Polymer system in controllable association strength

A technology of polymer and cyclodextrin polymer, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of changing molecular configuration, uncontrollable system viscosity, increasing design and synthesis costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

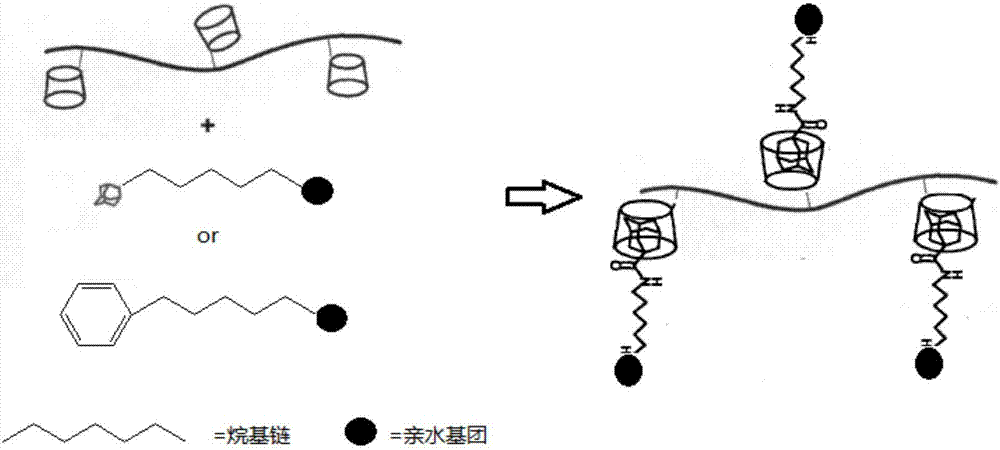

[0018] Example 1 Application of the polymer system with controllable association strength

[0019] The steps are as follows: add 0.15g linear cyclodextrin polymer to 100mL water, fully dissolve at 50°C, use a viscometer at a shear rate of 7.34s - The maximum viscosity under the condition is 180mPa·s. Add 0.002g, 0.003g and 0.004g of adamantane-12 alkyl sodium sulfate slowly, stir and dissolve, and measure the viscosity of the system under the same conditions as 210mPa·s, 280mPa·s and 320mPa·s respectively.

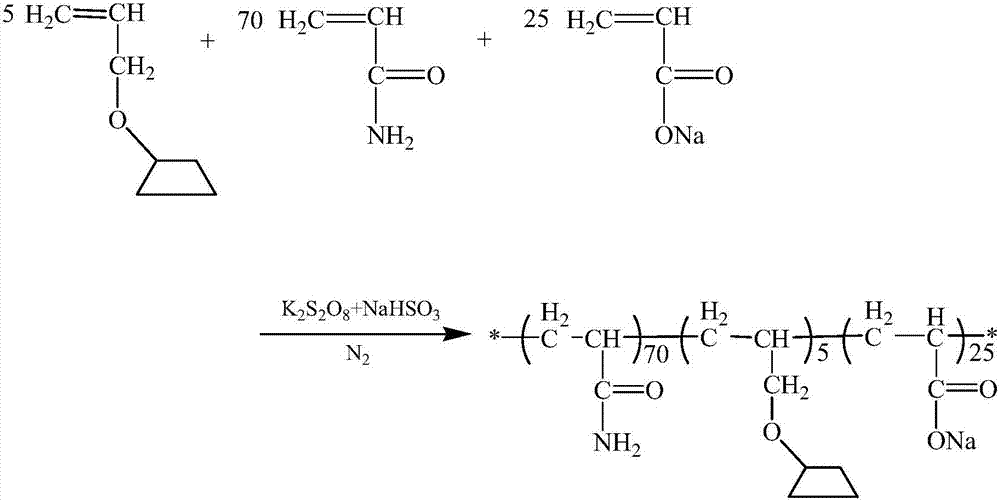

[0020] The linear cyclodextrin polymer has a molecular weight of 12 million and a degree of hydrolysis of 25%. It is prepared by the following method: allyl-β-cyclodextrin, acrylamide and sodium acrylate are polymerized to obtain a linear cyclodextrin Dextrin polymer, wherein, the molar ratio of allyl-β-cyclodextrin, acrylamide and sodium acrylate is 5:70:25, and the reaction conditions are: the total concentration is 25wt%; the reaction temperature is 30°C; Ammonium per...

