Preparation method for polyepoxy sodium succinate for water treatment

A technology of sodium polyepoxysuccinate and water treatment, which is applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc. It can solve the problems of large concentration differences, hydrogen peroxide peroxidation, poor stability, etc. problem, achieve conditional equilibrium, avoid peroxidation, and avoid the effect of sodium tartrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

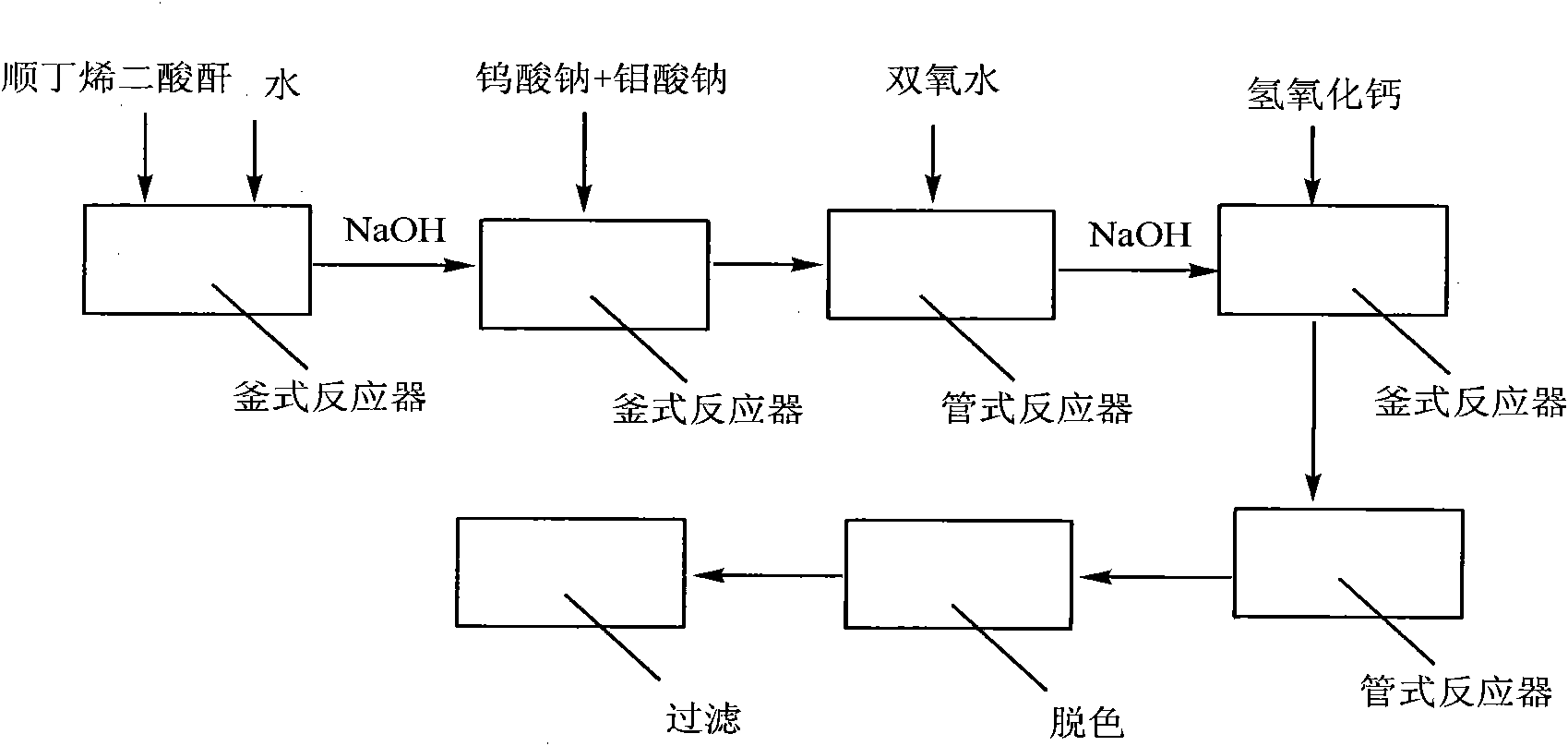

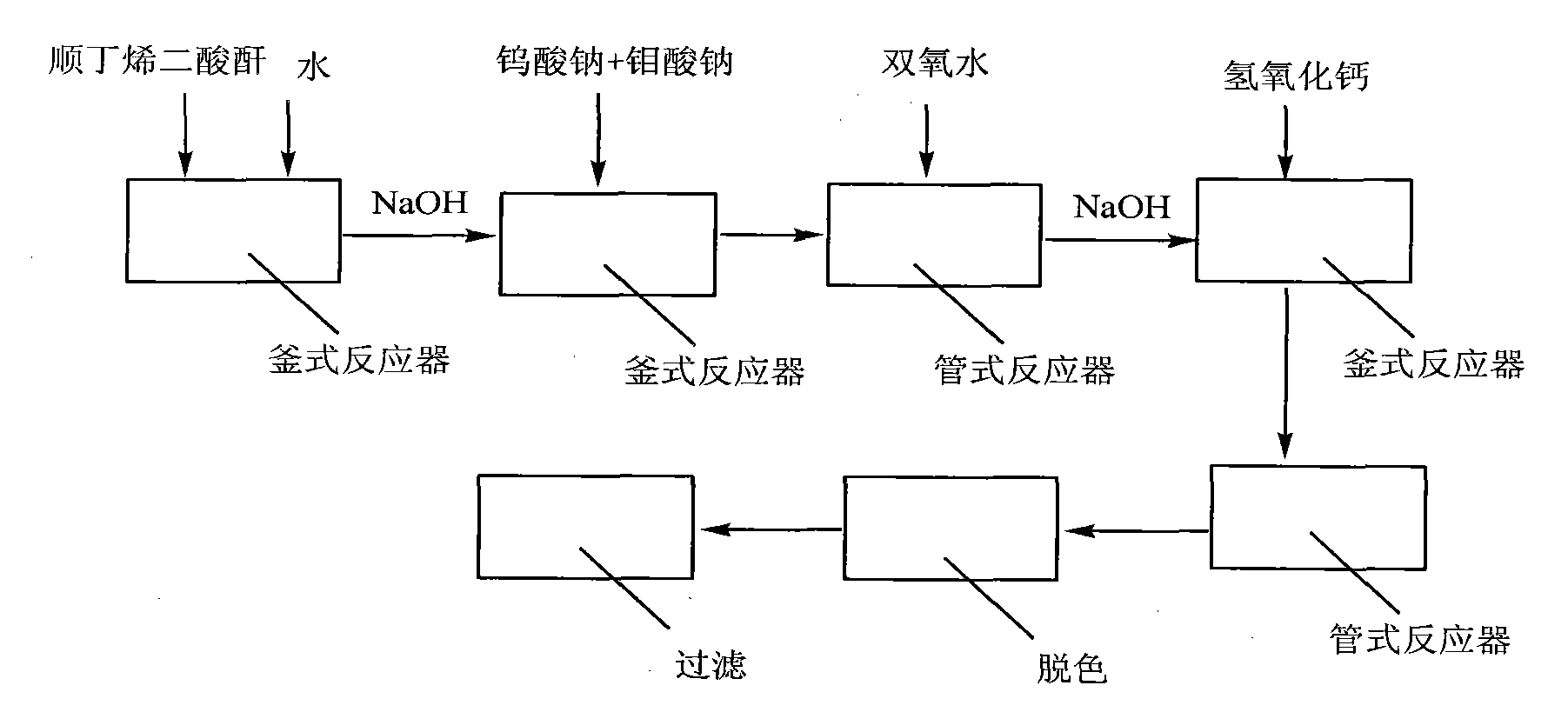

Method used

Image

Examples

Embodiment 1

[0026] Add 220 kg of maleic anhydride and 240 kg of water into the reaction kettle and stir; add 560 kg of 40% sodium hydroxide dropwise, neutralize the temperature below 60°C, and adjust the pH to about 6.5; add 5 kg of sodium molybdate and tungsten A mixture of sodium bicarbonate; heat up to 65°C, make the material in the kettle and 280 kg of hydrogen peroxide with a concentration of 30% enter the tubular reactor in equal proportions to start the circulation of the material in the kettle; the cyclization time is 1.5 hours, and the cyclization is completed and used in the regulating kettle Adjust the pH to about 6.5 with sodium hydroxide; keep it warm for 1 hour; raise the temperature to 95°C, add about 15 kg of calcium hydroxide, add in two times, and adjust the pH to 10.8 with sodium hydroxide at the same time; pump the reaction mixture into the tube In the reactor, the diameter of the tube reactor is Φ80cm, the tube length is 80m, and the tube reactor is kept warm for 40 ho...

Embodiment 2

[0028] Add 245 kg of maleic anhydride and 220 kg of water into the reaction kettle and stir; add 520 kg of 40% sodium hydroxide dropwise, neutralize at 50°C, and adjust the pH to about 6.5; add 10 kg of sodium molybdate catalyst; When the temperature reaches 65°C, turn on the circulation pump, so that the materials in the kettle and 300 kg of hydrogen peroxide with a concentration of 40% enter the tubular reactor in equal proportions to start the circulation of the materials in the kettle; the cyclization time is 1.0 hours, and after the cyclization is completed, use sodium hydroxide to adjust the pH at About 6.5; keep warm for 1 hour; heat up to 90°C, add about 20 kg of calcium hydroxide, add in two times, and adjust pH = 10 with sodium hydroxide at the same time; pump the reaction mixture into the tubular reactor, the tubular reactor The diameter of the reactor is Φ50cm, the length of the tube is 120m, and the tube reactor is kept warm for 60 hours. Add decolorizer, keep war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com