Method for jointly producing sulphuric acid and cement clinker by using sulphur gas to reduce gypsum

A technology for making cement clinker and gypsum, which is used in cement production, clinker production, chemical instruments and methods, etc., can solve the problem of increasing the total gas volume of gypsum calcination and gypsum reduction, difficult to completely discharge liquid sulfur, and increasing calcination energy consumption, etc. It can reduce the energy consumption of the reduction reaction, ensure long-term stable operation, and facilitate the control of calcination and decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

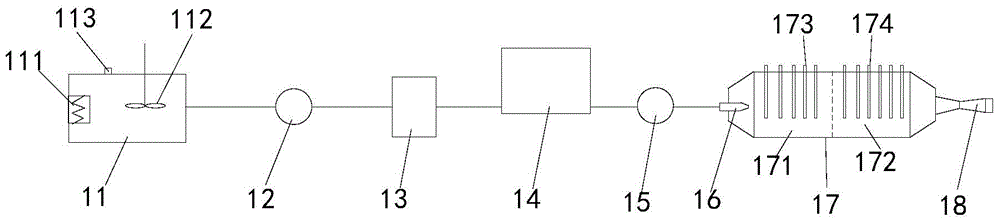

[0075] The process of the high temperature sulfur gas preparation device is as follows:

[0076] Add solid or liquid sulfur to the sulfur melting tank 11, under the heating action of the steam heater 111, when the temperature is heated to more than 103°C, the solid melts and becomes liquid, and as the temperature further increases to above 140°C, the flow of liquid sulfur The performance reaches the best state, and the crude sulfur delivery pump 12 is sent to the sulfur filter 13 for filtration to remove solid impurities in the sulfur, and the refined liquid sulfur is sent to the refined sulfur tank 14 for buffer storage, and steam heating keeps the temperature of the refined sulfur tank at 140 ~150°C, and then sent to the atomizing nozzle 16 installed at the feed end of the gasifier through the refined sulfur delivery pump 15.

[0077] The gasifier 17 is heated by a carbon fiber quartz electric heating tube, and the internal temperature is controlled at 450-800°C. Under this...

Embodiment 1

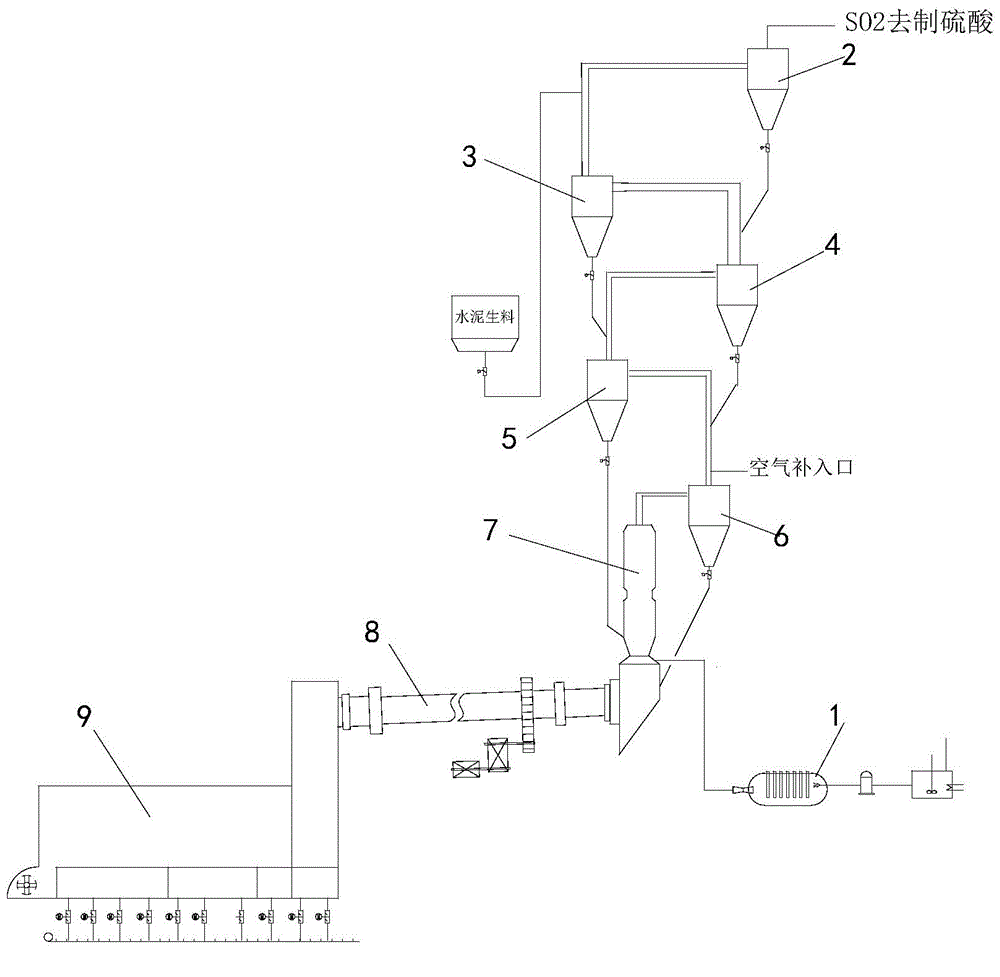

[0079] Such as figure 1 As shown, add desulfurized gypsum (containing 8-15% of free water) into a rotary dryer to exchange heat with hot flue gas for drying and dehydration treatment, remove free water and part of crystal water in it, and produce hemihydrate gypsum. Add pyrite slag, fly ash, and bauxite to the dehydrated gypsum, and make cement raw meal according to the three-rate value, and send it to the silo through the elevator. The raw meal is sent to the first to fourth-stage cyclone separators after metering. , 3, 4, 5 imports, and from calcining rotary kiln 8 and reduction furnace 7 containing SO 2 The gas is subjected to gas-solid countercurrent contact heat exchange, and the solid raw material undergoes 4 heat exchanges from top to bottom, and the temperature of the material rises to 600-800 ° C, and then enters the reduction furnace 7 . The superheated sulfur gas from the high-temperature sulfur gas preparation device 1 has a temperature of 550-800°C and is sent to...

Embodiment 2

[0086] Phosphogypsum dihydrate, a by-product of wet-process phosphoric acid production, is used as the main calcium sulfate raw material. The phosphogypsum material usually contains 25-30% free water. The drying and dehydration time of phosphogypsum is long, and the rotary dryer needs a little longer. Phosphogypsum after removing free water is mixed with other materials to make cement raw meal.

[0087] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com