Preparation method of soybean protein acid sodium

A technology of sodium soybean proteinate and soybean protein, which is applied in the field of preparation of sodium soybean proteinate, can solve the problems of not meeting production requirements and limitations, and achieve the effect of expanding the application range and application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

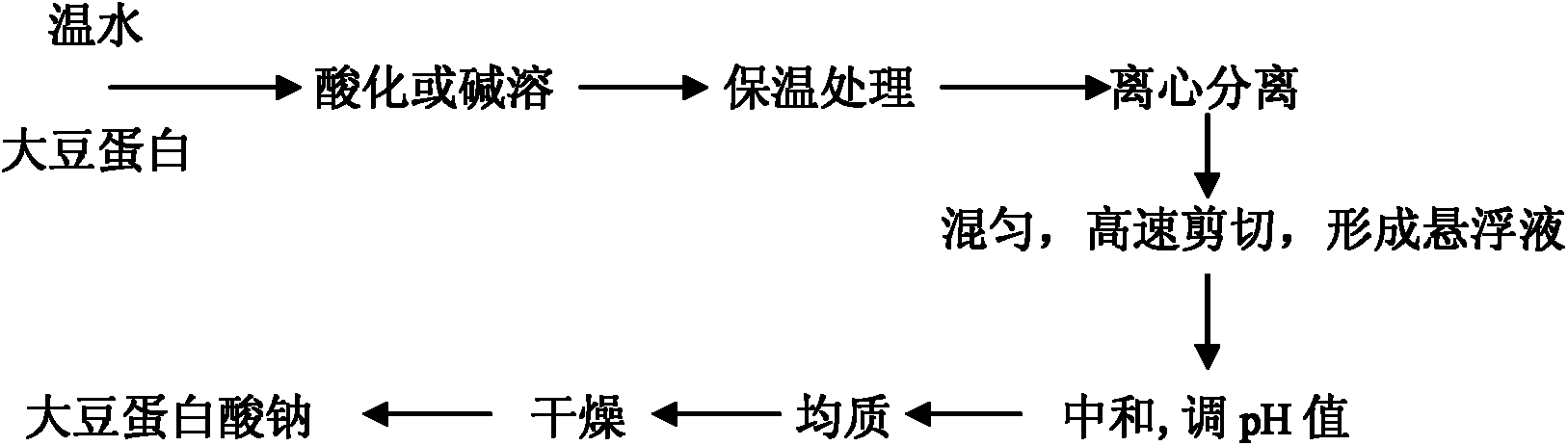

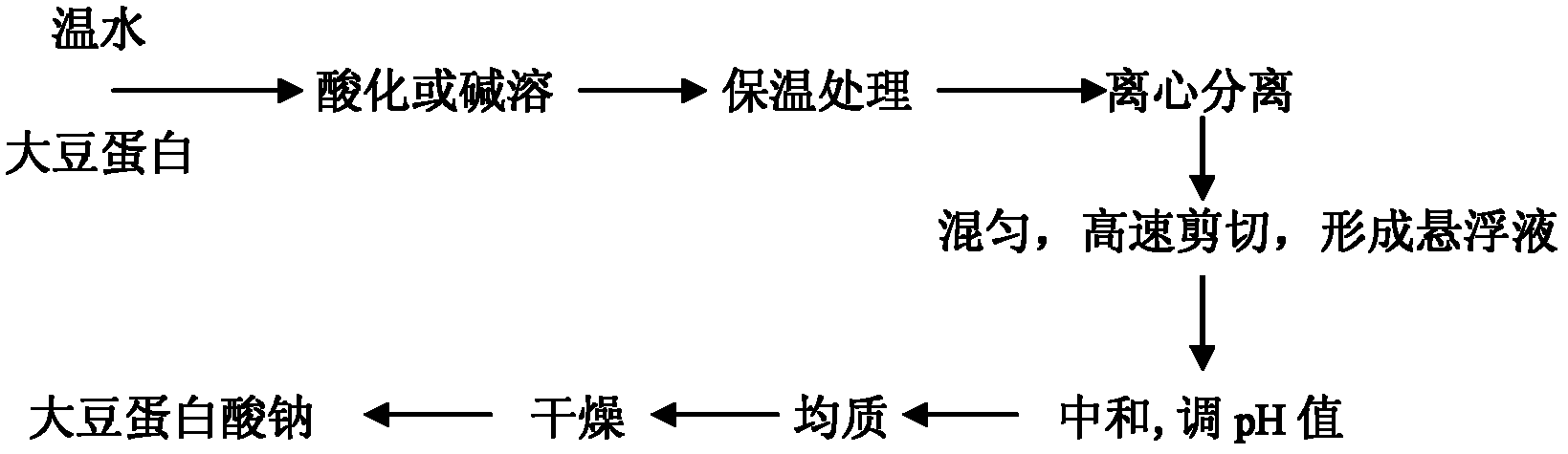

Image

Examples

Embodiment 1

[0025] Example 1: Take soybean protein and mix it with warm water at 20°C-40°C. The amount of warm water added is calculated by adding 1g soybean protein to 10-20ml warm water. Use sodium hydroxide solution to adjust pH=7.5, extract for 30-60min, 4000r / min Centrifuge to remove the residue, take the supernatant and acidify it with hydrochloric acid or citric acid, that is, use 0.1-1.0mol / L hydrochloric acid or citric acid to adjust the pH value of the supernatant to 4.5-4.8 to obtain a mixture, and the temperature of the mixture is controlled at 70-80°C Incubate for 60-120min, cool to room temperature and centrifuge to remove the supernatant. Take the protein-rich substance and add water to the precipitate, the amount of water added is 2.5-3.5 times the weight of the precipitate, then put it into a vortex mixer to mix evenly, and then put it into a high-speed shear emulsifier under the condition of 5000-6000r / min for high-speed shearing to form suspension. Then add 0.1-1.0mol / ...

Embodiment 2

[0026] Example 2: Take soybean protein and mix it with warm water at 20°C-40°C. The amount of warm water added is calculated by adding 1g soybean protein to 10-20ml warm water. Use ammonium hydroxide solution to adjust pH=8.0, extract for 40-80min, 3500r / min Centrifuge