Full-PE fireproof net and preparation method thereof

A technology of fireproof net and round yarn, which is applied in the manufacture of fireproof and flame-retardant filaments, stretch spinning, textiles, etc. It can solve the problems of high cost, easy deformation, poor high temperature resistance of PVC, etc., and achieves convenient operation and high shrinkage rate. Low, strong impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

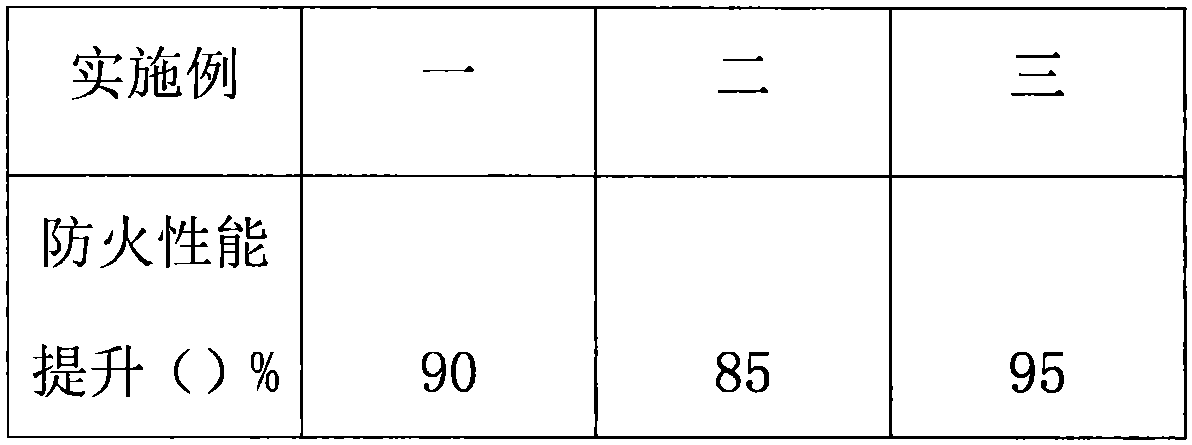

Embodiment 1

[0020] A kind of all-PE fireproof net proposed in this embodiment includes flat wire and round wire, and the round wire includes the following components, 75 parts of polyethylene particles, and 25 parts of flame retardant;

[0021] The flat yarn comprises the following components: 75 parts of polyethylene particles, 22 parts of flame retardant, and 3 parts of color masterbatch.

[0022] A kind of preparation method of all PE fireproof net, it comprises the following steps,

[0023] S1, drawn round wire, select polyethylene particles with suitable composition ratio and flame retardant to the hopper of the mixer, mix evenly and pull out the round wire;

[0024] S2, draw flat yarn, select polyethylene particles, flame retardant, and color masterbatch with suitable composition ratio, add them to the hopper of the mixer, mix them evenly, and draw out the flat yarn;

[0025] S3, weaving a net, the round yarn obtained in the S1 step is used as a warp, the flat yarn obtained in the ...

Embodiment 2

[0031] A kind of all-PE fireproof net proposed in this embodiment includes flat wire and round wire, and the round wire includes the following components, 85 parts of polyethylene particles, and 15 parts of flame retardant;

[0032] The flat yarn comprises the following components: 83 parts of polyethylene particles, 15 parts of flame retardant, and 3 parts of color masterbatch.

[0033] A kind of preparation method of all PE fireproof net, it comprises the following steps,

[0034] S1, drawn round wire, select polyethylene particles with suitable composition ratio and flame retardant to the hopper of the mixer, mix evenly and pull out the round wire;

[0035] S2, draw flat yarn, select polyethylene particles, flame retardant, and color masterbatch with suitable composition ratio, add them to the hopper of the mixer, mix them evenly, and draw out the flat yarn;

[0036] S3, weaving a net, the round yarn obtained in the S1 step is used as a warp, the flat yarn obtained in the ...

Embodiment 3

[0042] A kind of all-PE fireproof net proposed in this embodiment includes flat wire and round wire, and the round wire includes the following components, 80 parts of polyethylene particles, and 20 parts of flame retardant;

[0043] The flat yarn comprises the following components: 83 parts of polyethylene particles, 14 parts of flame retardant, and 3 parts of color masterbatch.

[0044] A kind of preparation method of all PE fireproof net, it comprises the following steps,

[0045] S1, drawn round wire, select polyethylene particles with suitable composition ratio and flame retardant to the hopper of the mixer, mix evenly and pull out the round wire;

[0046] S2, draw flat yarn, select polyethylene particles, flame retardant, and color masterbatch with suitable composition ratio, add them to the hopper of the mixer, mix them evenly, and draw out the flat yarn;

[0047] S3, weaving a net, the round yarn obtained in the S1 step is used as a warp, the flat yarn obtained in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com