Coking wastewater membrane concentration salt separation zero-emission treatment system and coking wastewater membrane concentration salt separation zero-emission treatment method

A technology for coking wastewater and a treatment method, which is applied in the field of water treatment and can solve the problems of high disposal costs and the inability of coking enterprise wastewater discharge to meet new and special discharge requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the examples, and those skilled in the art should understand that the examples are only for illustration and do not constitute any limitation to the present invention.

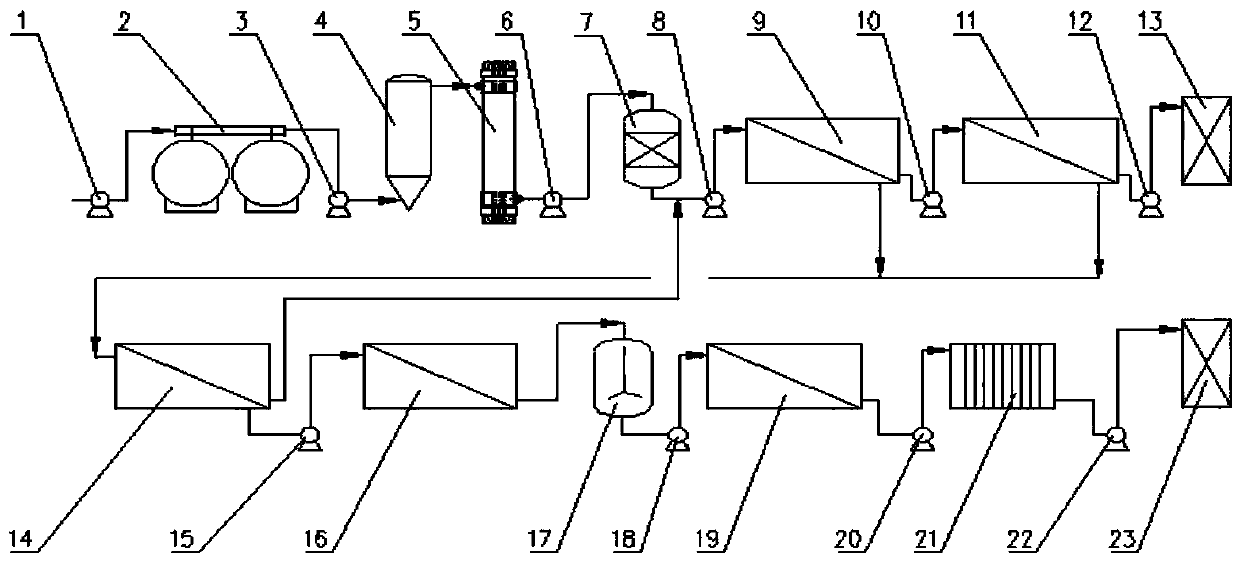

[0037] As shown in the figure, the amount of coking wastewater after biochemical treatment is 120m 3 / h, the amount of coking wastewater after activated carbon adsorption, softening, ultrafiltration, and reverse osmosis membrane concentration treatment is 25m 3 / h, the water quality index is: PH is 7.5, COD is 550mg / l, Cl - 9000mg / l, SO 4 2- 12000mg / l, Na + 13000mg / l, F - The total cyanide is 150mg / l, the total cyanide is 15mg / l, the total nitrogen is 300mg / l, the calcium is 30mg / l, the magnesium is 10mg / l, the TDS (total dissolved solids) is 30000mg / l, and the suspended solids (SS) is 50mg / l l. Pump the above waste water into the automatic sand filter to remove the suspended solids (SS) to less than 5mg / l. The automatic san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com