Preparing method of composite styrene-acrylic emulsion containing silicon dioxide

A technology of silicon dioxide and styrene-acrylic emulsion, applied in instruments, inks, coatings, etc., can solve the problems of affecting the stability of styrene-acrylic emulsion, affecting the comprehensive performance of emulsion, and producing residues due to directional coagulation of latex beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

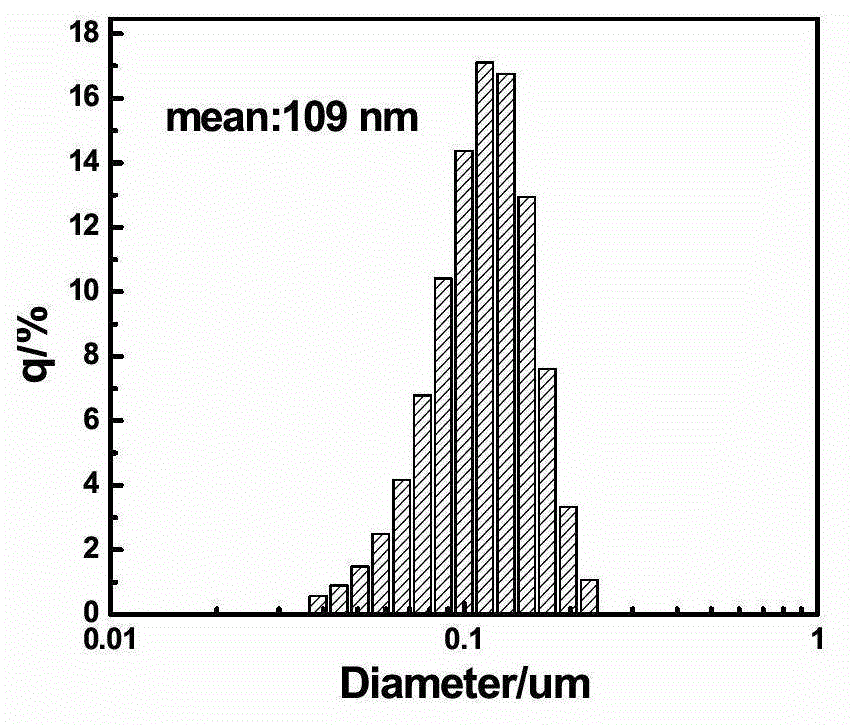

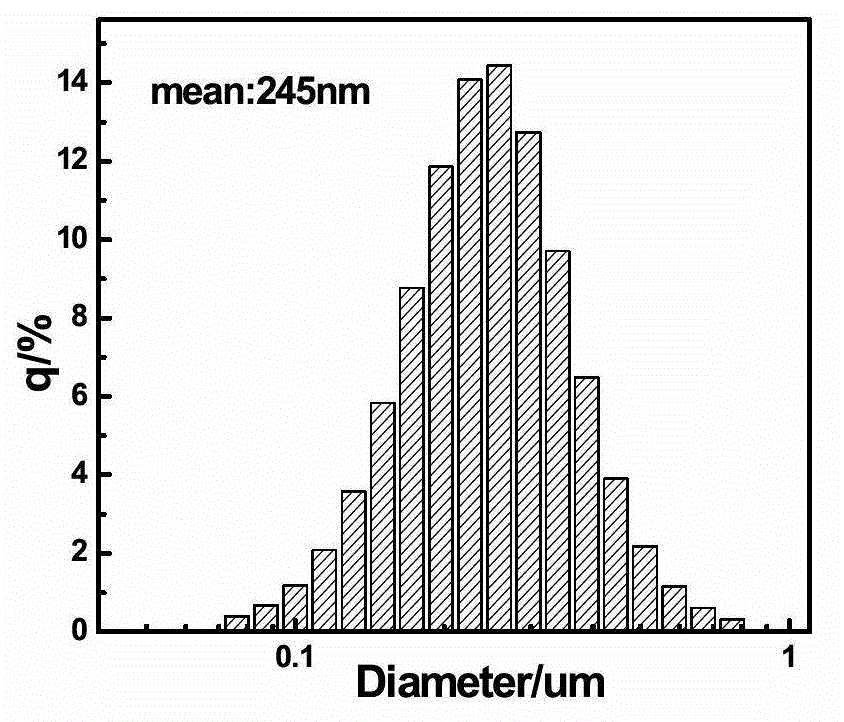

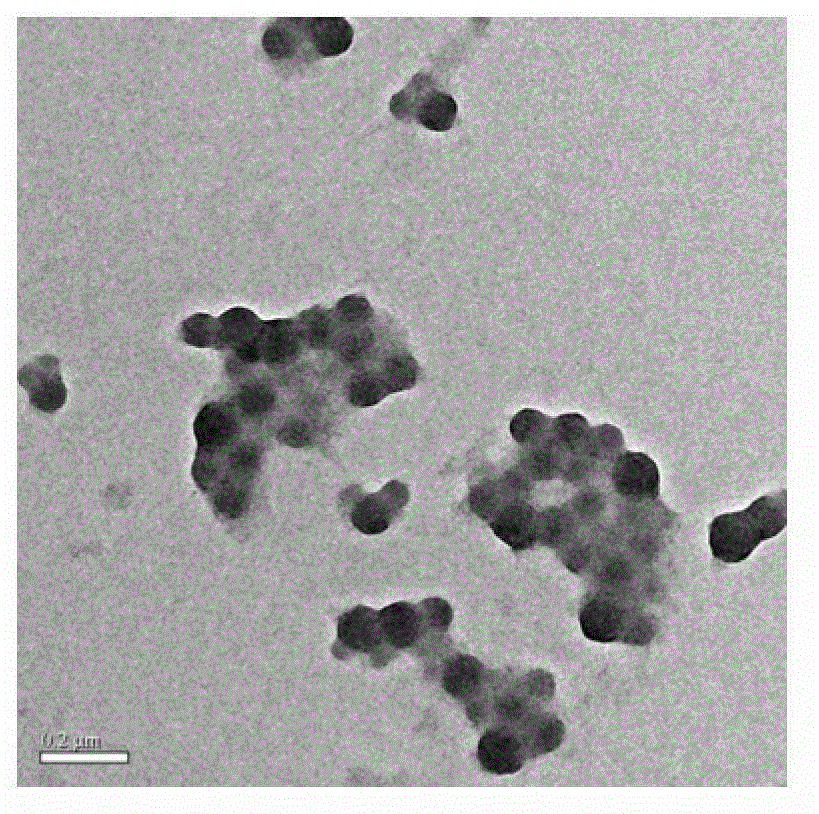

Image

Examples

Embodiment 1

[0031] Add 20ml of deionized water and 5ml of ethanol into a 250ml four-necked flask equipped with a condenser tube, a mechanical stirrer, and 2 constant-pressure dropping funnels, and adjust the pH value to 8.0-9.5 with ammonia water to obtain an alcoholic solution. Mix the mixed monomer containing 0.8 gram of styrene, 0.2 gram of butyl acrylate, 0.08 gram of acrylic acid and 4.50 gram of ethyl orthosilicate, and ultrasonically disperse for 30 minutes to obtain a mixed solution of ethyl orthosilicate; The mixed solution was added to the above alcohol solution at one time, stirred under the protection of nitrogen, and reacted at room temperature for 5 hours to obtain a silica / mixed monomer dispersion.

[0032] Add 0.25 g of vinyltrimethoxysilane coupling agent dropwise to the silica / mixed monomer dispersion and continue to react at room temperature for 3 hours under nitrogen protection to obtain a silane-modified silica / mixed monomer dispersion.

[0033] Add 45ml of deionized ...

Embodiment 2

