Environment-friendly clean production method for high purity sodium cyanide

A production method and sodium cyanide technology, applied in the direction of metal cyanide, simple alkali metal cyanide, etc., can solve the problems of increasing equipment investment, energy consumption and raw material consumption, and achieve environmental clean production, effective environmental clean production, and equipment Corrosion improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

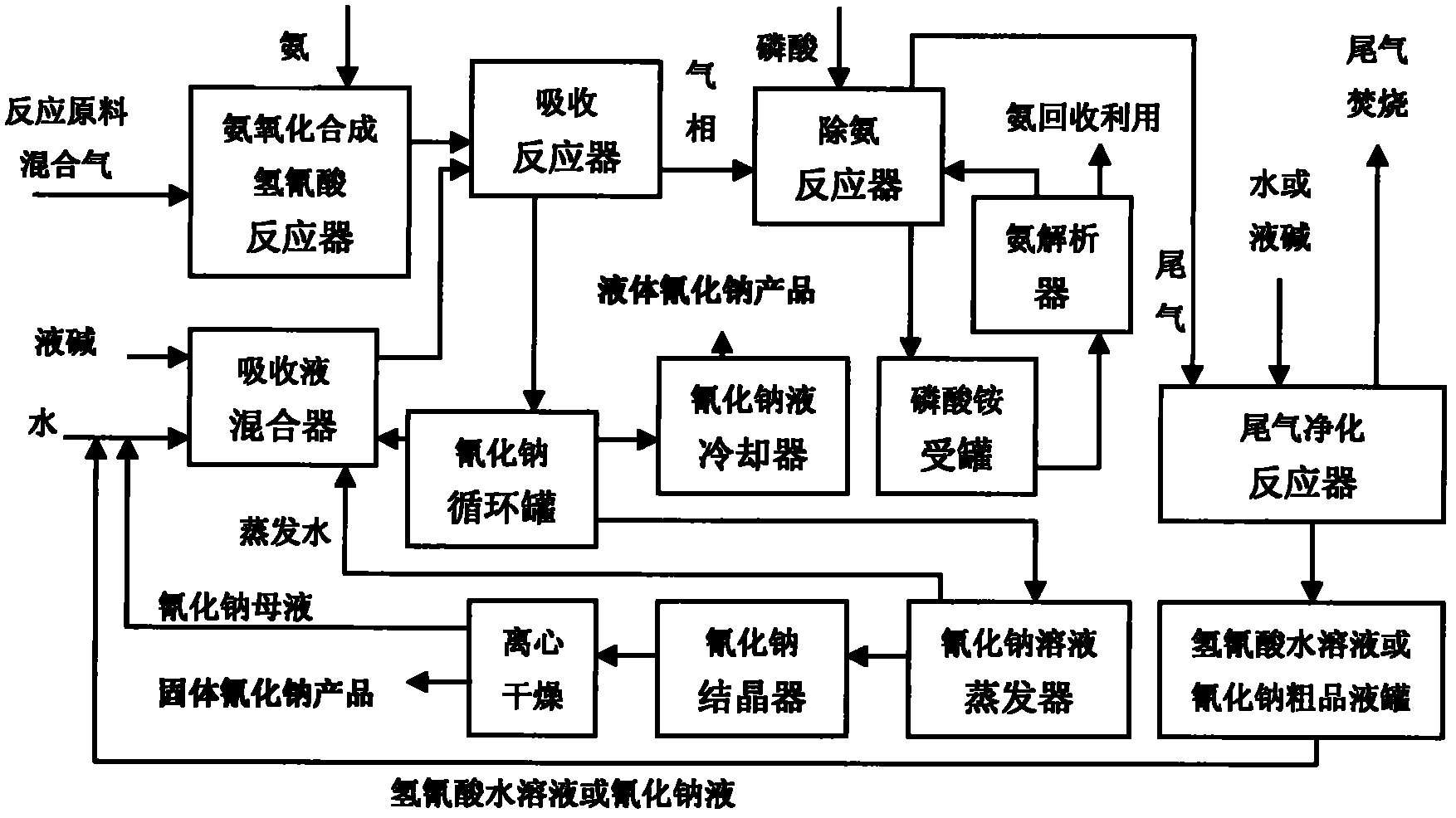

Image

Examples

Embodiment

[0035] Embodiment: the synthetic gas of hydrogen cyanide is synthesized by the ammoxidation of natural gas by Angle's method, and the high-purity sodium cyanide aqueous solution is obtained directly by the absorption reaction of the sodium hydroxide aqueous solution without going through the ammonia removal process, and the free ammonia remains in the tail gas;

[0036] The composition of a certain synthesis gas before the absorption reaction is as follows:

[0037] serial number

[0038] 2

[0039] Sodium cyanide aqueous solution quality table:

[0040] Exterior

[0041] High-purity liquid sodium cyanide products are obtained through cooling and deployment; high-purity solid sodium cyanide products are obtained through concentration, crystallization and centrifugation of high-purity sodium cyanide aqueous solutions;

[0042] Solid sodium cyanide product quality table:

[0043] Exterior

[0044] The components of exhaust gas are as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com