Reaction sintering lightweight silicon carbide mirror blank and preparation method thereof

A sintered silicon carbide, light weight technology, applied in the field of optical materials, can solve the problems of unseen lightweight silicon carbide mirror blank products, etc., and achieve the effect of easy implementation, simple process method, and fine grains

Active Publication Date: 2012-03-14

SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Up to now, there are no relevant patents and literature reports on the preparation of lightweight silicon carbide mirror blank products using reaction sintered silicon carbide materials prepared by porous carburizing silicon carbide

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

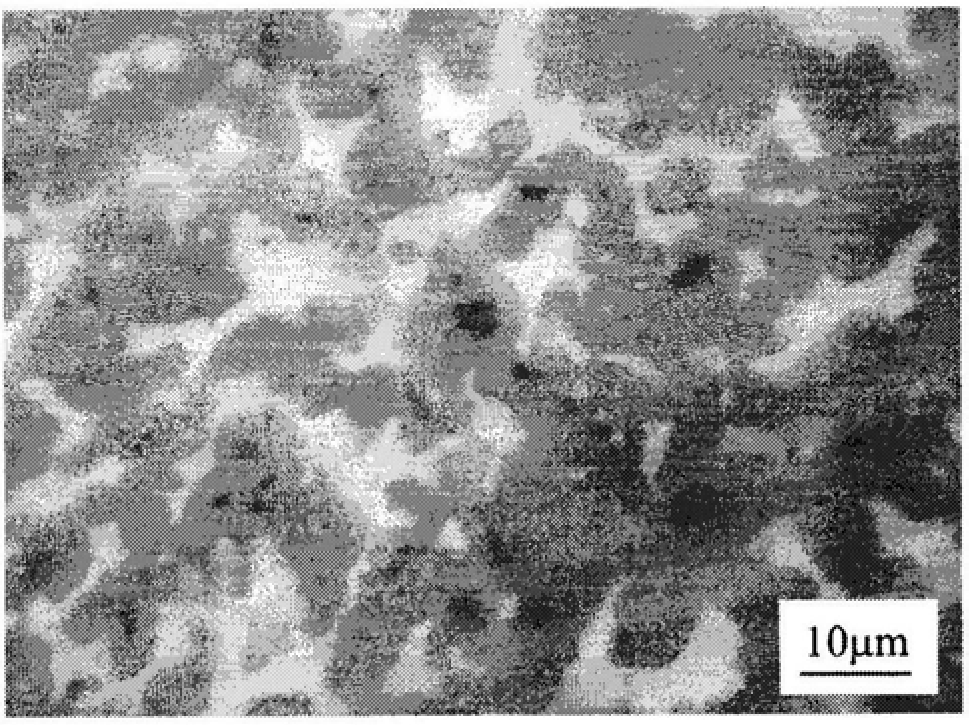

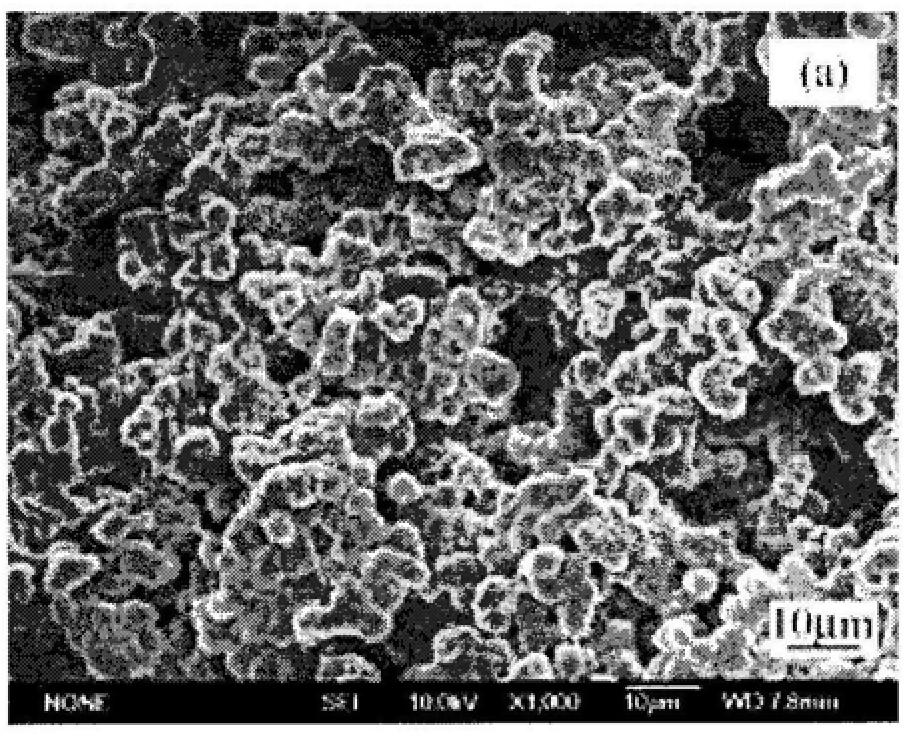

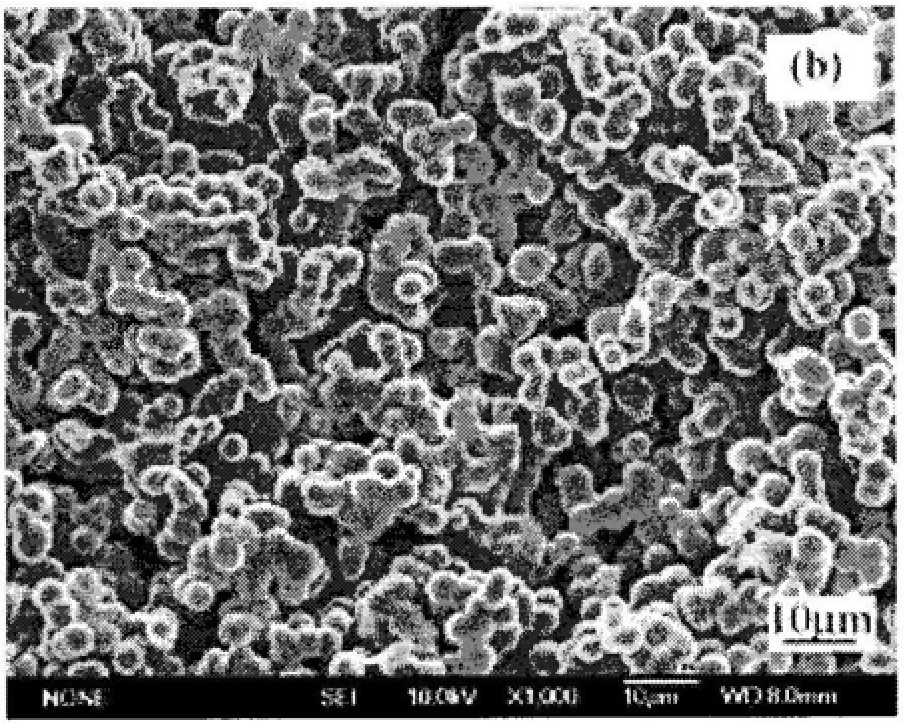

The invention relates to a reaction sintered lightweight silicon carbide reflective mirror blank and a preparation method thereof, belonging to the field of optical materials. The invention adopts the method of porous carburizing silicon carbide to prepare reaction sintered silicon carbide material, and further prepares light-weight silicon carbide mirror blank. The present invention is characterized in that furfuryl alcohol and / or furfuryl alcohol resin is used as carbon source, alcohols such as diethylene glycol are used as solvent and pore-forming agent, p-toluenesulfonic acid or sodium p-toluenesulfonate is used as catalyst, and polymerization phase separation technology is adopted The green body of pure porous carbon with controllable pore size was prepared, and the reaction sintered silicon carbide was prepared by liquid phase or vapor siliconizing. The silicon carbide mirror blank provided by the present invention