to remove the residue, take the supernatant and acidify it with hydrochloric acid or citric acid, that is, use 0.1-1.0mol / L hydrochloric acid or citric acid to adjust the pH value of the supernatant to 4.5-4.8 to obtain a mixture, and the temperature of the mixture is controlled at 80-100°C Incubate and precipitate for 30min-120min, cool to room temperature and centrifuge to remove the supernatant. Take the precipitate and add water, the amount of water added is 2.5-3.5 times the weight of the precipitate, then put it into a vortex mixer to mix evenly, and then put it into a high-speed shear emulsifier to perform high-speed shear under the condition of 6000-7000r / min to form a suspension. Add 0.1-1.0mol / L Na 3 ...

Embodiment 3

[0028] Example 3: Take soybean protein and add warm water at 20°C-40°C to mix. The amount of warm water added is calculated as 1g soybean protein is added to 10-20ml warm water, and then carry out alkali dissolution, that is, add 0.1-1.0mol / L Na 2 CO 3 solution, NaHCO 3 solution or hydrogen phosphate buffer solution to adjust the pH value to 8.0-9.0, control the temperature at 90-100°C for 60min-120min, cool to room temperature and centrifuge to remove the precipitate, take the protein-rich substance, that is, the upper layer suspension, put the upper layer suspension Put it into a vortex mixer to mix evenly, and then put it into a high-speed shear emulsifier to perform high-speed shear under the condition of 5500-6500r / min to form a suspension. Add 0.1-1.0mol / L hydrochloric acid or citric acid to neutralize and adjust pH=7.0-7.5, homogenize at 1000-2500psi for at least 20-35 seconds. After homogenization, the protein solution is spray-dried to obtain sodium soybean proteina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com