[0037] Add 20ml of deionized water and 5ml of ethanol into a 250ml four-necked flask equipped with a condenser tube, a mechanical stirrer, and 2 constant-pressure dropping funnels, and adjust the pH value to 8.0-9.5 with ammonia water to obtain an alcoholic solution. Mix the mixed monomer containing 0.8 g of styrene, 0.2 g of β-hydroxyethyl acrylate, 0.08 g of acrylic acid and 4.50 g of ethyl orthosilicate, and ultrasonically disperse for 30 minutes to obtain a mixed solution of ethyl orthosilicate; The ethyl ester mixed solution was added to the above alcohol solution at one time, stirred under the protection of nitrogen, and reacted at room temperature for 8 hours to obtain a silica / mixed monomer dispersion.

[0038] Add 0.25 g of vinyltriethoxysilane coupling agent dropwise to the silica / mixed monomer dispersion and continue to react at room temperature under nitrogen protection for 4 hours to prepare a silane-modified silica / mixed monomer dispersion.

[0039] Add 45ml of d...

Embodiment 3

[0043] Add 20ml of deionized water and 5ml of ethanol into a 250ml four-necked flask equipped with a condenser tube, a mechanical stirrer, and 2 constant-pressure dropping funnels, and adjust the pH value to 8.0-9.5 with ammonia water to obtain an alcoholic solution. Mix the mixed monomers containing 3.2 g of styrene, 0.96 g of β-hydroxypropyl acrylate, 0.16 g of acrylamide and 16.6 g of ethyl orthosilicate, and disperse ultrasonically for 30 minutes to obtain a mixed solution of ethyl orthosilicate; The ethyl acetate mixed solution was added to the above alcohol solution at one time, stirred under the protection of nitrogen, and reacted at room temperature for 10 hours to obtain a silica / mixed monomer dispersion.

[0044] Add 0.03 g of vinyl tris(β-methoxyethoxy)silane coupling agent dropwise to the silica / mixed monomer dispersion and continue to react at room temperature under nitrogen protection for 0.5 hours to obtain silane-modified silica / Mix the monomer dispersion.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com