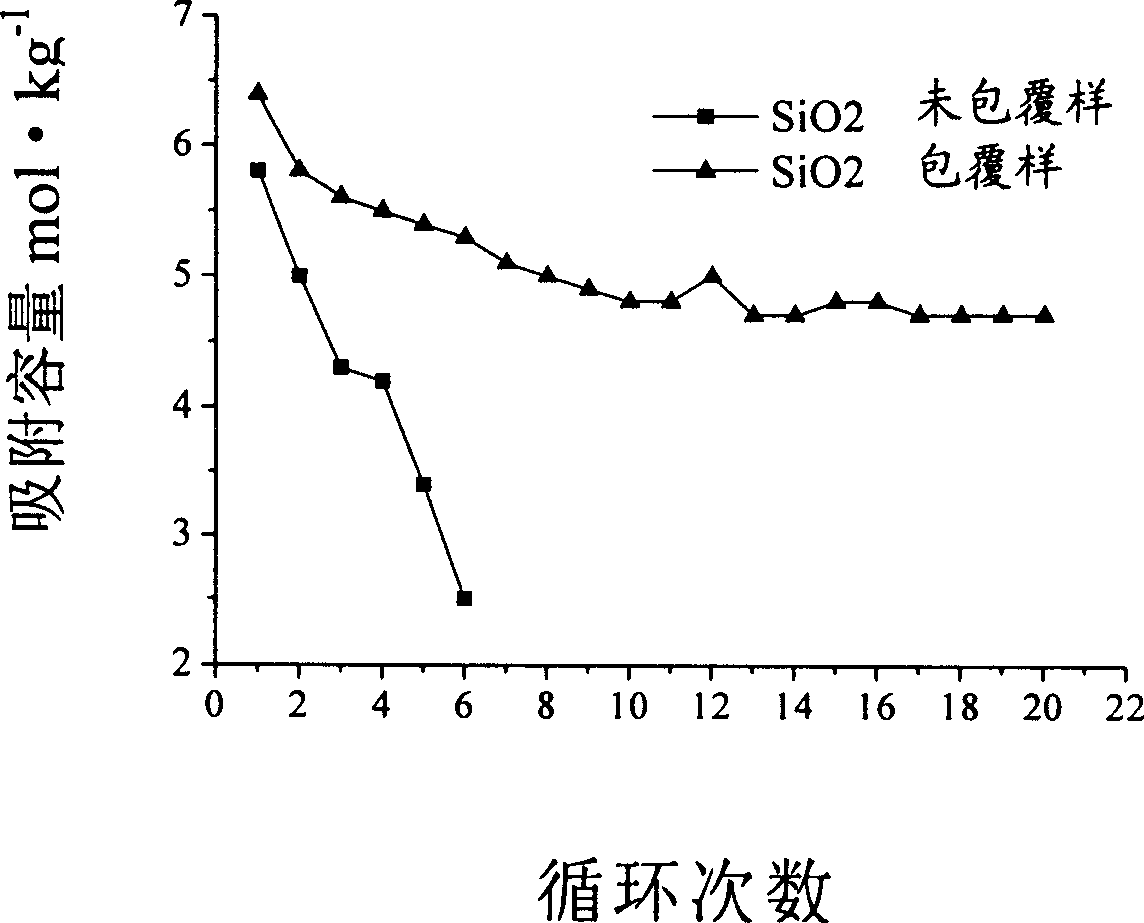

High temperature carbon dioxide adsorbent containing silicon nano calcium oxide, its preparation process and application in hydrogen production process

A technology of carbon dioxide and calcium oxide, applied in chemical instruments and methods, silicon compounds, separation methods, etc., can solve the problems of poor cycle adsorption stability, difficult industrial production, high regeneration temperature, etc., and achieve low processing cost and simple method , the effect of reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Nano CaCO 3 Mix directly with forming agent to form adsorbent

[0022] 75 CaCO 3 , 25 kaolin, of which CaCO 3 It is nano powder with a particle size of 40-50nm, and kaolin is a micron powder with a particle size of 1-3μm. Nano CaCO 3 Mix evenly with kaolin at a ratio of 3:1, add appropriate amount of water, stir to form a paste, extrude, and dry. And calcined at 600-800°C to make ordinary nano-calcium oxide high-temperature carbon dioxide adsorbent.

Embodiment 2

[0023] Embodiment 2: the preparation method 1 of the adsorbent treated by surface silicon coating

[0024] Nano-CaCO 3 The average particle size is 40-50nm, Na 2 SiO 3 .9H 2 O dosage is SiO 2 / CaCO 3 = 4.5%. CaCO 3 It is configured into a 10% suspension, and the dispersant sodium hexametaphosphate is added in an amount of 0.002g / ml. The temperature of the suspension was raised to 60°C, and sodium silicate and 1% dilute sulfuric acid solution were slowly added. Aged at around pH 7. Vacuum filtration and washing until there is no sulfate ion. Dry to constant weight at 75 CaCO 3 , 25 kaolin (particle size 1-3μm) mixed evenly, adding an appropriate amount of water, stirring into a paste, extruding, and drying. And calcined at 600-800°C to make silicon-containing nano-calcium oxide high-temperature carbon dioxide adsorbent.

Embodiment 3

[0025] Embodiment 3: the preparation method 2 of the adsorbent treated with silicon coating on the surface

[0026] Nano-CaCO 3 The average particle size is 70-80nm, Na 2 SiO 3 .9H 2 O dosage is SiO 2 / CaCO 3 = 10.0%. CaCO 3 It is configured into a 10% suspension, and the dispersant sodium hexametaphosphate is added in an amount of 0.002g / ml. The temperature of the suspension was raised to 80°C, and sodium silicate and 4% dilute sulfuric acid solution were slowly added. Aged at pH 8. Vacuum filtration and washing until there is no sulfate ion. Dry to constant weight, according to 85CaCO 3 , 15% of kaolin (particle size 1-3μm) is mixed evenly, adding an appropriate amount of water, stirring into a paste, and extruding. The shaped adsorbent is dried and calcined at 600-800° C. to produce a silicon-containing nano-calcium oxide high-temperature carbon dioxide adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com