Method for preparing industrial grade and food grade phosphoric acid by wet method phosphoric acid

A wet-process phosphoric acid, industrial-grade technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of excessive sodium ions in the purification acid, serious organic phase entrainment in the acid phase, increased process and purification costs, etc. Achieve complete removal, reduce energy consumption, reduce density and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Preparation of technical grade phosphoric acid

[0020] P 2 o 5

SO 4 2-

F

Fe

As

Heavy metals (as Pb)

Chroma

50.4%

3.5%

0.75%

0.3%

0.0014%

0.0025%

>300

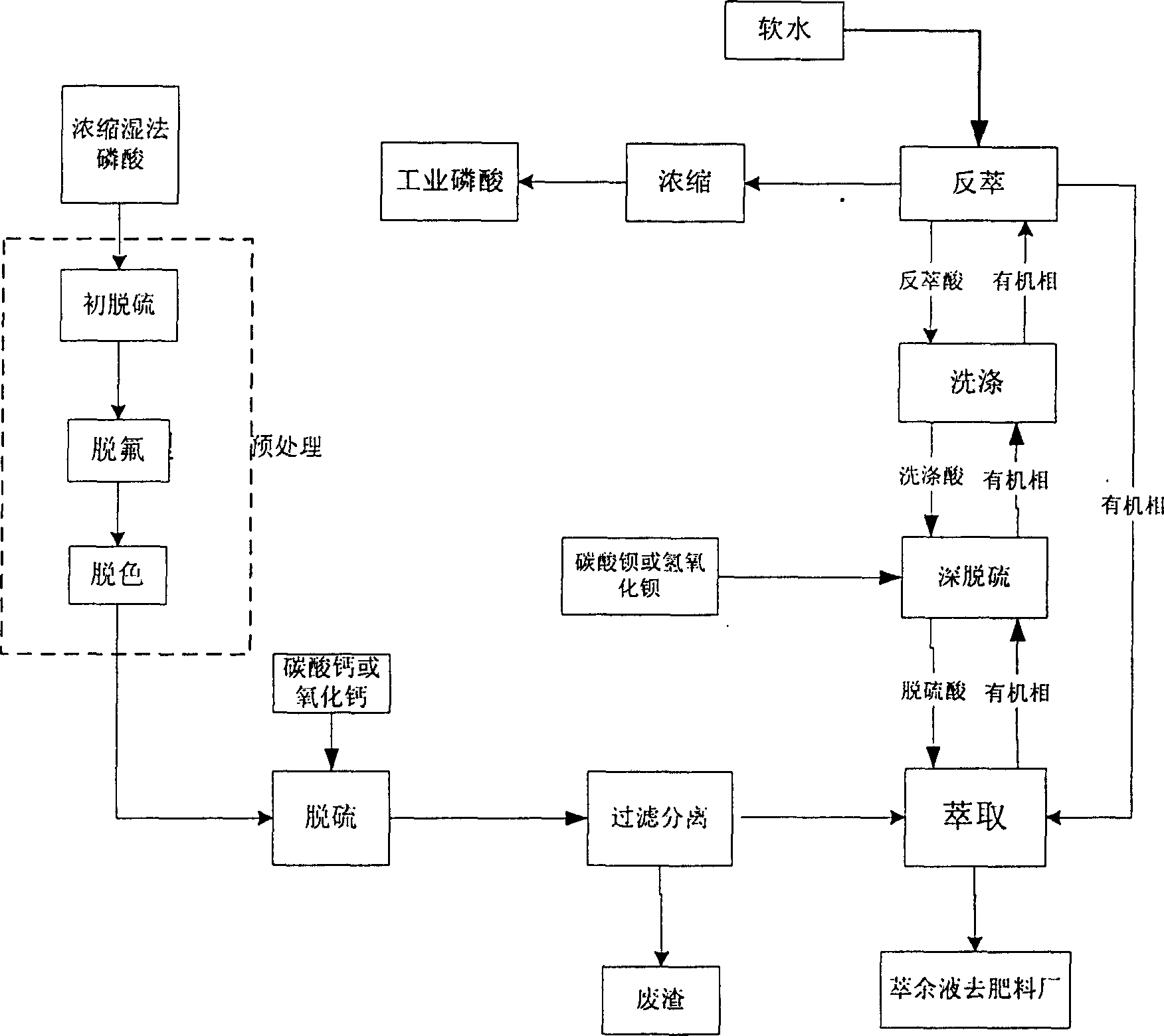

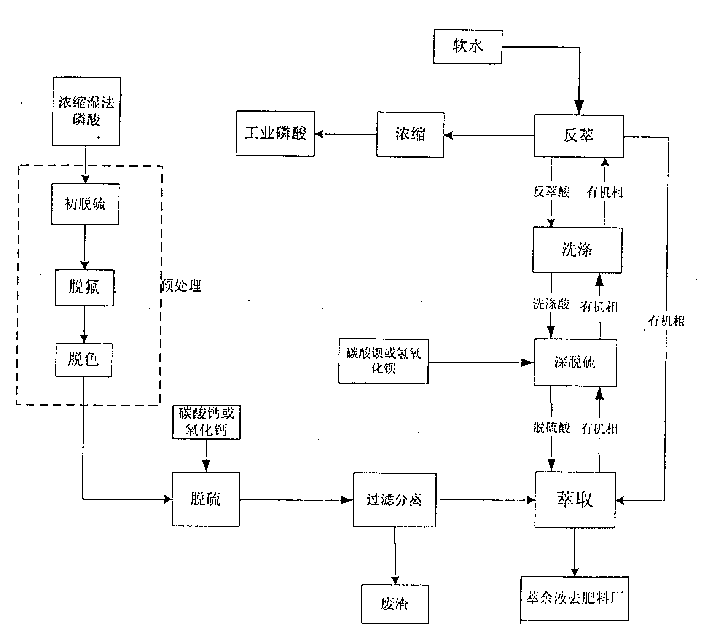

[0021] Continuous production, process steps such as figure 1 As shown, it includes pretreatment, desulfurization, filtration separation, extraction, deep desulfurization, washing, stripping and concentration in sequence.

