Modified nano-drilling fluid treating agent for restraining mud shale expansion

A kind of drilling fluid treatment agent and nano technology, applied in drilling composition, chemical instruments and methods, etc., to achieve the effect of reducing fluid loss, good toughness and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0008] Example 1: Modified nano-drilling fluid treatment agent for inhibiting shale expansion and preparation method thereof

[0009] (1) Experimental formula and conditions:

[0010] The modified nano-drilling fluid treatment agent for inhibiting shale expansion is composed of nano-SiO 2 , acrylamide, silane coupling agent KH-550, ammonium persulfate, toluene, and distilled water. The quality of each raw material is in grams and some properties are: nano-SiO 2 5-10g, density 2.33, specific surface area 150m 2 / g, particle size 20-40nm (powder particle size less than 100nm belongs to nanoparticles); acrylamide 8g, molecular weight 71.08; silane coupling agent KH-5500.8g; ammonium persulfate initiator 0.2g; toluene 300g; distilled water 500g ; Nitrogen atmosphere for 30 minutes, the pH value was adjusted to 8-8.5, and the temperature of the water bath was controlled at 15-20°C.

[0011] (2) Preparation method of modified nano treatment agent for inhibiting shale expansion: ...

example 2

[0013] Example 2: Prevention of shale expansion test

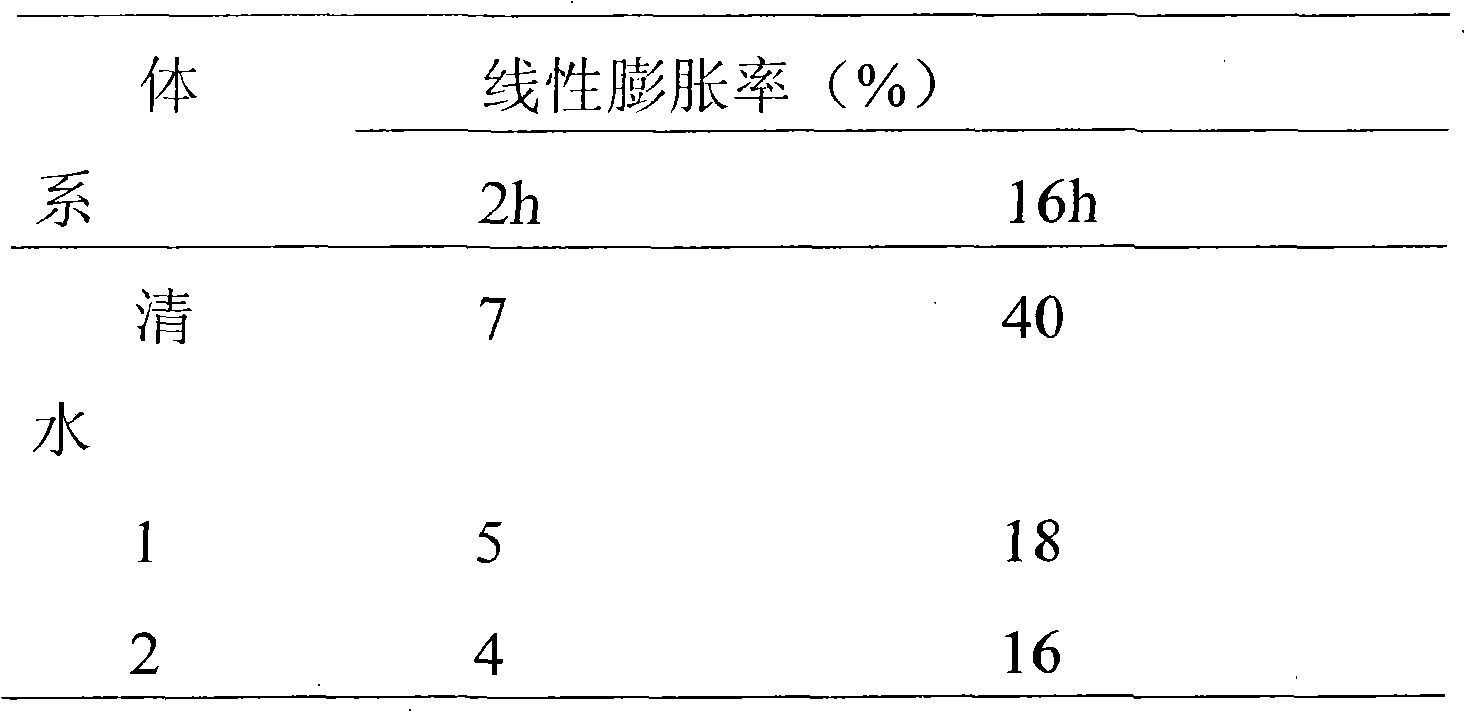

[0014] Configure KCl-PAM drilling fluid, and use a high-temperature and high-pressure shale dilatometer to evaluate the inhibition of the drilling fluid system to shale. Weigh 10g of rock cuttings powder, maintain a pressure of 4MPa on a tablet machine for 5min to obtain a sample tablet, then soak it with the prepared 350mL solution, and measure the linear expansion height during the soaking process on a shale dilatometer. Calculate the linear expansion rate with the expansion rate calculation formula (1-1), and the experimental results are shown in Table 1-1.

[0015] VH=Rt / H×100% (1-1)

[0016] Rt-the linear expansion at time t, mm; H-the original height of the core, mm.

[0017] Table 1-1 Results of rolling dispersion of shale in different media

[0018]

[0019] Note: 1-KCl-PAM drilling fluid; 2-acrylamide graft polymerization modified nano-SiO 2 - KCl-PAM drilling fluid;

[0020] It can be seen from Table 1-1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com