Embodiment 2

[0021] Example 2 Application of the polymer system with controllable association strength

[0022] The steps are as follows: 0.20g modified Nano-SiO 2 Add the star-shaped polymer cyclodextrin polymer into 100mL water, fully dissolve at 60°C, use a viscometer at a shear rate of 7.34s - The maximum viscosity under the condition is 150mPa·s. Add 0.002g, 0.003g and 0.004g of adamantane-12 alkyl sodium sulfate slowly, stir and dissolve, and measure the viscosity of the system under the same conditions as 180mPa·s, 220mPa·s and 260mPa·s respectively.

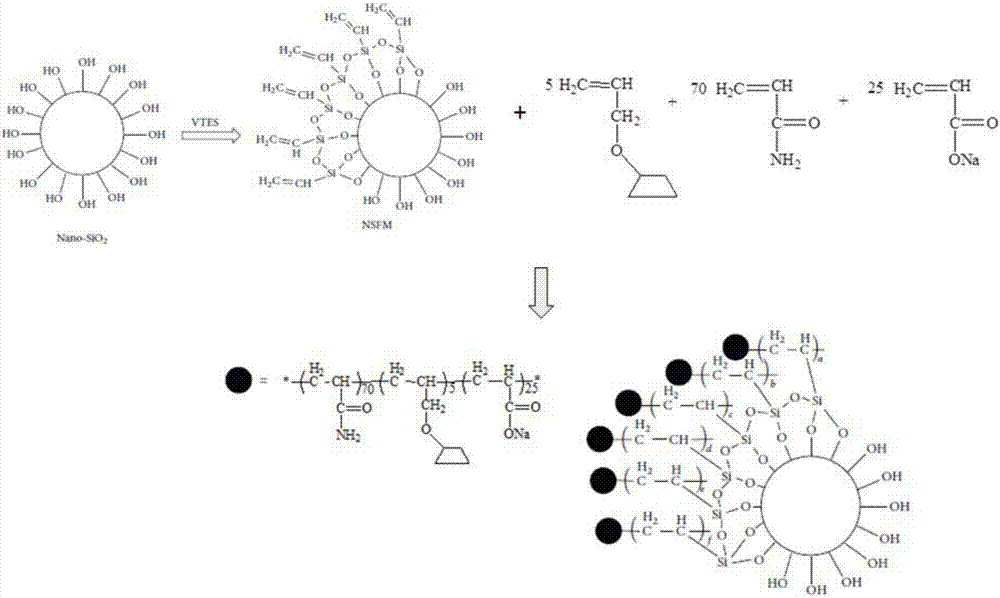

[0023] The modified Nano-SiO 2 Star polymer cyclodextrin polymer, made of Nano-SiO 2 After surface silane coupling to form modified nanoparticles containing olefins on the surface, it is formed by free radical polymerization with allyl-β-cyclodextrin, acrylamide and sodium acrylate, with a molecular weight of 8 million and a degree of hydrolysis of 25%. The preparation method is as follows: First, the Nano-SiO 2 The surface is si...

Embodiment 3

[0024] Example 3 Application of the polymer system with controllable association strength

[0025] The steps are as follows: add 0.15g linear cyclodextrin polymer to 100mL water, fully dissolve at 50°C, use a viscometer at a shear rate of 7.34s - The maximum viscosity under the condition is 200mPa·s. Slowly add 0.002g, 0.003g and 0.004g of benzyl-12 alkyl sodium sulfate respectively, stir and dissolve, and measure the viscosity of the system under the same conditions as 240mPa·s, 300mPa·s and 330mPa·s respectively.

[0026] The preparation method of the linear cyclodextrin polymer is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com