Treatment method of aluminum electrolysis cell waste fireproof material

A technology of refractory materials and aluminum electrolytic cells, which is applied in the field of metallurgy and the environment, can solve problems such as harmful effects on the environment around groundwater, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

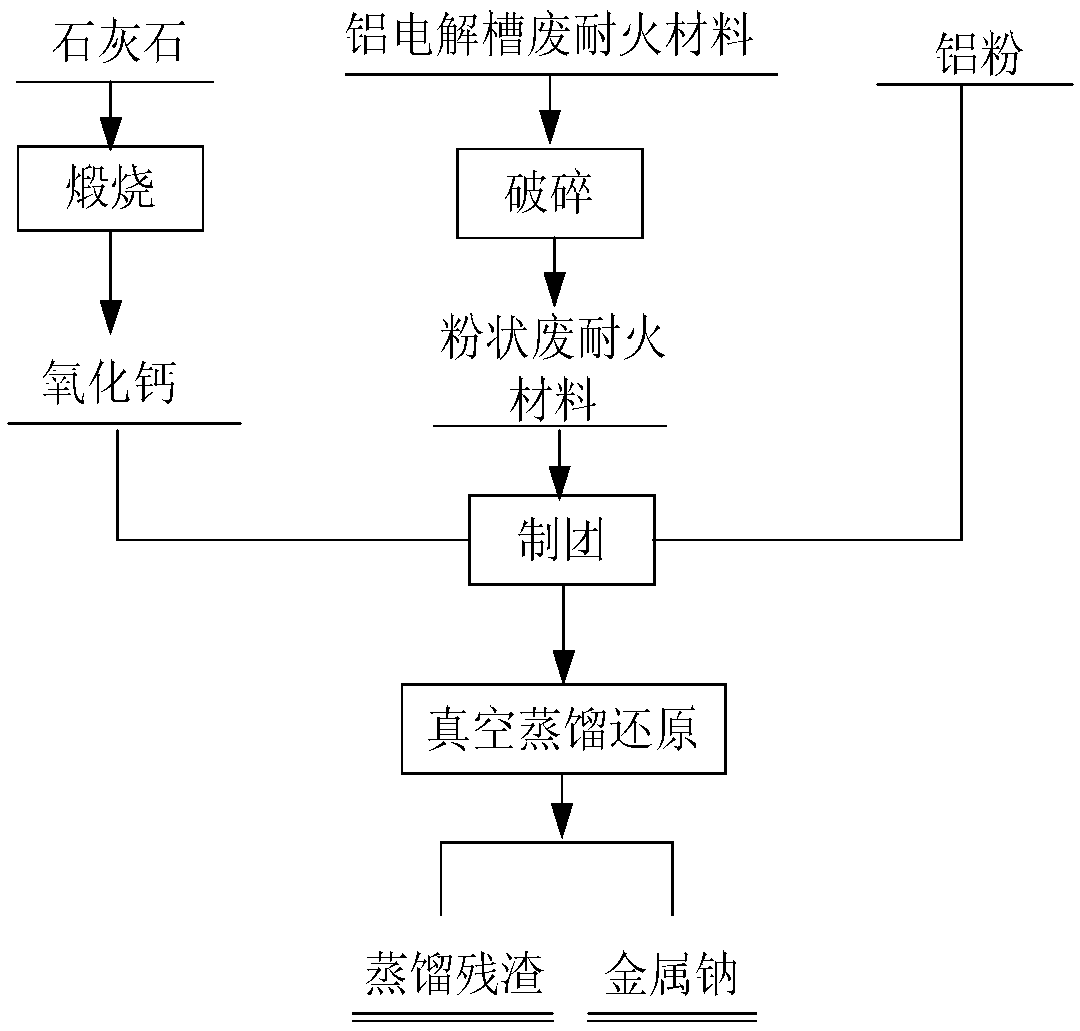

[0052] A kind of processing method of waste refractory material of aluminum electrolytic cell, its processing technology is as follows figure 1 shown, including the following steps:

[0053] Take 200g of waste refractory materials from an aluminum electrolytic cell from an electrolytic aluminum plant, and the waste cathode anti-seepage material contains Al 2 o 3 29.81%, F6.88%, Ca 1.35%, Na 20.03%, SiO 2 41.21%. Grind the cathode anti-seepage material to a particle size below 120 mesh, calcinate 120g of calcium carbonate at a temperature of 1050°C for 2 hours to obtain calcium oxide, and then mix the pulverized waste refractory material with calcium oxide and aluminum powder evenly to form a pellet , the amount of calcium oxide added is 80g, the amount of aluminum powder added is 20g, the pellet making pressure is 60MPa, the diameter of the pellets produced is 30mm, and the height is 20mm. Put the prepared agglomerate into a reducing distillation tank, vacuumize to the re...

