High-boiling point monocrystalline silicon wafer surface texturing additive and using method thereof

A single crystal silicon wafer and additive technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve problems such as excessive corrosion, aggravated environmental pollution, and increased waste water treatment costs, so as to reduce production costs and eliminate Effects of environmental pollution and high utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

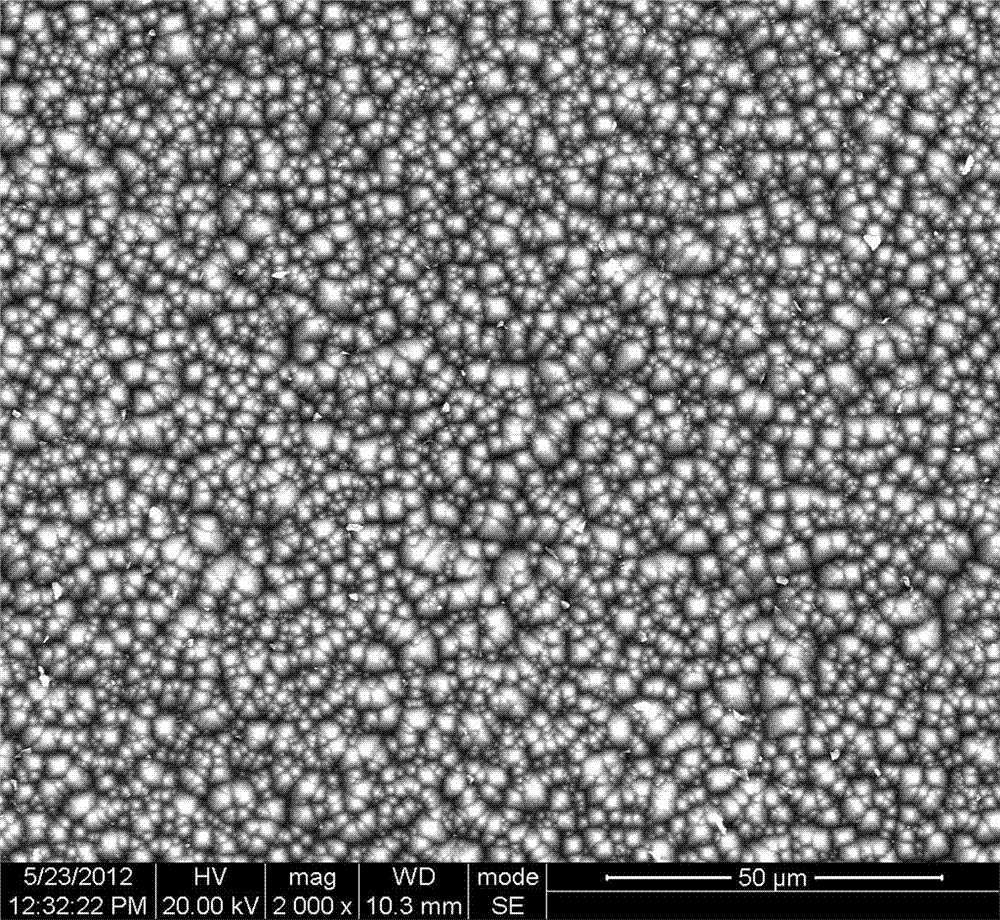

[0029] To prepare alcohol-free single crystal texturing additives, dissolve 10g of sodium alginate, 18g of trisodium phosphate, 2g of sodium lauryl sulfate, 1.5g of vitamin C, and 25g of propylene carbonate into 1L of deionized water to obtain an alcohol-free single crystal. fleece additives. Add 2000g of sodium hydroxide and 1L of alcohol-free single crystal texturing additive into 100L of deionized water to obtain a texturing solution. Raise the temperature of the texturing solution to 85°C, and then immerse the monocrystalline silicon wafer for solar cells in the texturing solution for texturing. The texturing time is 800s. The size of the pyramid textured surface of the obtained silicon wafer is 2-3 μm as detected by scanning electron microscopy, and Uniform size.

Embodiment 2

[0031] To prepare alcohol-free monocrystalline texturing additives, dissolve 15g sodium alginate, 27g trisodium phosphate, 3g sodium lauryl sulfate, 2.25g vitamin C, and 37.5g propylene carbonate into 1.5L deionized water to obtain alcohol-free monocrystalline Crystal Texturing Additive. Add 3000g of sodium hydroxide and 1.5L of alcohol-free single crystal texturing additive into 100L of deionized water to obtain a texturing solution. Raise the temperature of the texturing solution to 75°C, and then immerse the monocrystalline silicon wafer for solar cells in the texturing solution for texturing. The texturing time is 1000s. The size of the pyramid textured surface of the obtained silicon wafer is 2-3 μm as detected by the scanning electron microscope, and Uniform size.

Embodiment 3

[0033] To prepare alcohol-free single crystal texturing additives, dissolve 20g sodium alginate, 36g trisodium phosphate, 4g sodium lauryl sulfate, 3g vitamin C, and 50g propylene carbonate into 2L deionized water to obtain alcohol-free single crystal texturing additive. Add 4000g of sodium hydroxide and 2L of alcohol-free single crystal texturing additive into 100L of deionized water to obtain a texturing solution. Raise the temperature of the texturing solution to 70°C, and then immerse the monocrystalline silicon wafer for solar cells in the texturing solution for texturing. The texturing time is 800s. The size of the pyramid textured surface of the obtained silicon wafer is 2-3 μm as detected by the scanning electron microscope, and Uniform size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com