[0022] (1) Pretreatment

[0023] The pretreatment is carried out in the pretreatment tank, and the desulfurization agent is phosphorus concentrate, according to the amount of SO in phosphoric acid 4 2- 1.1 times of the stoichiometric ratio is added; the defluorination agent is selected from sodium carbonate, and the addition is 1.2 times of the stoichiometric ratio of fluorine content in phosphoric acid; the decolorizing agent is selected from active carbon and diatomite, and the addition of active carbon i...

Embodiment 2

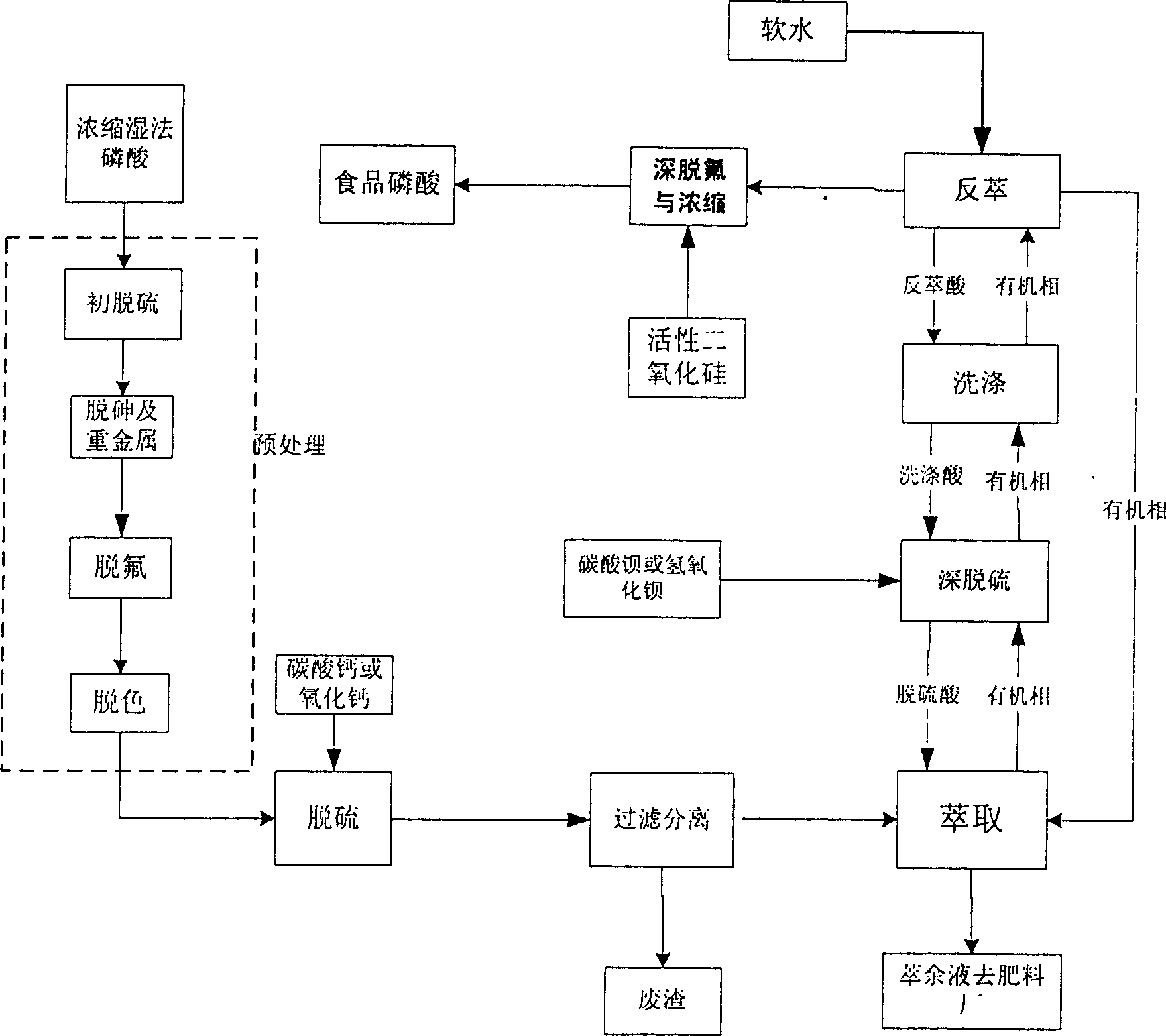

[0039] Embodiment 2: Preparation of food-grade phosphoric acid

[0040] In this embodiment, the composition of the raw material wet-process phosphoric acid used is the same as that in Embodiment 1. Continuous production, process steps such as figure 2 As shown, it includes pretreatment, desulfurization, filtration separation, extraction, deep desulfurization, washing, stripping, deep defluorination and concentration in sequence.

[0041] In the above process steps, except for the pretreatment, deep defluorination and concentration processes, other processes are the same as in Example 1.

[0042]The pretreatment is carried out in the pretreatment tank, and the desulfurization agent is phosphorus concentrate, according to the amount of SO in phosphoric acid 4 2- 1.2 times of the stoichiometric ratio is added; the defluorination agent is selected from sodium carbonate, which is 1.1 times of the stoichiometric ratio of the fluorine content in phosphoric acid; The amount of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com