Sound absorbing decorative gypsum board and production method thereof

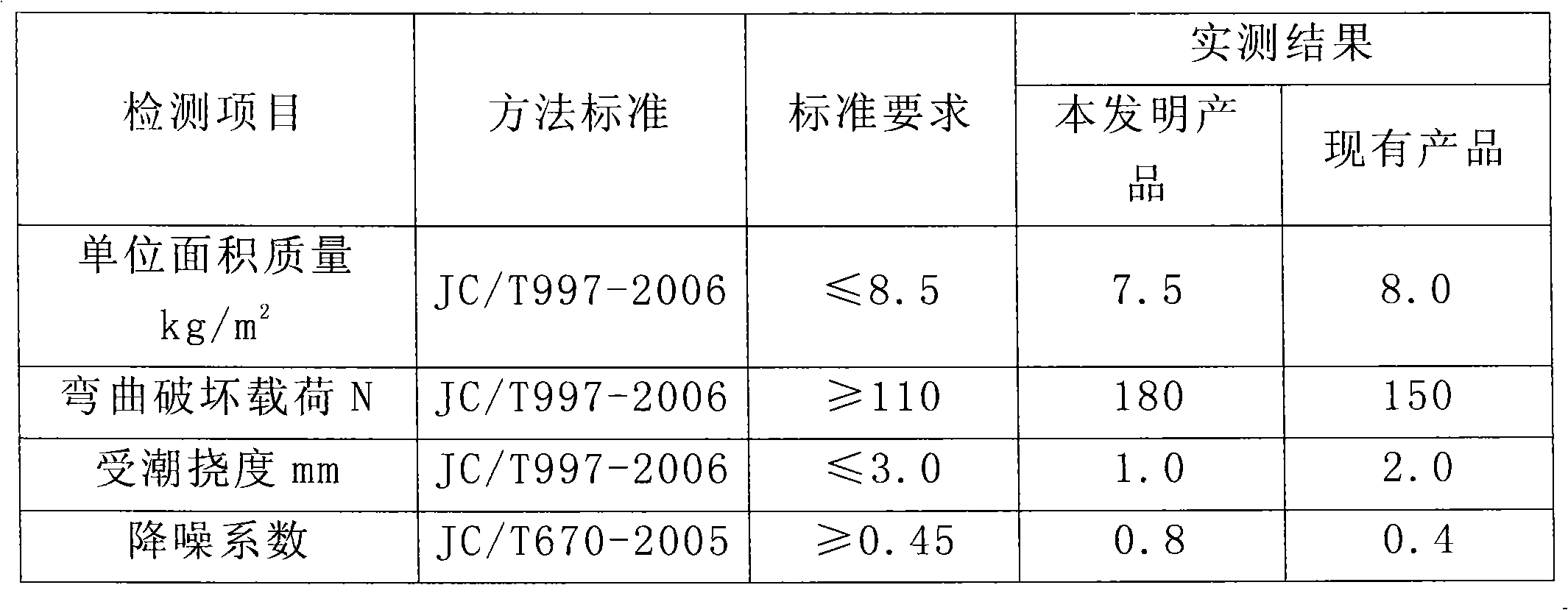

A production method and technology of gypsum board, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of complicated construction, easy damping of decorative sound-absorbing boards, poor impact resistance and waterproofness, etc. Deformation ability, good anti-deformation ability, the effect of strengthening the sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