Embodiment 2

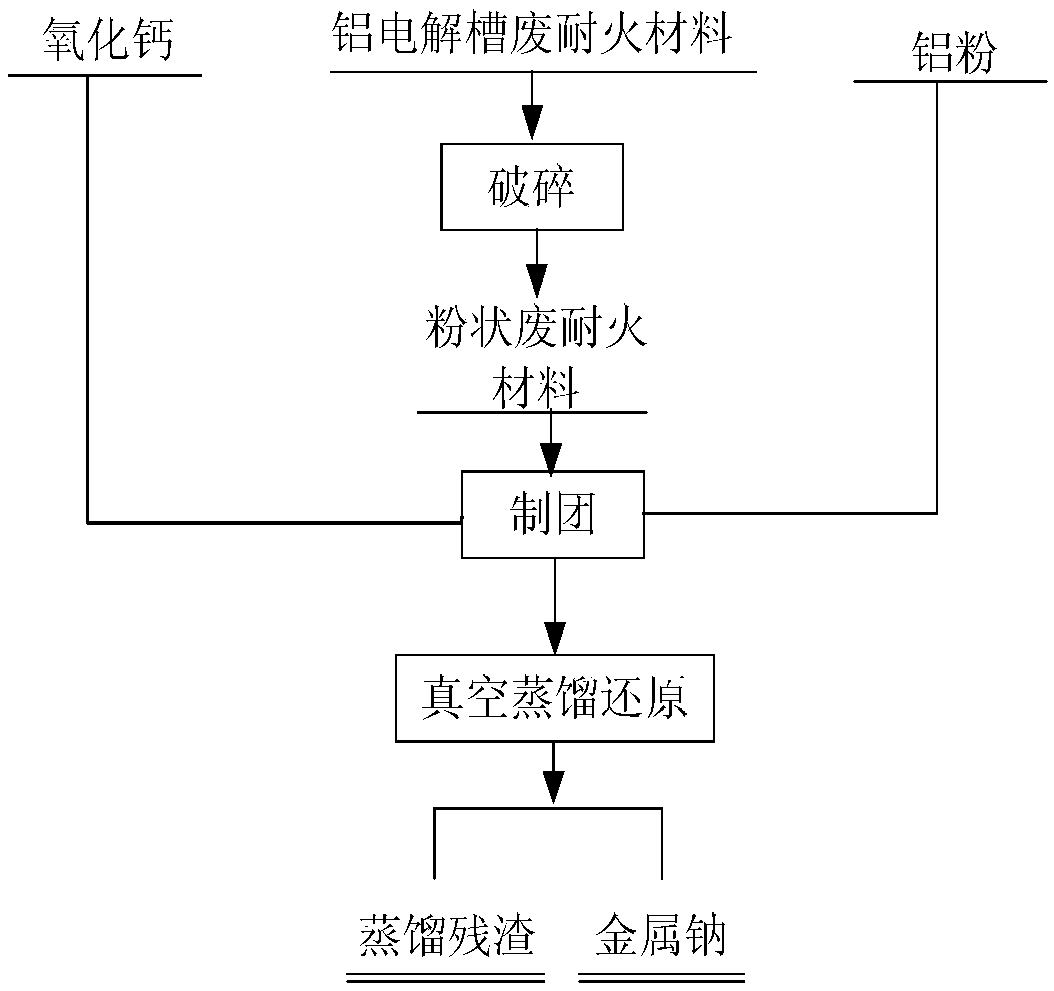

[0055] A kind of processing method of waste refractory material of aluminum electrolytic cell, its processing technology is as follows figure 2 shown, including the following steps:

[0056] Take 200g of waste refractory materials from an aluminum electrolytic cell from an electrolytic aluminum plant, and the waste cathode anti-seepage material contains Al 2 o 3 21.81%, F 5.18%, Ca 1.25%, Na 22.23%, K 3.03%, SiO 2 45.87%. Grind the cathode anti-seepage material to a particle size below 200 mesh, then mix the crushed waste refractory material with 100 g of calcium oxide and 25 g of aluminum powder to form a pellet. The agglomerate taken has a diameter of 30 mm and a height of 25 mm. Put the prepared agglomerate into a reducing distillation tank, vacuumize to the residual pressure in the tank of 20Pa, the reduction temperature is 1100°C, and the reduction time is 2h. After reduction, obtain the sodium-potassium alloy of 51g liquid state on the crystallizer, the X-ray diff...

