Process and system for recovering sodium sulfate from high-salt and high-COD wastewater in zero-discharge manner

A sodium sulfate, zero-discharge technology, applied in alkali metal sulfite/sulfate purification, multi-stage water treatment, water/sewage treatment and other directions, can solve the problem that sodium sulfate products cannot meet the requirements of Class I first-class products, and the system operation Instability, poor reliability of zero-emission and other problems, to achieve the effect of increasing the output of frozen thenardite, saving energy consumption, and improving anti-scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

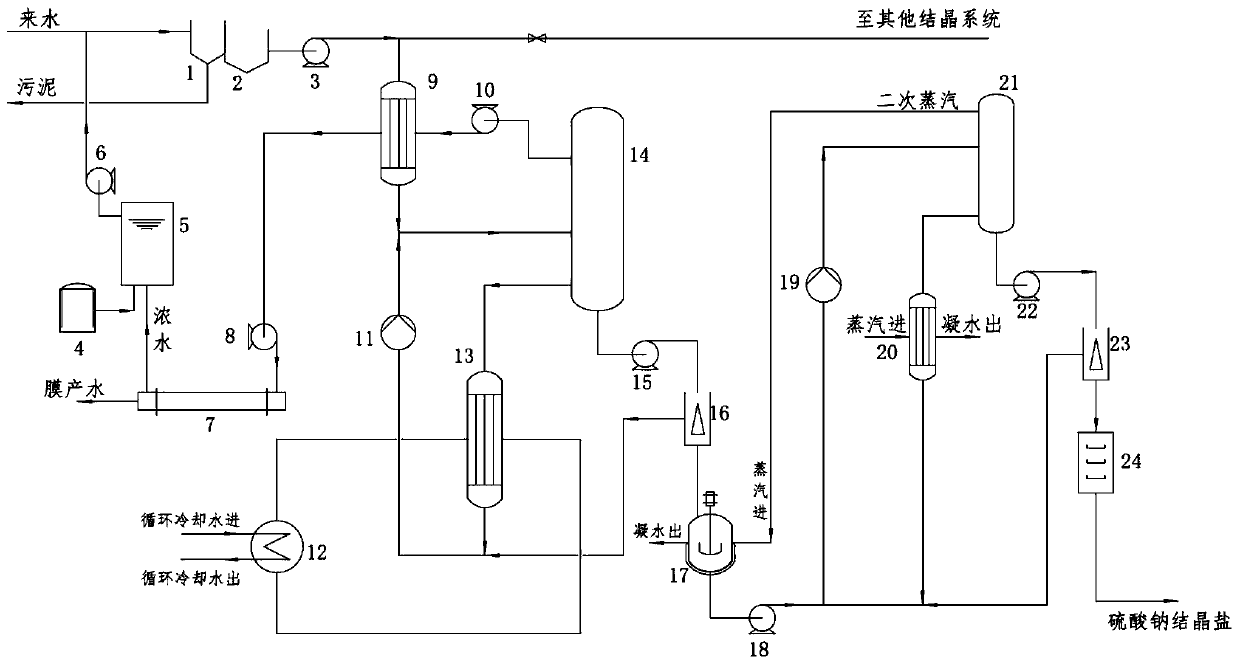

[0068] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

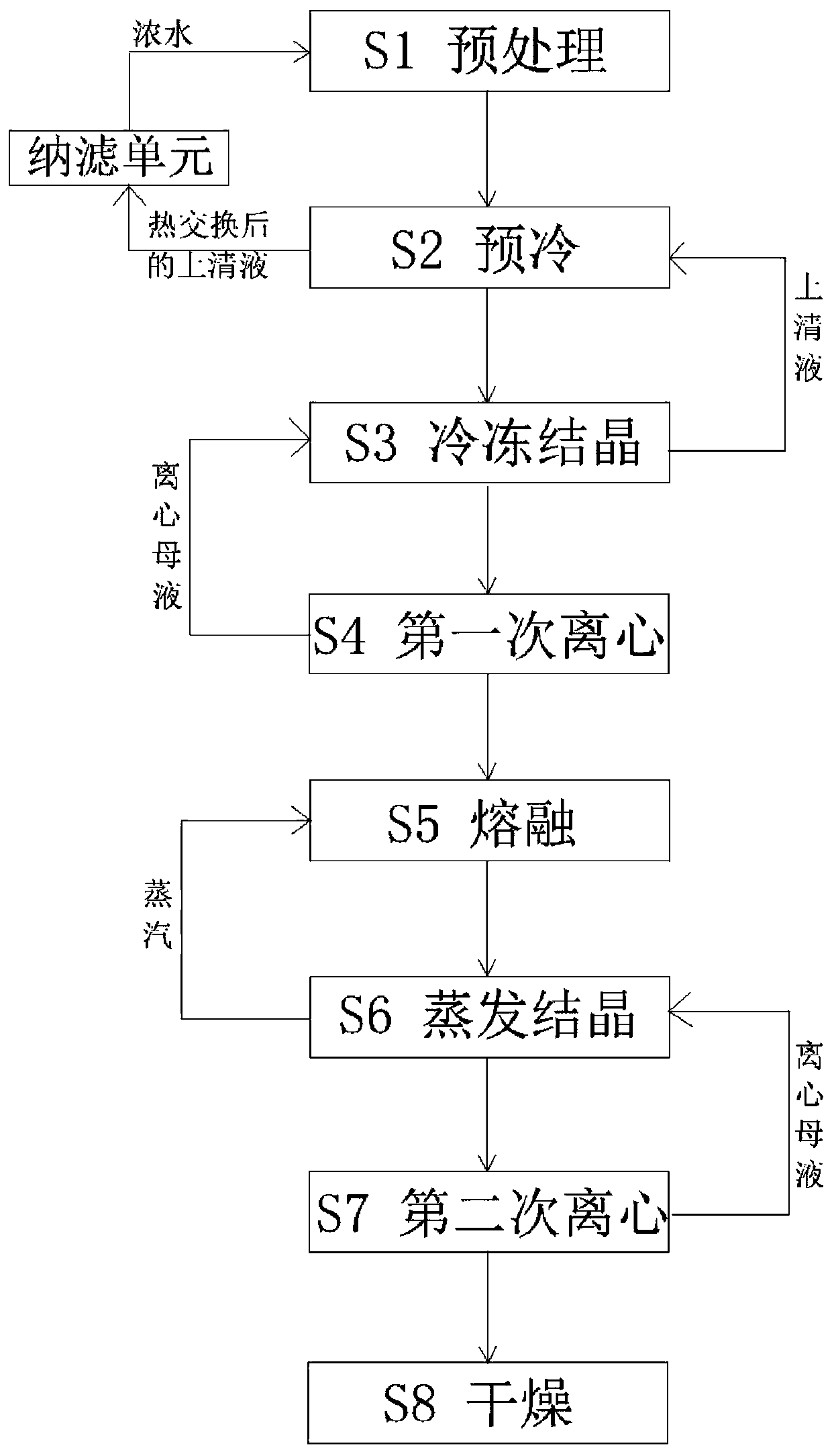

[0069] Such as figure 1 Shown, a kind of high-salt high-COD waste water zero-discharge technology that reclaims sodium sulfate comprises the following steps:

[0070] S1. Preprocessing

[0071] Let the incoming water enter the pretreatment unit for pretreatment, remove scaling factors and sundries, and ensure that the hardness of the effluent is less than 150mg / L, and the turbidity of the effluent is less than 5;

[0072] Among them, the incoming water is wastewater containing sodium sulfate salt or concentrated solution of concentrated water after nanofiltration membrane treatment. Considering the economy of this system, the mass concentration of sodium sulfate is not less than 5%, and the influent water is not less than 10m 3 / h;

[0073] The pretreatment unit includes a high-density sedimentation tank and a V-shaped filter conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com