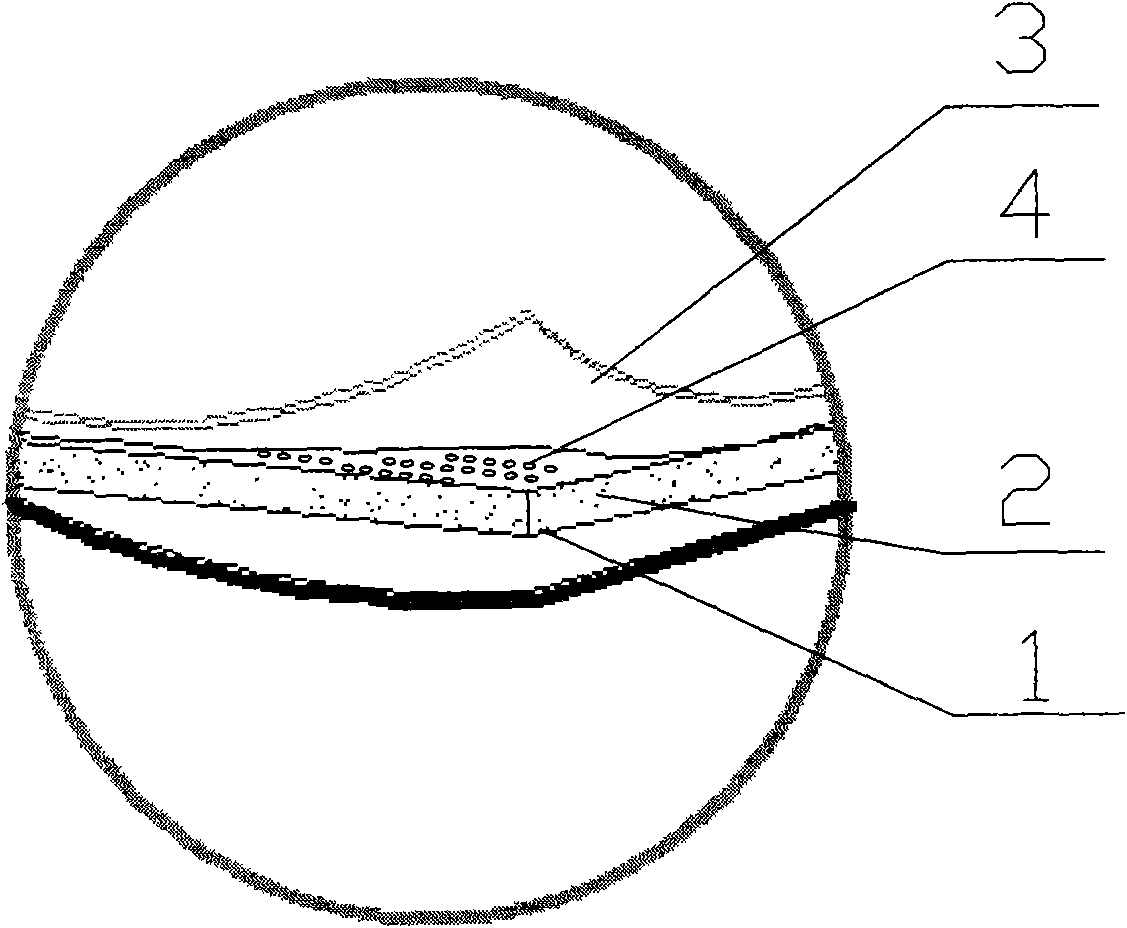

[0010] As shown in the attached figure: a sound-absorbing decorative gypsum board, including aluminum foil 1, paper-faced gypsum board 2, and embossed relief 3, the aluminum foil 1 is attached to the back of the paper-faced gypsum board 2 through epoxy resin glue, and the paper-faced gypsum board 2 The front surface is sprayed with embossed relief 3, the front surface of the plasterboard 2 is pressed with regularly arranged cylindrical sound-absorbing holes 4, the surface of the embossed relief 3 is sprayed with fire-resistant paint, and the weight ratio of the main raw materials of the plasterboard 2 is: 60 parts of desulfurized gypsum, 4 parts of modified starch, 1 part of foaming agent sodium lauryl sulfate, 1 part of glass fiber, 34 parts of water.

[0011] In this embodiment, the aluminum foil 1 is selected as the auxiliary sound-absorbing film, which can not only greatly increase the strength of the sound-absorbing panel, but also improve the sound-absorbing function and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com