does not contain the original added coarse silicon carbide particles in the blank, and all the silicon carbide in the product is formed in the reaction process, so the prepared silicon carbide material is different from the traditional reaction sintered silicon carbide Compared with the material, the material has the advantages of uniform microstructure, fine crystal grains, low silicon content, excellent performance, etc.; at the same time, the preparation method of the mirror blank provided by the invention is simple in process and easy to implement, and the prepared mirror blank has high reliability and stable quality.

Description

Reaction sintering lightweight silicon carbide mirror blank and preparation method thereof technical field The invention relates to a reaction sintered lightweight silicon carbide reflective mirror blank and a preparation method thereof, belonging to the field of optical materials. Background technique Lightweight space mirrors are the core components of space remote sensing optical systems. Initially, fused silica and glass-ceramics were mainly used as mirror materials. With the gradual improvement of the resolution of the space remote sensing optical system, the diameter of the reflector also increases, the overall quality of the optical system continues to increase, and the requirements for the temperature control system are also getting higher and higher. In this case, materials such as Be and SiC with excellent properties such as low density, low thermal expansion coefficient, high specific stiffness, and high thermal conductivity have become the main candidates for l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G02B5/08C01B31/36C04B35/65

Inventor 黄政仁陈忠明刘学建姚秀敏闫永杰袁明杨金晶江东亮

Owner SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com