Embodiment 3

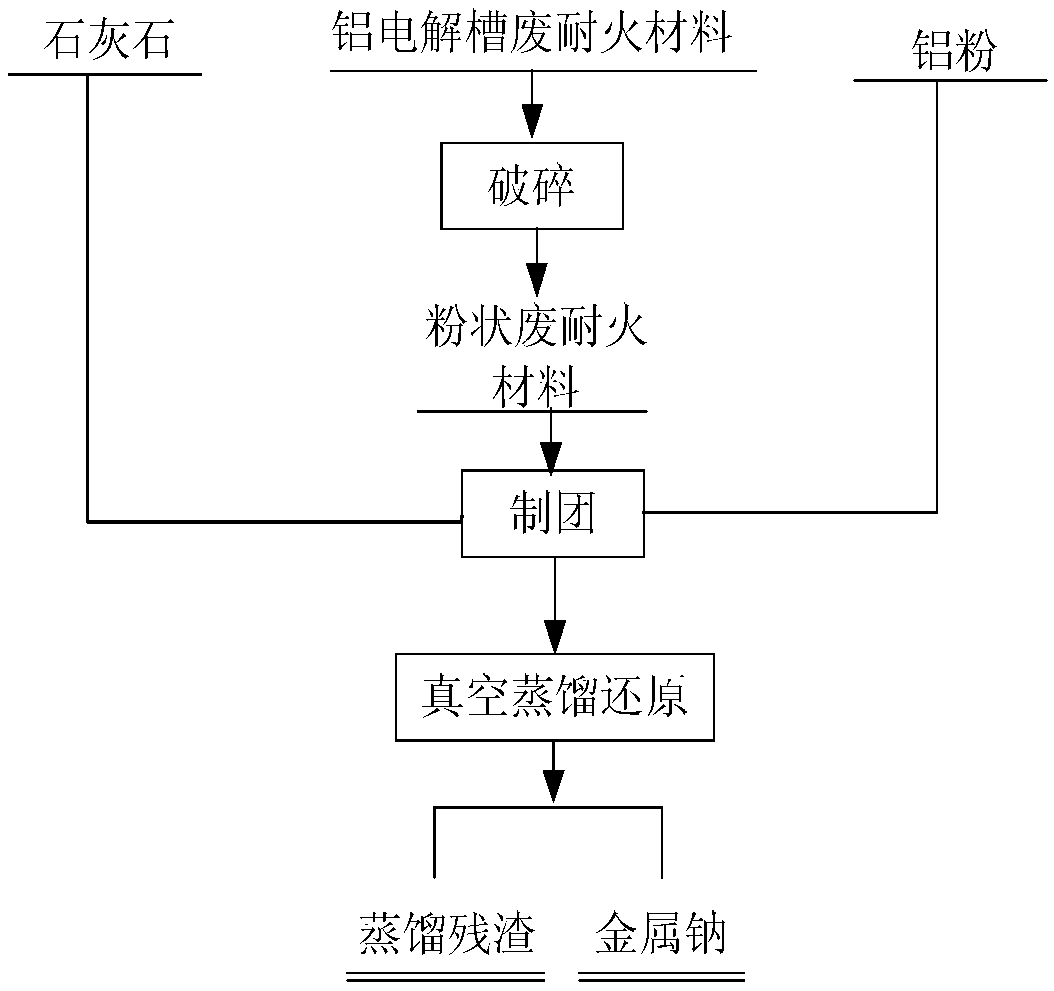

[0058] A kind of processing method of waste refractory material of aluminum electrolytic cell, its processing technology is as follows image 3 shown, including the following steps:

[0059] Take 200g refractory bricks from the bottom of the cathode carbon block of an electrolytic aluminum plant. The refractory bricks are also corroded by the infiltrated electrolyte to be melted together with the anti-seepage material. The main component of the waste refractory bricks is Al 2 o 3 41.23%, F 3.81%, Na8.23%, SiO 2 45.87%. Crush the refractory bricks to a particle size of less than 0.75mm, then mix them with 100g of limestone and 10g of aluminum powder and make agglomerates at a pressure of 100MPa. The residual pressure is 100Pa, the reduction temperature is 1200°C, and the reduction time is 4h. After reduction, 16g of solid metal sodium was obtained on the crystallizer near the heating zone, and the distillation residue was mainly calcium oxide, calcium fluoride, aluminum o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com