Water-based nano synthetic leather slurry and method for manufacturing nano synthetic leather

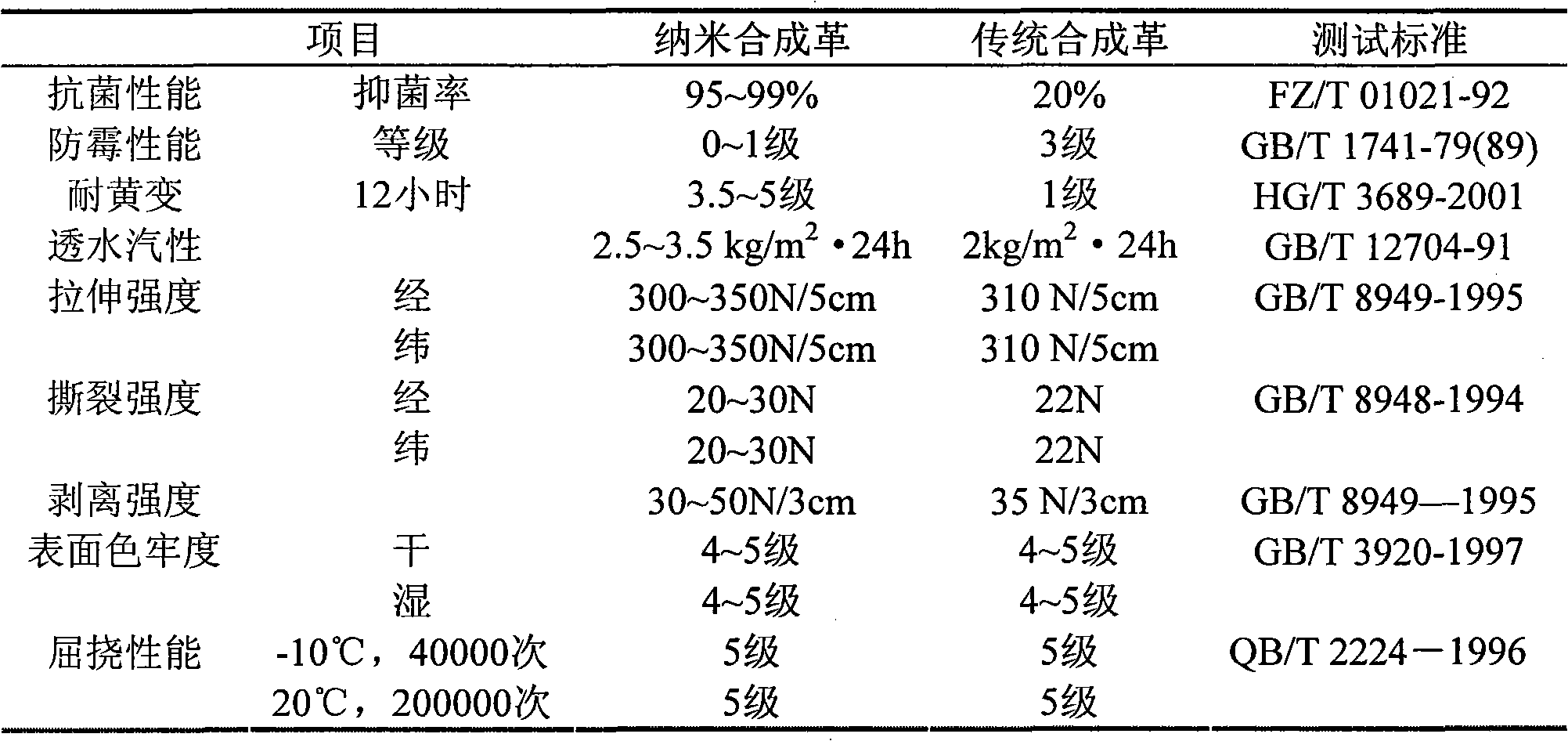

A manufacturing method and technology for synthetic leather, applied in textiles, papermaking, fiber processing, etc., can solve the problems of low air permeability and moisture permeability of synthetic leather, not resistant to yellowing, easy to grow mildew, etc., and achieve excellent antibacterial and mildew resistance, good Effects on storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1 water-based polyurethane / nano-SiO 2 Preparation of complex emulsion

[0043] 100 parts of isophorone diisocyanate, 200 parts of polytetrahydrofuran diol (number average relative molecular weight 2000), 25 parts of castor oil and 4 parts of diethylene glycol were added at room temperature with a stirrer, thermometer and reflux In the reaction vessel of the condenser tube, add 0.35 parts of diisobutyltin dilaurate, react at a temperature of 80-85°C for 2 hours, add 20 parts of dimethylol propionic acid (dissolved with N-methylpyrrolidone), and react at a temperature of 70-75°C ℃ to continue the reaction for 2 hours to obtain a polyurethane prepolymer; cool the prepolymer to 40°C, add 16 parts of triethylamine to neutralize the reaction for 20 minutes, add 44 parts of ethyl orthosilicate precursor solution (made from 24 parts of ethyl orthosilicate and 20 parts of N-methylpyrrolidone), stirred for 30 minutes, and finally added 530 parts of deionized water to emulsify fo...

Embodiment 2

[0055] 1 water-based polyurethane / nano-SiO 2 Preparation of complex emulsion

[0056] 100 parts of toluene diisocyanate, 230 parts of polyoxypropylene diol (number average relative molecular weight 2000), 2 parts of glycerin and 3 parts of 1,4-butanediol were added at room temperature with a stirrer, thermometer and reflux condenser In a reaction vessel, react at a temperature of 70 to 75°C for 2 hours, add 20 parts of dimethylol butyric acid (dissolved in N,N-dimethylacetamide), and continue to react at a temperature of 65 to 70°C for 2 hours to obtain polyurethane pre- polymer; cool the prepolymer to 20°C, add 14 parts of triethylamine to neutralize the reaction for 30 minutes, add 145 parts of orthobutyl silicate precursor solution (composed of 85 parts of orthobutyl silicate and 60 parts of N, N-di methyl acetamide), stirred for 30 minutes, and finally added 670 parts of deionized water to emulsify for 2 hours under high-speed stirring, and added 2.6 parts of ethylenediam...

Embodiment 3

[0068] 1 water-based polyurethane / nano-SiO 2 Preparation of complex emulsion

[0069] 28 parts of hexamethylene diisocyanate, 72 parts of isophorone diisocyanate, 60 parts of polyoxypropylene diol (number average relative molecular weight 1000), 150 parts of polytetrahydrofuran diol (number average relative molecular weight 2000), 22 parts Add castor oil and 2 parts of ethylene glycol into a reaction vessel with a stirrer, a thermometer and a reflux condenser at room temperature, add 0.4 parts of diisobutyltin dilaurate, react at a temperature of 75-80°C for 2 hours, and add 16 parts Dimethylol propionic acid (dissolved with N, N-dimethylformamide), continue to react for 2 hours to obtain a polyurethane prepolymer; cool the prepolymer to 30°C, add 12 parts of triethylamine to neutralize the reaction for 20 minutes, Add 180 parts of ethyl orthosilicate precursor solution (100 parts of ethyl orthosilicate and 80 parts of N,N-dimethylformamide), stir for 30 minutes, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com