P-cresol preparation method and equipment

A technology of p-cresol and sodium cresate, which is applied in the chemical industry, can solve problems such as difficult production control, harsh reaction conditions, and impact on product quality, and achieve good environmental protection effects, short process, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The following specific examples illustrate the implementation process and beneficial effects of the present invention in detail, which are intended to help readers better understand the essence and characteristics of the present invention, and are not intended to limit the scope of implementation of this case.

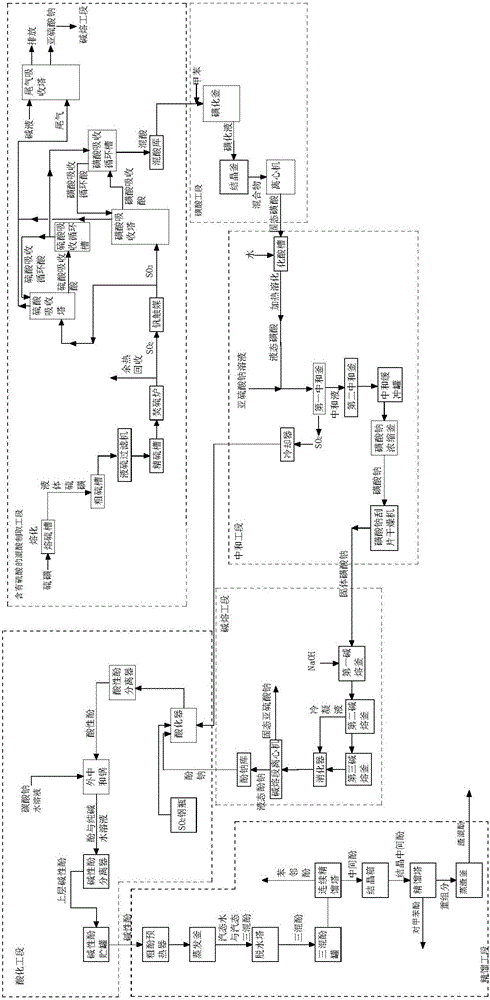

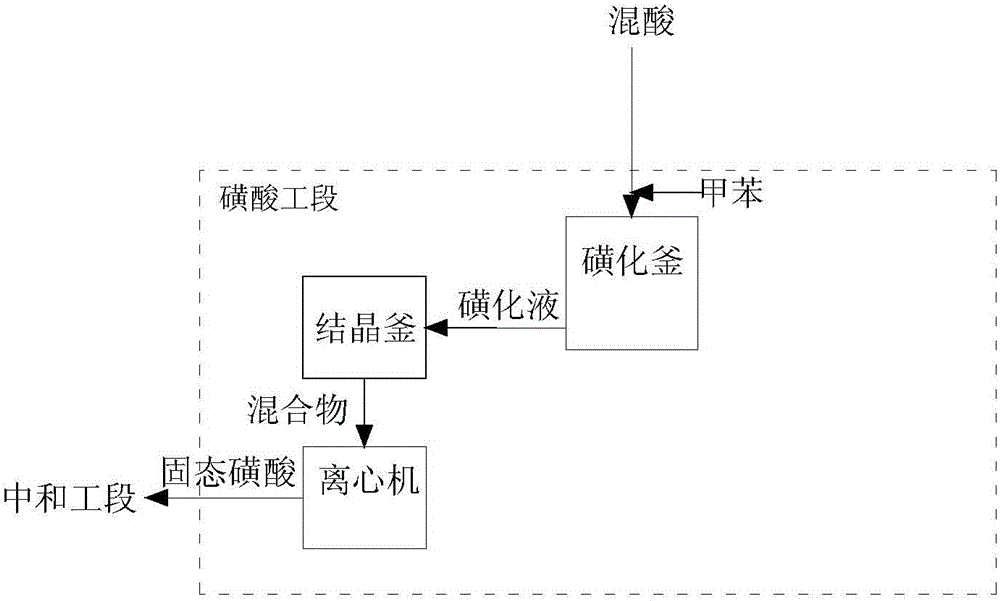

[0077] Combined with the current mature toluene sulfonation alkaline fusion process for the production of p-cresol, the inventor changed most of the intermittent production mode to continuous production mode, reducing the number of equipment and investment under the condition of a certain capacity. Increase production capacity. The continuous production process of the present invention is divided into six sections, such as figure 1 Shown:

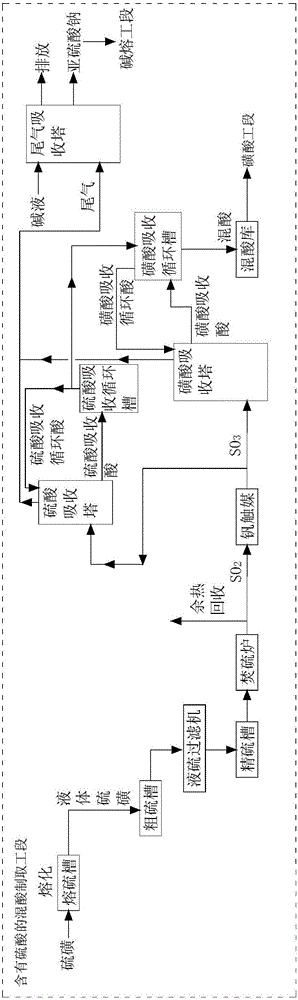

[0078] (1) Sulfur trioxide production section (such as figure 2 Shown):

[0079] 1. Sulfur incineration process: solid sulfur is transported by belts to melt in the sulfur melting tank, and liquid sulfur flows from the overflow to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com