. The top part of the furnace body structure is connected to the hopper 1 with an electric valve 2 controlled by PLC program, the lower outlet of the electric valve 2 is connected to the preheating zone 25, and the joint between the electric valve 2 and the preheating zone 25 is provided with a gasket 4 The lining is placed vertically, and there is an exhaust pipe 5 at the top, which can discharge the cleaning gas and exhaust gas inside the furnace tube. Four conical partition bells 9 are installed on the central axis 12 of the work area, and the preheating zone 25 is connected with the heating District 24, heating district 24 and cooling district 23 and the connection of cooling district 23 and water-cooling district 22 are all fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com