Pecan shelling machine

A hickory and feeding hopper technology, which is applied in the field of forestry dried hickory nut shelling and kernel extraction machinery, can solve the problems of low kernel integrity, low work efficiency, and slow speed, so as to reduce the probability of pollution and improve production efficiency , the effect of a high ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

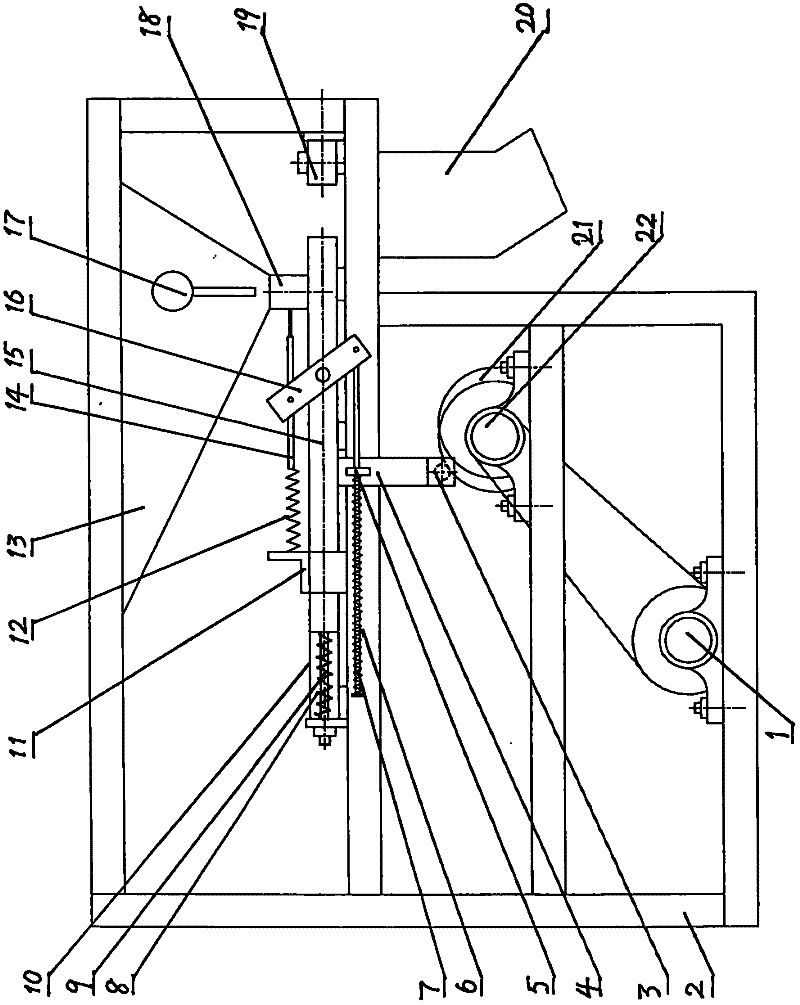

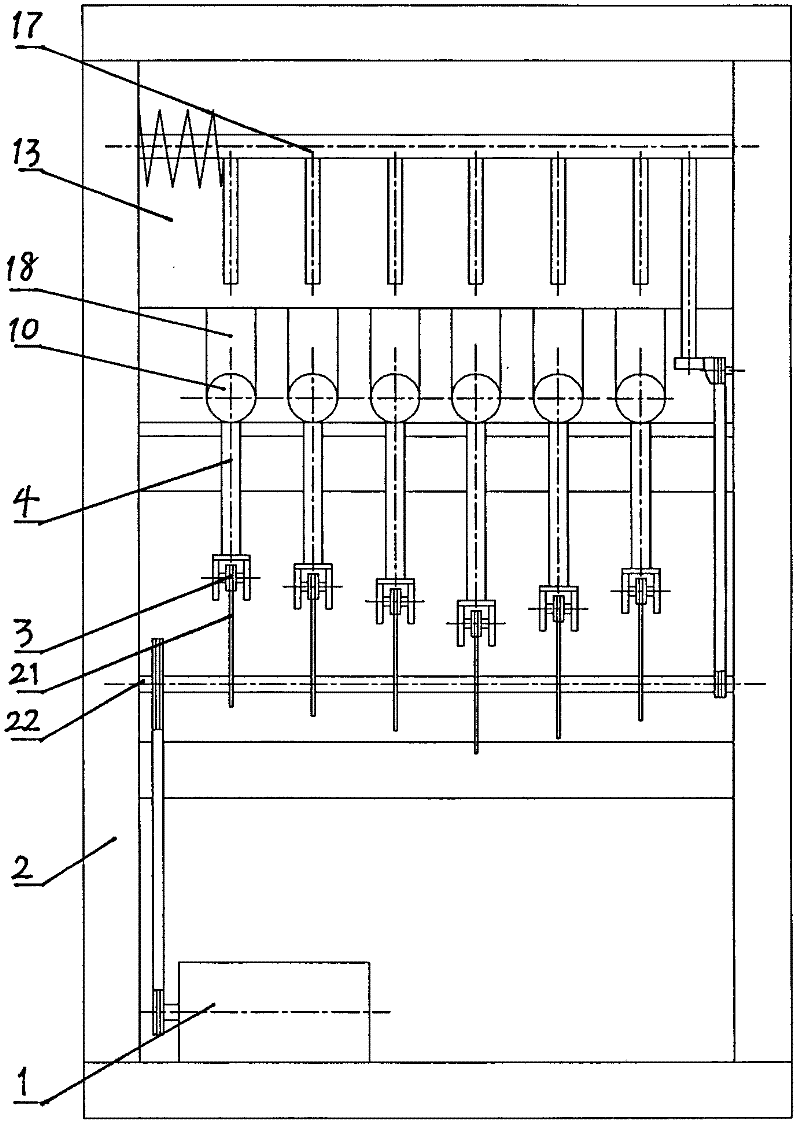

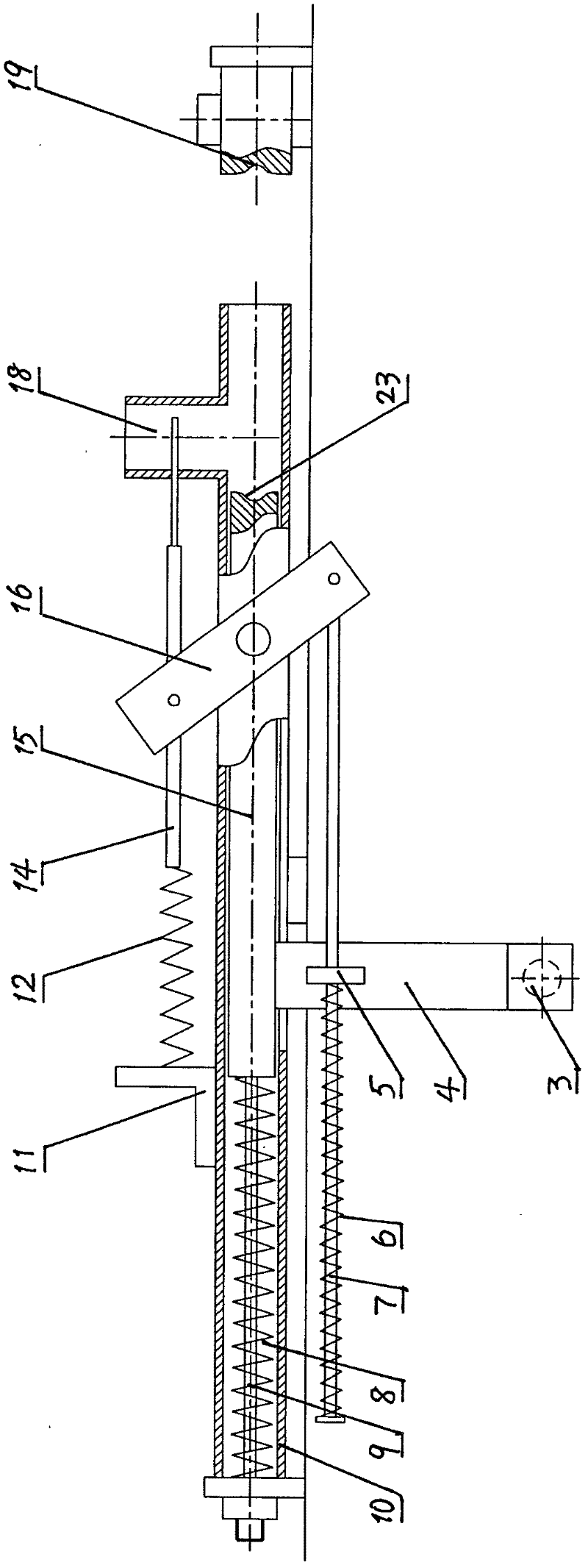

[0014] The present invention will be described in detail with reference to the embodiments and with reference to the accompanying drawings: the core innovation of the present invention has two points: one is to use two concave socket surfaces as the pinching surface of the hickory nut, and the force is even and dispersed, and there is no concentration of brittle kernels The second is to use elastic impact parts to generate cushioning force during impact, reduce the inertial impact force, and make the kernels not easy to break, so that the kernels can be beneficially obtained. refer to figure 1 and figure 2 , the hickory nut shelling and whole kernel machine, including frame 2, feed hopper 13, discharge hopper 20, motor 1 and its transmission device, from top to bottom is feed hopper 13 successively, and there is a pull grid in the feed hopper 17. There is a fruit drop tube 18 at the bottom of the feed hopper, and the inner diameter of the fruit drop tube is greater than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com